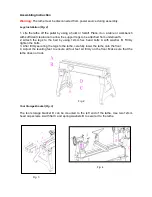

1, With an assistant, attach the extension bed to lathe bed right end with two head cap

bolts B. Slightly tighten the bolts. These two bolts must be taken off as soon as swing

away system assembly is completed (Fig.9)

2, Adjust the extension bed flush to the lathe bed. Make sure inside ways and surfaces are

aligned.

3, Slide the tailstock back to the position as show in figure. X=30mm or 1-

1/2” (Fig. 10)

4, Rotate the lock handle until the tailstock locked firmly. Now the extension bed is well

aligned with lathe bed (Fig. 11)

5, Put the two eccentric pivot pins in lathe bed, turn the pins until it slightly touch extension

bed bottom. Secure pivot pins with nuts D (Fig.9)

6, Mount the hinge between lathe bed and extension bed with head cap screws, spring

washers and flat washer (Fig.11).

Do not

tighten head cap screws at this moment. Use

alan wrench to tun the set screws until it hit beds. Then firmly tighten bolts.

7.,Mount clamping device on both lathe and extension bed as shown on Fig.12.

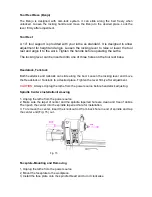

Operation of Lathe

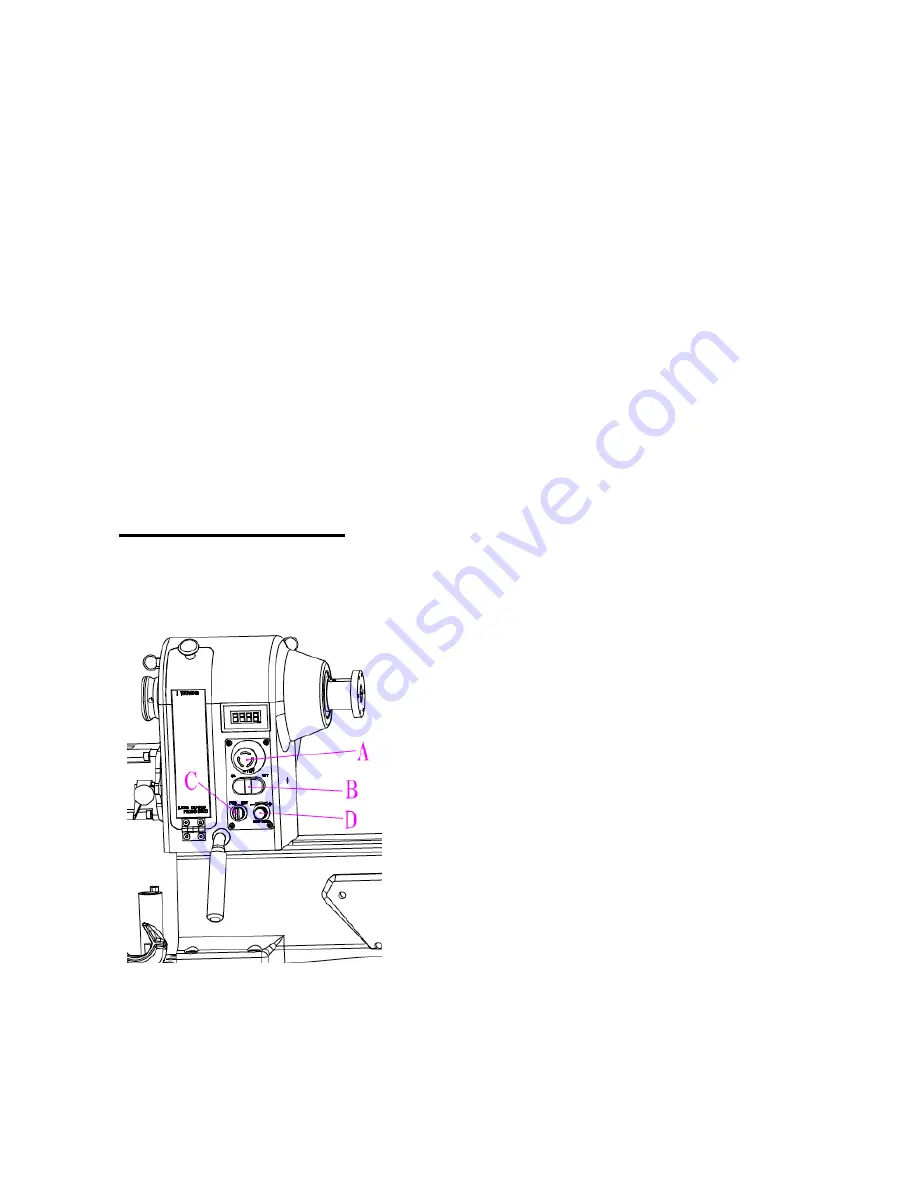

Control Panel Information (Fig. 13)

Fig. 13

A, Spindle speed readout: Indicates the

spindle speed in RPM.

B, On/Off Switch: Turns lathe ON and OFF

NOTE:

If a sudden power failure occurs,

the spindle will not re-start automatically

when the power is restored to the machine.

Push the off button

C

to reset the switch,

and then press the on button

D

to restart

the lathe.

C, Spindle direction switch: Toggles the

spindle direction between forward or

reverse.

Forward: Spindle rotates towards you;

Reverse: Spindle rotates away from you;

D, Speed control knob: Adjust the spindle

speed within the range.