16

4. Initial Operation

4.1 Safety Indications Related to Initial Operation

CAUTION

Danger of malfunction caused by faulty connections during initial operation!

Before switching on the unit make sure that:

•

All safety equipment of the unit is implemented and functional.

•

All connections were properly made.

•

Nobody is endangered by the start-up of the unit.

•

Only cooling hoses with enough pressure resistance and with compatibility with used coolant is used!

•

Run cooling unit always with correct coolant level above cooling fins inside the heat exchanger

•

Read the manual before setting to work.

Moreover:

•

Never operate cooling unit when ball cock is closed, otherwise damage of pump may occur!

•

Never operate damaged or leaking equipment!

Please follow the rules in chapter Safety Regulations on page 9.

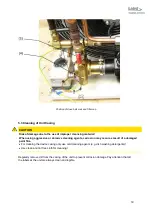

4.2 Setting to Work

4.2.1 Connecting the unit electrically

DANGER

Electrical danger!

Work on electrical installations may be carried out by trained and authorized electricians only.

Switch off the unit before starting your work.

Disconnect the unit from mains by pulling the mains plug.

Secure the unit against being switched on again.

Verify that the unit is disconnected.

Carry out earthing and short circuiting.

Keep unauthorized persons away from the working area.

NOTE

Risk of damage through improper connections!

Improper integration of the unit into the safety circuit of the device to be cooled will lead to

the inoperativeness of the safety equipment included in the unit.

Ensure that all connected safety equipment is properly functioning.

All tasks should be carried out only by expert staff.

4.2.2 Carrying out Setting-to-Work

•

The cooling unit must be positioned horizontally for sufficient air circulation without

blocking the air openings

•

Remove service cap