Doc#: 60-70-004

Revision: 07

Page 9

User’s Manual

USA: +1 888.246.9050 Europe: +44.1342.315044 Asia: +886.3.312.9292

www.lairdtech.com

•

clv.customerpos@lairdtech.com

6.

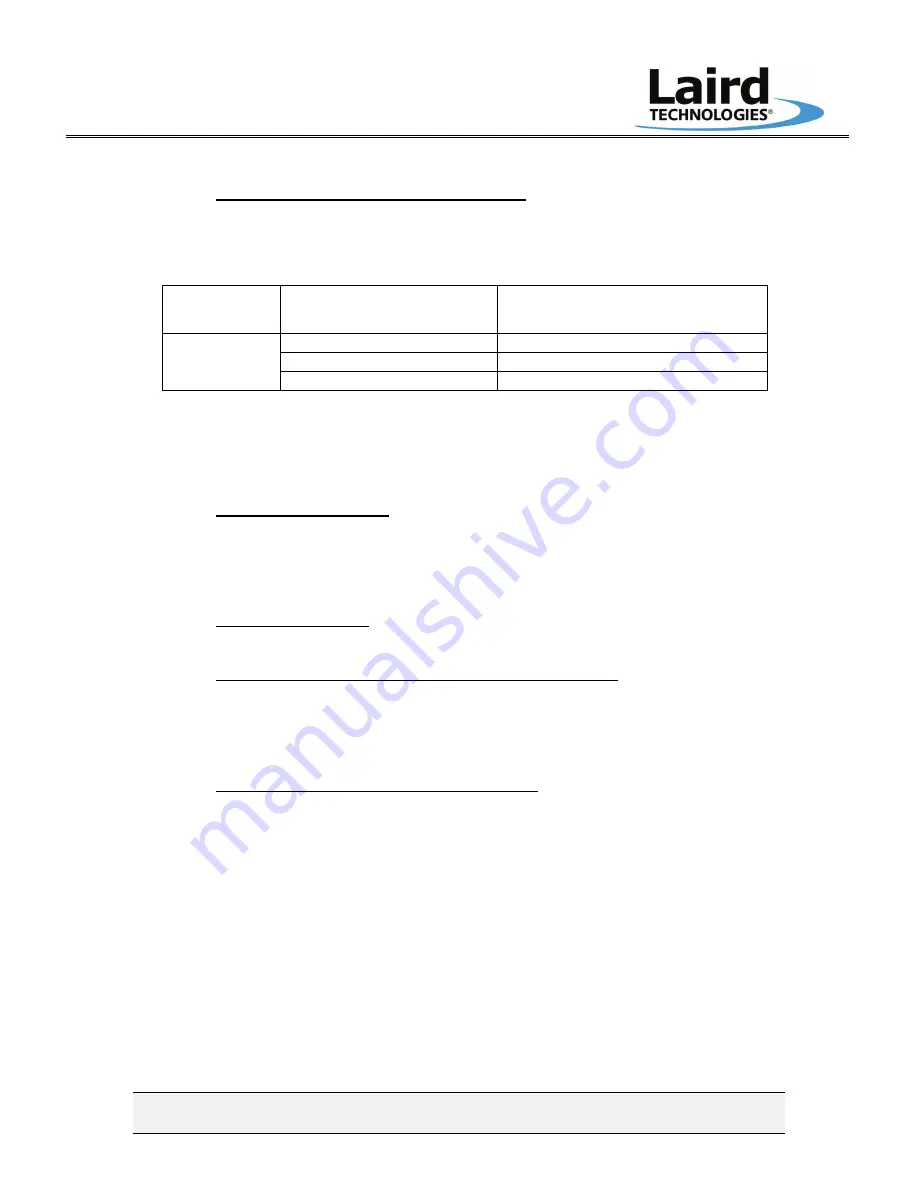

Recommended Fluid Couplings

For the fluid line connections, Laird Technologies recommends the following

male couplings.

Unit

Tubing Inner Diameter

CPC (Colder Products Co.)

Part Number

1/4”

PLCD26004

5/16”

PLCD26005

MRC 150,

MRC 300

3/8”

PLCD26006*

* A pair of the indicated couplings is included with each chiller unit.

For technical questions about these couplings, or to locate a distributor,

please visit CPC’s website, www.colder.com.

7.

Digital Controller

The controller is available with either RS232 or RS485 serial communication

and controls exiting fluid temperature to

±

0.16

°

C. A separate manual from

the controller manufacturer is included with each unit.

1.

To display set point Press and hold the

»

button. The display will now

show the temperature set point and alternately the units (

°

C or

°

F).

2.

To enter new set point (Factory preset at 10

°

C) Hold the

»

button

(displaying set temperature) while pressing either

f

or

g

to increase or

decrease the set point. While holding the

»

button, release

f

or

g

buttons

to display the new set point. Release the

»

button and the default display

(actual exiting fluid temperature) will reappear.

3.

To adjust other functions of the controller Press

f

and

g

together for 3

seconds.

f

or

g

will scroll through the functions available on that menu level

and pressing either

»

and

f

together or

»

and

g

together will change menu

levels. The following table gives some information concerning some of the

common operational functions of the controller. To change functions other

than those shown (recommended for advanced users only), please consult the

separate manual for the controller.