-11-

www.igmtools.com

• Note on the Riving Knife

Since Riving Knife, other than those offered by

Laguna, has not been tested with this product,

use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only

Laguna, recommended accessories should be

used with this product.

•

Note on the saw blade

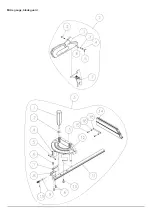

Installing/removing the riving knife

1. Unplug the tablesaw!

2. Make sure the lock is in open position

3. Insert the blade guard

4. Position the guard insert

5. Lock the blade guard

6. Reinstall throat plate

CAUTION: Make sure the blade guard is in line

with the blade. If it is not in line, please see the

Adjustment section.

3. Insert the blade guard

WARNING: MAKE SURE SAW IS

UNPLUGGED.

With the throat plate removed, and the cam lock

mechanism in the open position (pulled up),

insert the blade guard insert into the slot.

4. Position to the left of the casing

Make sure the guard is positioned correctly and

seated in the bottom of the casing. Grasp the

pawls with one hand, leaving the other hand

free to activate the cam action lock.

5. Lock the blade guard

Keep firm hold of the blade guard with left hand

and engage the cam lock with the thumb of

your right hand.

6. Reinstall the throat plate

Grasp the pawls up and out of the way to re-

insert the throat plate. Lock the throat plate.

CAUTION: Make sure the riving knife is in-line

with the blade. If it is not in line, please see the

Adjustments Section.

6.7 Installing/removing the Blade

1. Unplug the table saw!

2. Remove any blade guards, riving knifes, and

the throat plate to access the blade.

3. Set the arbor tilt to 0 degrees and lock.

4. Raise saw to highest position.

5. Engage blade lock (red component).

6. Remove the arbor nut and flange with arbor

wrench.

7. Remove or install blade.

CAUTION: Make sure the teeth of the blade are

facing the front of the saw as shown.

2. Remove all accessories

WARNING: MAKE SURE SAW IS

UNPLUGGED. To access the blade remove all

accessories around the blade, including riving

knifes, throat plates, ect.

3. Set arbor tilt to 0 and lock.

Set the arbor tilt to 0 degrees and lock the arbor

to prevent it from moving when installing or

removing blades.

4. Raise saw blade to highest position

5. Engage the blade lock

6. Remove arbor nut and flange

Limit position of the top guard

Use riving knife only with 250 mm

diameter blade

Riving knife thickness 2,3 mm

Only use this riving knife with 2 mm

and 3 mm teeth thickness

No saw blade should be used where

the maximum marked speed is lower

than the selected rotational speed of

the saw spindle.

5500 max rpm

Summary of Contents for Fusion2 2022

Page 2: ...2 www igmtools com...

Page 3: ...3 www igmtools com...

Page 18: ...18 www igmtools com Wiring Diagram Fusion 2 230V...

Page 19: ...19 www igmtools com Fence assembly...

Page 20: ...20 www igmtools com Mitre gauge blade guard...

Page 21: ...21 www igmtools com Motor and trunnion...

Page 22: ...22 www igmtools com Cabinet...