Lake Shore Model 321 Autotuning Temperature Controller User’s Manual

Installation

2-5

Some loss in accuracy can be expected since the voltage measured at the voltmeter becomes

the sum of the sensor voltage and the voltage drop across the connecting leads. The exact

measurement error will depend on sensor sensitivity and variations resulting from changing

temperature. For example, a 10

Ω

lead resistance will result in a 0.1 mV voltage error. The

resultant temperature error at liquid helium temperature is only 3 mK, but, because of the

diode’s lower sensitivity (dV/dT) at higher temperatures, it becomes 10 mK at liquid nitrogen

temperature.

2. Four-Lead

Measurements

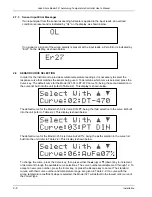

All sensors, including both two-lead and four-lead devices, can be measured in a four-lead

configuration to eliminate the effects of lead resistance. The exact point at which the connecting

leads are soldered to the two-lead sensor normally results in a negligible temperature

uncertainty.

I+

V+

I–

V–

Four-Lead

Diode

Four-Lead

Platinum

I+

V+

I–

V–

The four-lead measurement configuration should always be used with Series PT-100 Platinum

Sensors being attached to the Model 321-02.

2.7.1.2

Connecting Leads To The Sensor

An excessive heat flow through the connecting leads to any temperature sensor can create a

situation where the active sensing element is at a different temperature than the sample to which

the sensor is mounted. This is then reflected as a real temperature offset between what is

measured and the true sample temperature. Such temperature errors can be eliminated by proper

selection and installation of the connecting leads.

In order to minimize any heat flow through the leads, the leads should be of small diameter and low

thermal conductivity. Phosphor-bronze or Manganin wire is commonly used in sizes 32 or 36 AWG.

These wires have a fairly low thermal conductivity yet the electrical resistivities are not so large as

to create any problems in measurements.

Lead wires should also be thermally anchored at several temperatures between room temperature

and cryogenic temperatures to guarantee that heat is not being conducted through the leads to the

sensor.

2.7.1.3 Sensor

Mounting

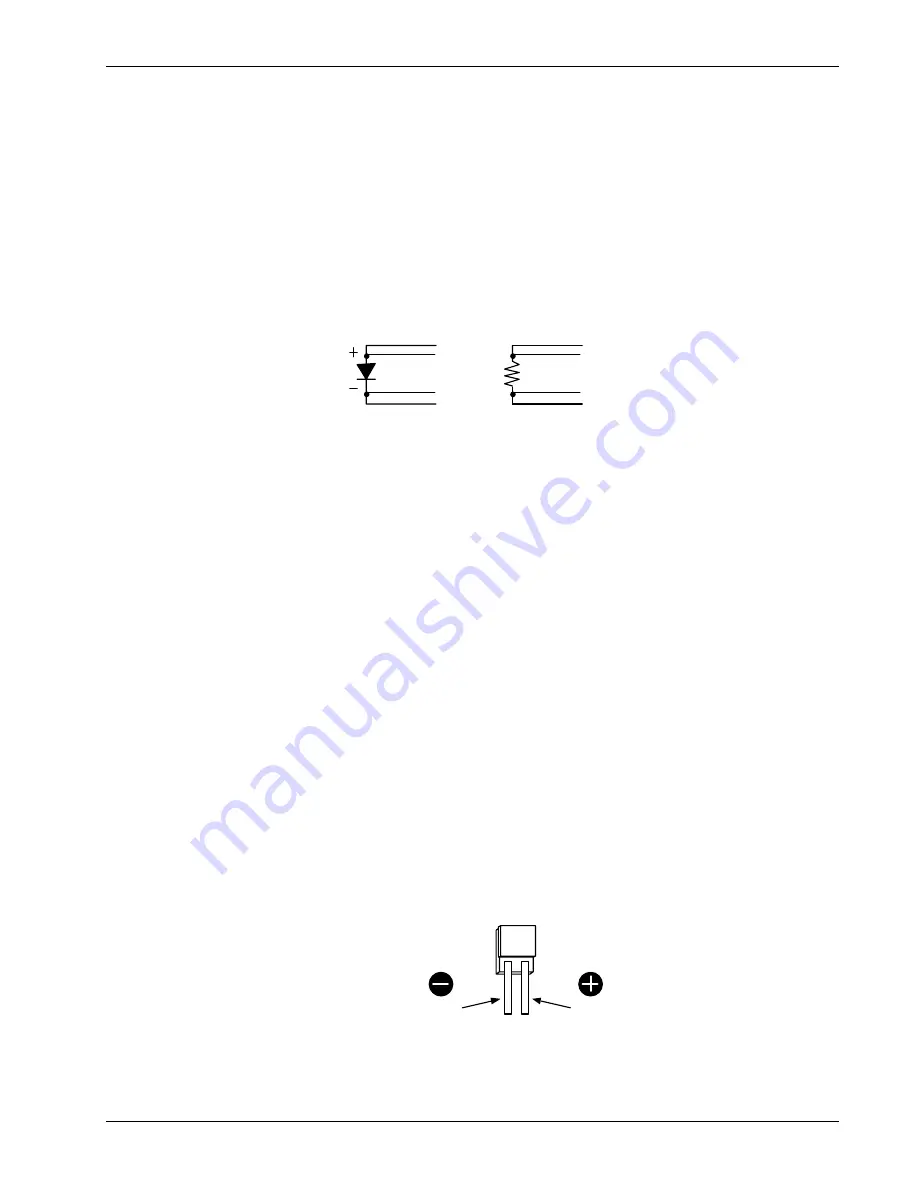

Before installing a diode sensor, identify which lead is the anode and which is the cathode. When

viewed with the base down and with the leads towards the observer, the positive lead (anode) is on

the right and the negative lead (cathode) is on the left. The Lake Shore DT-470-SD silicon diode

sensor lead configuration is shown below. For other sensors, read the accompanying literature or

consult the manufacturer to ensure positive identification of sensor leads. Be sure the lead

identification remains clear even after installation of the sensor. It is also a good idea to record the

serial number and location of the sensor.

DT-470-SD

Diode Sensor Leads

Anode

Cathode