Mainteance & Troubleshooting

29

Mainteance & Troubleshooting

The

CONTINUOUS DOVETAILER

will operate in good condition if a proper maintenance is made. Clean wood

chips, dust dirt or debris every day when job is finished.

Do not allow chips to accumulate inside of the machine. Always keep cutter sharp.

***If this machine is used in Quality Systems facility registered (ISO/QS 9001, TS16949, etc.), Please make

sure to document these Maintenance Protocols into Facilities Preventive Maintenance Standards and or

Operation Standards.***

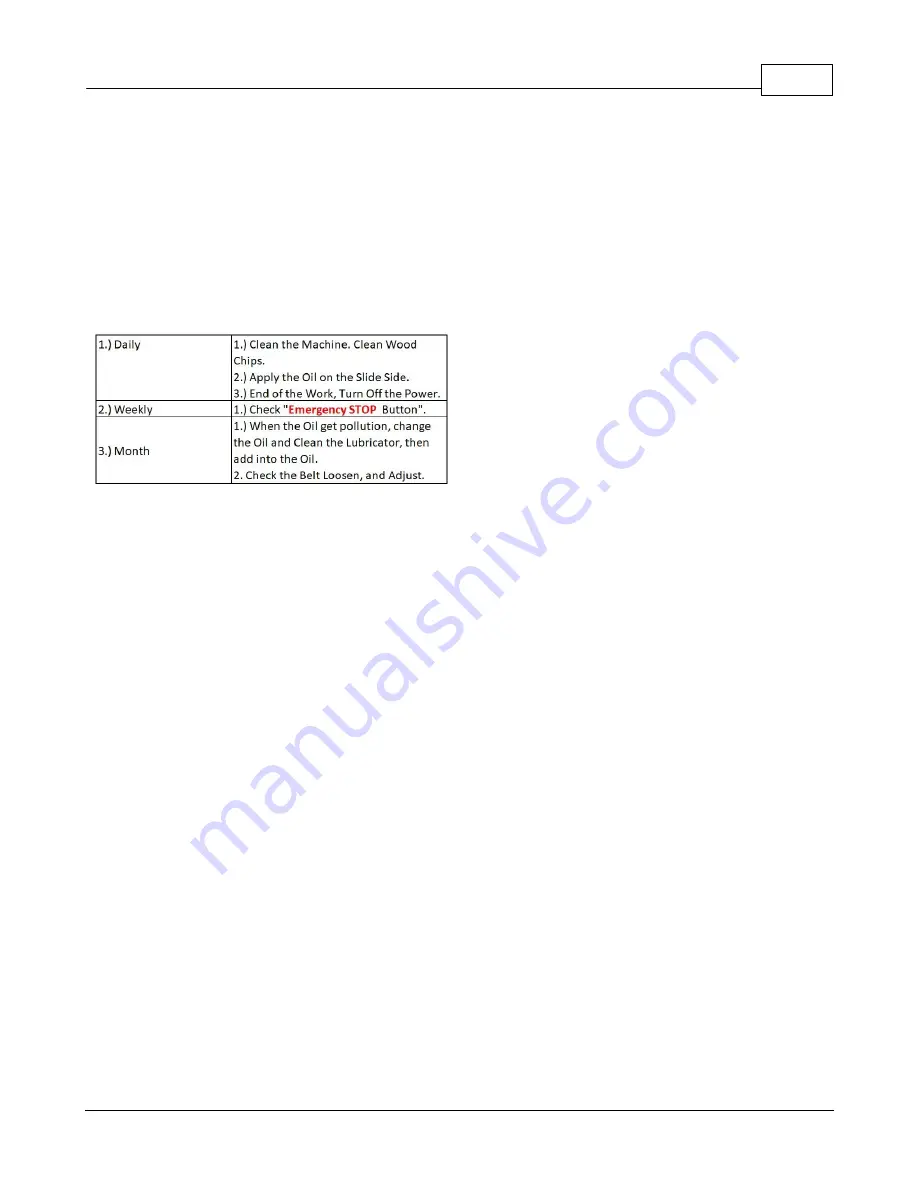

Maintenance Routine:

Summary of Contents for DT-18

Page 2: ......

Page 15: ...General Information 15 ...

Page 22: ...DT 18 DOVETAIL 22 Clamping Equipment YC 480 For straight boards Straight Curved Board ...

Page 23: ...Operation 23 ...

Page 26: ...DT 18 DOVETAIL 26 To adjust the height of spindle when you make different wood thickness ...

Page 27: ...Operation 27 Control Panel ...

Page 28: ...DT 18 DOVETAIL 28 ...

Page 34: ...DT 18 DOVETAIL 34 Diagrams Drawings Tenon ...

Page 35: ...Diagrams Drawings 35 Air Circuit Diagrams Parts List ...

Page 36: ...DT 18 DOVETAIL 36 Machine Parts YC 480 A YC 480B YC 480C YC 480A A ...

Page 37: ...Diagrams Drawings 37 YC 480A B YC 480A C ...

Page 38: ...DT 18 DOVETAIL 38 Parts Lists YC 480 A ...

Page 39: ...Diagrams Drawings 39 ...

Page 40: ...DT 18 DOVETAIL 40 ...

Page 41: ...Diagrams Drawings 41 ...

Page 42: ...DT 18 DOVETAIL 42 YC 480B ...

Page 43: ...Diagrams Drawings 43 ...

Page 44: ...DT 18 DOVETAIL 44 YC 480C ...

Page 45: ...Diagrams Drawings 45 ...

Page 46: ...DT 18 DOVETAIL 46 YC 480A A ...

Page 47: ...Diagrams Drawings 47 ...

Page 48: ...DT 18 DOVETAIL 48 YC 480A B ...

Page 49: ...Diagrams Drawings 49 YC 480A C ...

Page 50: ...DT 18 DOVETAIL 50 ...

Page 52: ...DT 18 DOVETAIL 52 ...

Page 56: ...DT 18 DOVETAIL 56 ...