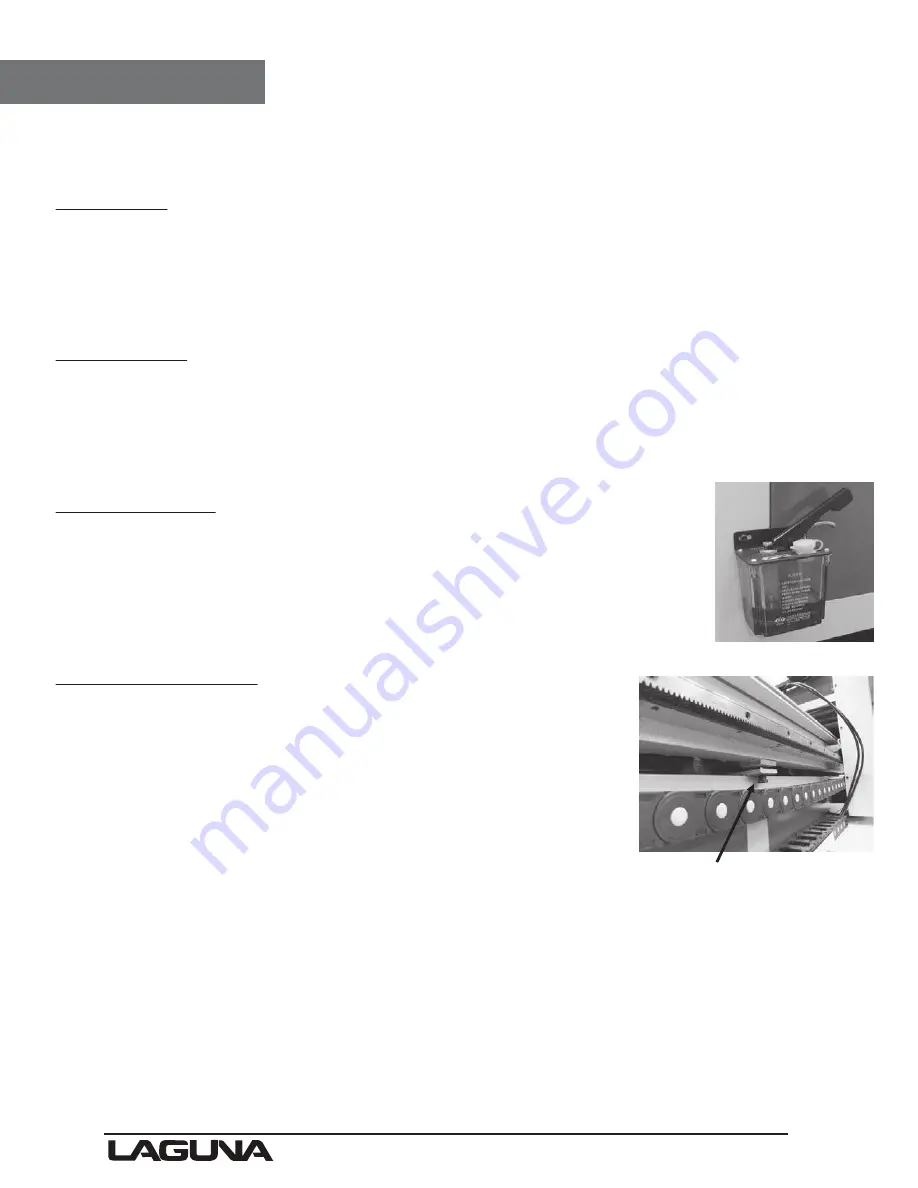

Central oiler

Table jacking point

26

Maintenance

As with any machine, to ensure optimal performance you must conduct regular maintenance.

Daily Checks

1.

Clean the machine and lubricate unpainted surfaces with a Teflon lubricant.

Wipe off any excess and buff with a dry polishing cloth. This will reduce the

likelihood of rust forming.

2.

Check cutter teeth for chips and dullness.

3.

Generally inspect the machine for damage and loose or worn parts.

Weekly Checks

1.

Clean the cutters.

2.

Check cutter teeth for chips and dullness.

3.

Generally inspect the machine for damage and loose or worn parts.

4.

Check the dust extraction for blockages and any large bits that could cause

blockages.

Oiling the Machine

The machine is provided with a central oiler. Do not over lubricate the machine

as excess oil attracts dirt and sawdust.

It is recommended that one pump of the oiler once a month will be sufficient

to keep your machine lubricated. When the oil tank needs filling, top up with

a good quality SAE 30 weight oil.

Jacking the Table Level

The machine is provided with table jacking points. The jacking

points come factory set and should not need adjustment. Do not

adjust the jacking points until you have contacted Laguna Tools, Inc.

customer service.

Summary of Contents for Laguna Series

Page 2: ......