Fusion F3 Table Saw - Troubleshooting -

47

© 2020 Laguna Tools

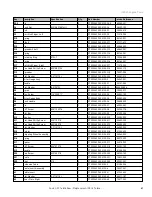

Troubleshooting

Behavior

Possible Causes

Solutions

Machine will not start

or continues to trip the

breaker.

1. Start capacitor at fault.

2. Motor connection wired wrong.

3. Wiring at fault.

4. Motor Start/Stop switch at fault.

5. Motor at fault.

6. Run capacitor at fault.

7. Wall circuit breaker tripped or at fault.

8. Power supply switched OFF or at fault.

9. Plug/receptacle at fault or wired incorrectly.

1. Test/replace if faulty.

2. Correct motor wiring connections.

3. Check/fix broken, disconnected, or corroded

wires.

4. Replace switch.

5. Test/repair/replace.

6. Test/replace if faulty.

7. Ensure circuit size is correct/replace weak

breaker.

8. Ensure power supply is on/has correct

voltage.

9. Test wires and contacts; correct the wiring.

Machine is

excessively loud or is

experiencing

excessive vibration.

1. Motor or component loose.

2. Blade at fault.

3. Motor mount loose/broken.

4. Machine incorrectly mounted.

5. Arbor pulley loose.

6. Belts worn or loose.

7. Pulley loose or at fault.

8. Arbor bearings at fault.

1. Inspect/replace damaged bolts/nuts, and re

tighten with thread-locking fluid.

2. Replace warped/bent blade; re-sharpen dull

blade.

3. Tighten/replace.

4. Tighten mounting bolts; relocate/shim

machine.

5. Re-tighten/replace arbor pulley.

6. Adjust tension of/replace belt.

7. Realign/replace shaft, pulley, setscrew, and

key.

8a. Replace arbor housing bearings; replace

arbor.

8b. Test by rotating shaft; grinding/loose shaft

requires bearing replacement.

Machine trips the

overload, or feels

underpowered during

operation.

1. Feed rate/cutting speed too fast.

2. Workpiece material unsuitable for machine.

3. Pulley/sprocket slipping on shaft.

4. Motor bearings at fault.

5. Contactor (internal breaker) at fault.

6. Motor overheated.

7. Workpiece crooked; fence not aligned.

8. Machine undersized for task; wrong blade.

9. Run capacitor at fault.

10. Belt is slipping from pulley.

11. Motor wired incorrectly.

12. Plug/receptacle at fault.

13. Motor at fault.

1. Decrease feed rate/cutting speed.

2. Only cut wood; ensure moisture is below

20%.

3. Test for good contacts/correct wiring.

4. Replace loose pulley/shaft.

5. Test/repair/replace.

6. Test all legs for power/replace if faulty.

7. Clean motor, let cool, and reduce workload.

8. Straighten or replace workpiece; adjust

fence.

9. Use correct blade; reduce feed rate or depth

of cut.

10. Test/repair/replace.

11. Adjust tension of/replace belt.

12. Wire motor correctly.

Summary of Contents for Fusion F3

Page 1: ...PRECISION WOODWORKING MANUAL Fusion F3 Table Saw MTSF3362203 0130 36 MTSF3362203 0130 52...

Page 21: ...Fusion F3 Table Saw Setup 21 2020 Laguna Tools Setup...

Page 54: ...Fusion F3 Table Saw Wiring Diagram 54 2020 Laguna Tools Wiring Diagram...

Page 56: ...Fusion F3 Table Saw Replacement Parts Diagram 56 2020 Laguna Tools Internal...

Page 57: ...Fusion F3 Table Saw Replacement Parts Diagram 57 2020 Laguna Tools Blade Guard Mitre Gauge...

Page 58: ...Fusion F3 Table Saw Replacement Parts Diagram 58 2020 Laguna Tools 36 Rails Fence...

Page 59: ...Fusion F3 Table Saw Replacement Parts Diagram 59 2020 Laguna Tools 52 Rails Fence...