-13-

www.igmtools.com

Inventory

Key

Name

Description

2.1

Stationary Wheels

Can be mounted on left or right stand

leg. Must be positioned so that the

machine is off the floor when the foot

pedal is engaged.

2.2

Foot Pedal Assembly

Must be positioned so that the

machine is off the floor when the foot

pedal is engaged.

2.3

Support Plate

Mounts to the (inside) stand leg with

foot pedal assembly (2.2).

2.4

Foot Pedal Caster

Mounts to foot pedal assembly (2.2).

2.5

Lathe Bolts and

Washers

Used to fasten the wheels to the

machine base.

2.6

Foot Pedal Spring

Installs in between the caster (2.4)

and the assembly (2.2).

3

Swivel Axle

Axle that spring (2.6) and caster (2.4)

are installed to.

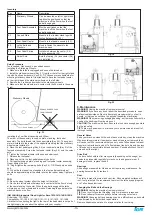

Setup Procedure

Tools needed: Hex wrench, open ended wrench

Installing the Stationary Wheels

1. Make sure the lathe is unplugged and cannot be turned on.

2. Install the stationary wheels (Key 2.1) to either the left or the right stand

leg with 2 bolts and washers (Key 2.5). TIP Choose more suitable side for

mounting stationary wheels. It is often best to have the foot pedal caster

on the right side and the stationary wheels on the left side.

3. Remove the 2 rubber pads closest to the stationary wheels.

4. Make sure that the wheels are in contact with the floor and in the same

height.

Fig. 33

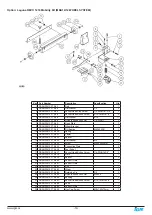

Installing the Foot Pedal Assembly and Wheel

The order of the assembly is: support plate, stand leg, foot pedal

assembly. The bolts thread into the support plate (Key 2.3). The support

plate is installed to the inside of the opposite stand leg that the stationary

wheels were installed to.

5. Place the foot pedal spring (Key 2.6) on the swivel axle (Key 3) of the

foot pedal assembly. Screw the foot pedal caster (Key 2.4) onto the swivel

axle.

6. Tighten the foot pedal caster with open ended wrench.

7. Release the foot pedal.

8. Place one bolt in the foot pedal assembly bolt slot.

9. Put together support plate, stand leg and foot pedal caster assembly.

Finger tighten the bolt.

10. Finger tighten the remaining bolts (Key 2.5). TIP We supply an extra

bolt.

11. When the foot pedal is not engaged, the foot pedal caster wheel

should be approximately at the same level as the rubber pads. Tighten all

bolts.

FAQ

Q: Does the wheel system affect the height of the lathe?

A: No, the two left wheels will always be in contact with the floor but only

at the same level as the caster. When the pedal is engaged the lathe

will prop up on the 3 wheels and is mobile. Releasing the pedal puts the

machine back on the floor.

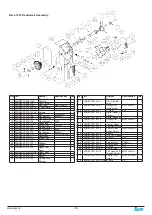

IGM LAGUNA Industrial Flood Light for Revo1836-1412-14BX-18BX

Order code: 151-1836L

Compatibility: 151-1836, 151-18BX, 151-1216, 151-1412, 151-14BX

L-bracket for connecting the light to the rear of the headstock is not part of

the light supply, inquire about the options with your supplier:

Fig. 34

Fig. 35

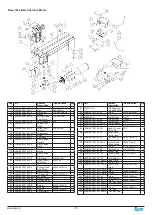

9. Maintenance

WARNING!

Unplug the machine from power source!

WARNING!

If you have any doubt about the described procedure, seek

professional assistance. Do not attempt any procedure that you feel is

unsafe, or that you do not have the physical capability of achieving.

WARNING!

When removing packaging banding, extreme caution must be

used as the banding will spring when cut.

CAUTION!

The machine is heavy. Ensure that you have enough people to

do the job safely.

TIP

There may be sawdust in or around your new machine as a result of

thorough testing.

General Notes

Keep your machine clean At the end of each work day, clean the machine.

Wood contains moisture. If sawdust or wood chips are not removed they

will cause rust. We recommend that you only use a Teflon based lubricant.

Regular oil attracts dust and dirt. Teflon lubricant tends to dry and has less

of a tendency to accumulate dirt and saw dust. Periodically check that all

nuts and bolts are tight.

Drive Belt

The drive belt should last for many years (depending on the usage) but

needs to be inspected regularly for cracks, cuts and general wear. If

damage is found, replace the belt.

Bearings

All bearings are sealed for life and do not require any maintenance. If a

bearing becomes faulty, replace it.

Rust

The lathe is made from steel and cast iron. All non-painted surfaces will

rust if not protected. We recommend to protect the lathe by applying wax

or a Teflon based lubricant.

Changing the Belt and the Bearings

WARNING!

Unplug the machine from power source!

TIP

Do not over torque the threading, only firm pressure is required.

TIP

Do not attempt to remove pulleys before removing set screws.

WARNING!

Changing belt and bearings can be a difficult task and should

be performed by an authorized repair station.

Remove headstock and take it to a repair station for servicing.

Stationary Wheels

Same Spacing

REMOVE RUBBER PADS

FROM THE BASE