30

PXl16 Sheartec:II Planer \ Maintenance

Adjustment of Pressure Bar

WARNING

·

TURN PLANER OFF AND DISCONNECT POWER BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS!

The pressure bar should be set even with the lowest point of knife. Make sure the knives are set properly

see the “Setting / Changing Knives” section prior to making any adjustments.

1. Disconnect machine from power source.

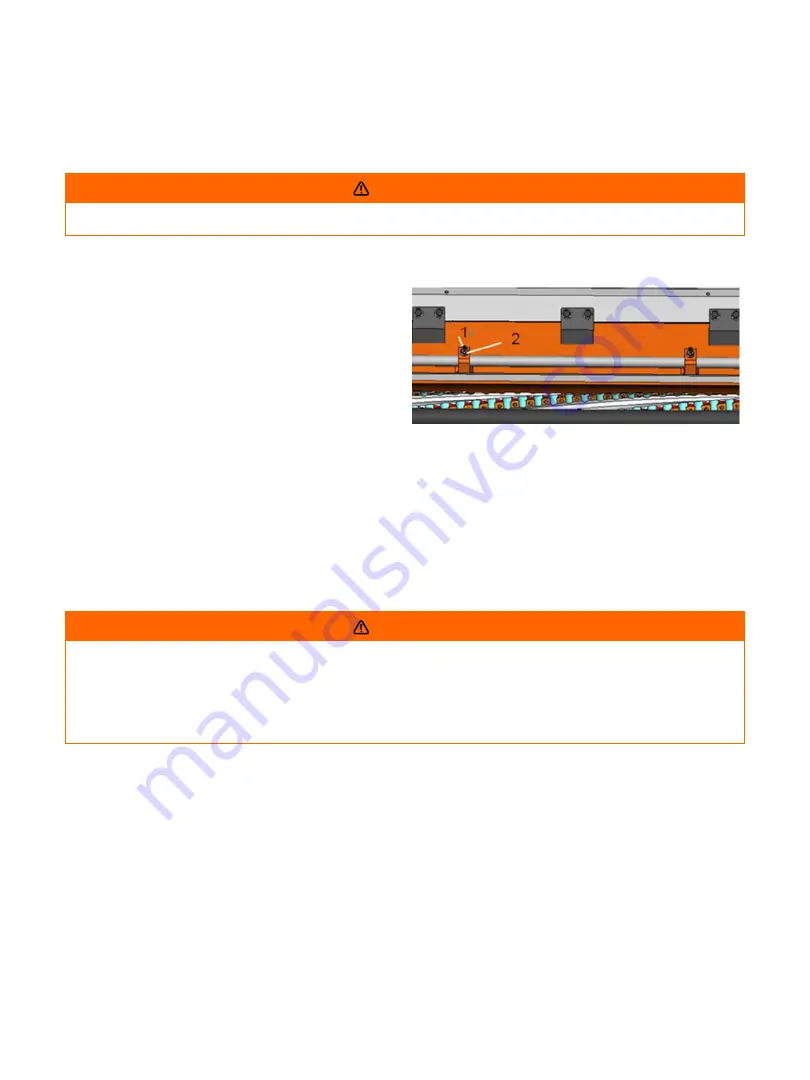

2. Loosen screw (Fig. 19, 1) and nut (Fig.19, 2) turn

the screw to the right so that the pressure bar

moves upward. Place gauge block and 0.2m/m

thickness gauge (Fig.17, A) under the

cutterhead.

3. Place gauge block under pressure bar.

4. Make pressure bar touch the top of the gauge

block.

5. Finally, tighten the screw and replace the nut.

FIG. 19: PRESSURE BAR ADJUSTMENT

Adjustment of Out-feed Roller

WARNING

·

TURN PLANER OFF AND DISCONNECT POWER BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS!

·

MAKE SURE ALL KNIFE INSERT SCREWS ARE TIGHTENED SECURELY. LOOSE INSERTS CAN BE PROPELLED AT HIGH

SPEED FROM A ROTATING CUTTERHEAD, CAUSING INJURY.

·

TORQUE EACH SCREW TO 52-60 IN/LBS.

·

KNIVES ARE EXTREMELY SHARP. BE VERY CAREFUL WHEN HANDLING KNIVES. FAILURE TO COMPLY MAY CAUSE

SERIOUS INJURY

The out-feed roller should be set 0.02” below the lowest point of knife. Make sure the knives are set

properly see the “Setting / Changing Knives” section prior to making any adjustments.

Summary of Contents for Sheartec:II PXl16

Page 1: ...PXl16 Sheartec II Planer Owner s Manual MPLANPX16 0130 3 10 2021...

Page 24: ...24 PXl16 Sheartec II Planer Setup Assembling FIGURES 10 12 DRO ADJUSTMENT...

Page 38: ...38 PXl16 Sheartec II Planer Replacement Parts Diagram Table Lift...

Page 39: ...39 PXl16 Sheartec II Planer Replacement Parts Diagram Stand Motor...