18

5. Maintenance and Cleaning

Diligent maintenance is the prime factor for assuring an error-free and efficient operation of

the unit. Operating personnel can perform these tasks when properly trained.

Regularly check the water level and refill water and antifreeze, if necessary.

5.1 Heat exchanger

In order to achieve maximum cooling capacity keep the heat exchanger of the cooling unit

clean. Regularly check it and if necessary clean it:

Proceed as following:

1. Disconnect cooling unit from the mains

2. Remove complete cover

3. Remove dust by forcing it out in the opposite direction from which it entered. If

compressed air is available, direct the air against the inside of the heat exchanger

4. Mount cover

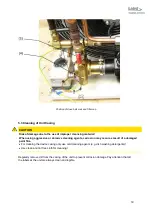

5.2 Pump

About every 3 months check the filter of the pump for clean condition, in case of polluted

water, more often.

CAUTION

Clean filter regularly according to maintenance instructions, otherwise damage of pump

may occur!

Proceed as following:

1. Disconnect cooling unit from the mains

2. Remove cover

3. Close ball cock

4. Unscrew filter cap (24 mm nut)

Note: Some water will run out of pump. Collect the water with suitable vessel!

5. Remove and clean filter if necessary or replace filter

6. Insert filter and mount cap

7. Open ball cock

CAUTION

Never operate cooling unit when ball cock is closed, otherwise damage of pump may

occur!

8. Mount cover

9. Run cooling unit to deaerate cooling circuit (Setting to work)

10. Check water level and refill if necessary