Mainteance

51

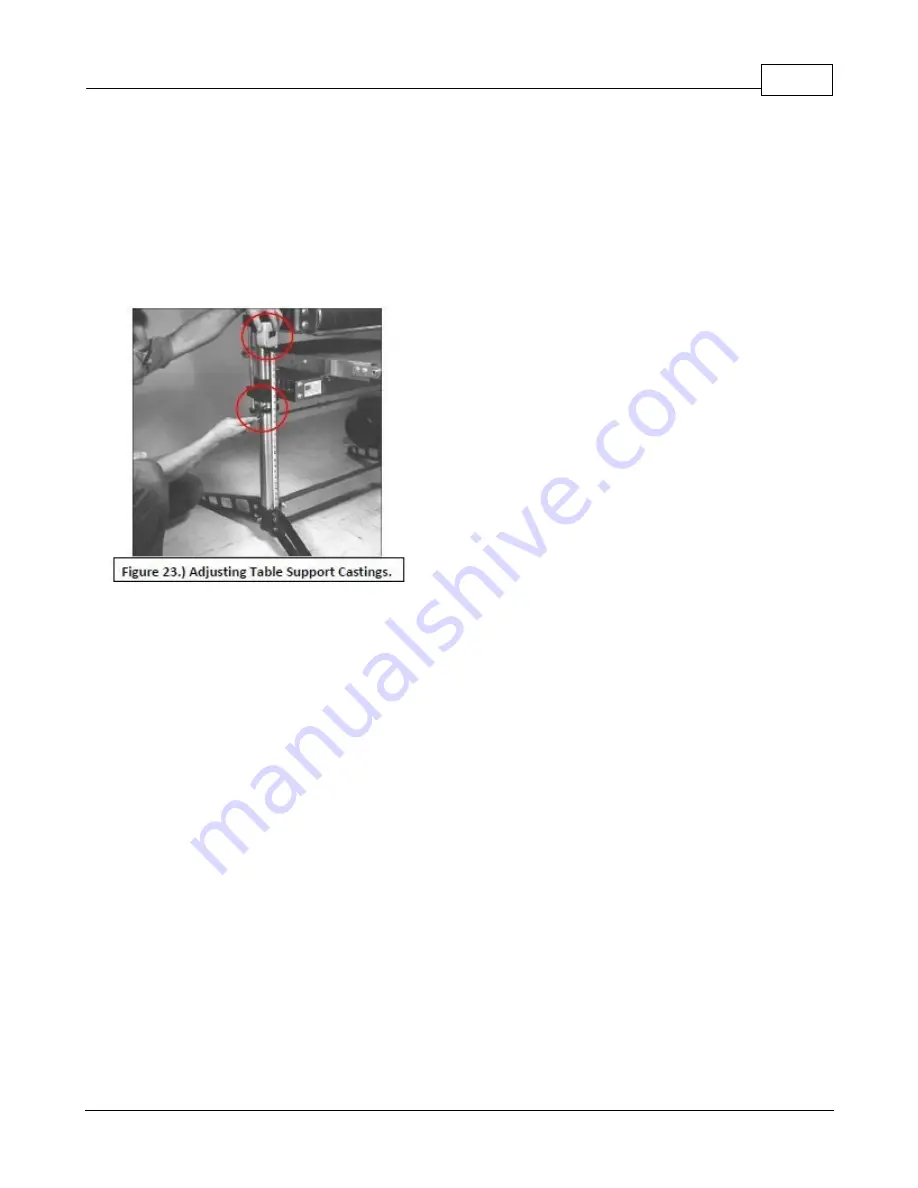

If the conveyor table does not raise and lower easily, measure the distance between the top of the base column

support and the bottom of the table support casting

(See Figure 23)

on both the right (inboard) side and the left

(outboard) side of the machine. Compare these measurements; they should be within 1/16". If not, disengage the

Miter Gear on the Right (inboard) side of the cross bar. Adjust the conveyor bed height using the height adjustment

handle to get the same measurement on both sides. Then re-engage the miter gear on the cross bar. If the

conveyor table is still difficult to raise or lower, the table support castings may need to be recentered on the column

tubes. To do this, loosen the 3/8" x 1-1/4" Button Head Socket Screw in each table support casting, adjust and

tighten the set screws to hold the casting in position. Then tighten the hex head bolts and loosen the set screws.

Summary of Contents for 37 x 2

Page 2: ......

Page 17: ...General Information 17 Castings...

Page 18: ...Double Drum Sander 37 x 2 18 Supermax Specifications...

Page 19: ...General Information 19 Supermax Accessory Supply Check List...

Page 47: ...Mainteance 47...

Page 54: ...Double Drum Sander 37 x 2 54...

Page 56: ...Double Drum Sander 37 x 2 56 Drumhead Assembly Exploded View...

Page 57: ...Drumhead Parts List 57 Drumhead Parts List...

Page 58: ...Double Drum Sander 37 x 2 58...

Page 59: ...Conveyor Exploded View 59 Conveyor Exploded View...

Page 60: ...Double Drum Sander 37 x 2 60 Conveyor Parts List...

Page 61: ...Conveyor Parts List 61...

Page 62: ...Double Drum Sander 37 x 2 62 Exploded Diagrams...

Page 63: ...Parts Lists 63 Parts Lists...

Page 77: ...Disassembly Procedure 77...

Page 79: ...Warranties 79 Warranties Laguna Tools Warranty...

Page 80: ...Double Drum Sander 37 x 2 80 Modifications RMA Policy Laguna Tools Packaging RMA Procedure...

Page 81: ...Warranties 81...