27

9. Maintenance and Cleaning

Diligent maintenance is the prime factor for assuring an error-free and efficient operation of the unit.

Operating personnel can perform these tasks when properly trained.

Maintenance Schedule

Device

Activity

Interval

Criteria

Tools

Performer

Heat Exchanger

Clean

Minimum weekly

(if required, daily)

Plate fins and

ventilation grids

not polluted

Slotted screw

driver 7 x 1 mm,

compressed air,

vacuum cleaner

Operating

personnel

Coolant container Check filling

Weekly

Coolant level well

above mesh

Visual inspection

Operating

personnel

Strainer

Clean,

replace if

required

Every 3 months,

more often when

coolant polluted

Strainer

undamaged and

clean

Metric AF24

wrench, cloth or

vessel

Operating

personnel

11. Maintenance schedule

Cleaning of Heat Exchanger

Cooling capacity is heavily reduced, if the heat exchanger is polluted. The heat exchanger must be

checked for pollution regularly and be cleaned if required.

For cleaning the heat exchanger follow these steps:

4)

Disconnect the unit from mains.

6)

Remove the side panel and the unit cover.

7)

Clean the heat exchanger using compressed air opposite to the direction of air entrance into

the unit (i.e. from the inside out). Be careful in order not to damage the plate fins.

8)

Remove any pollution from the ventilation grid and the side panel using a vacuum cleaner.

9)

Remount the unit cover and the side panel.

The unit is ready for operation.

Refilling of Coolant

Since the cooling circuit is an open circuit, evaporation of coolant may occur. Thus, the filling level of

the coolant container must be checked regularly and coolant might have to be refilled as described on

page 22.

Summary of Contents for WL3004

Page 1: ...WL3004 Liquid to Air Cooling System Specification and User Manual Version 1 2 ...

Page 35: ...35 Addendum Flow scheme ...

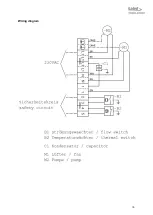

Page 36: ...36 Wiring diagram ...

Page 37: ...37 ...