Lake Shore Model 321 Autotuning Temperature Controller User’s Manual

Operation

3-7

SoftCal can be implemented in one of two ways: as a method or a service.

1. The Customer may perform the SoftCal procedure. This would involve using the Model 321 and

the silicon diode sensor to sense either two or three sources of a stable temperature. For a 3

point SoftCal, the Customer must provide stable temperatures of 4.2 K (Liquid Helium), 77.35 K

(Liquid Nitrogen), and 295 K (Room Temperature). For a 2 point SoftCal, the Customer must

provide stable temperatures of 77.35 K and 295 K. The procedure to follow is provided in

Paragraph 3.2.6.2. User performed SoftCal has the advantage of nulling both sensor and

controller inaccuracies.

2. Lake Shore provides an inexpensive SoftCal Calibration Service. This service will provide the

Customer with the voltages corresponding to the 2 or 3 point calibrations. The calibration consists

of a modified (T vs. V) Curve 10 Table for a specific DT-400 Series Sensor. A SoftCal Report is

generated that includes the voltages for data points and a unique sensor curve table interpolated

from these 2 or 3 points. The procedure for entering these voltages is provided in Paragraph

3.2.6.3.

Using either method, the Model 321 will create a new curve for this specific diode, which is stored as

Curve 12 in the controller memory. This procedure can make an inexpensive Band 13 diode more

accurate than our tightest Band 11 diode (but, of course, with the interchangeability).

3.2.6.1 SoftCal

Errors

The calibration cannot be transferred from one sensor to another. A SoftCal calibration will

compensate for some of the temperature error of the controller if an instrument is used to do the

calibration. If the sensor is calibrated outside the instrument, the specified accuracy of the

instrument must be added to the sensor accuracy.

SoftCal accuracy also depends on the precision of the setting points. An error in the setting

temperature can actually degrade the sensor performance beyond the normal tolerance bands. For

example, the boiling point of nitrogen at standard pressure is near 77.4 K. During a storm, this can

change as much as 0.2 K because of the change in atmospheric pressure. These types of errors

must be added to the sensor accuracy specification.

3.2.6.2

Customer Performed SoftCal

The Customer may locally perform the SoftCal procedure using their own controller and silicon

diode sensor. Although not as convenient as obtaining a Lake Shore SoftCal Report, it has the

advantage of nulling the error of both the sensor and the controller as a system, thereby eliminating

much of the controller error. Depending on the temperature range of interest, the Customer has

the option of doing a 2 point or 3 point SoftCal. This example will assume a 3 point SoftCal. If only

2 points are required, then omit the steps associated with reading the voltage at 4.2 K.

Requirements are a stable temperature source at three temperatures: 4.2 K (Liquid Helium),

77.35 K (Liquid Nitrogen), and <300 K (room temperature). It does not matter in which order

the SoftCal data are taken.

NOTE:

Allow the instrument to warm up for

≈

1 hour before beginning the SoftCal procedure.

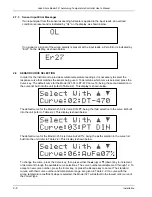

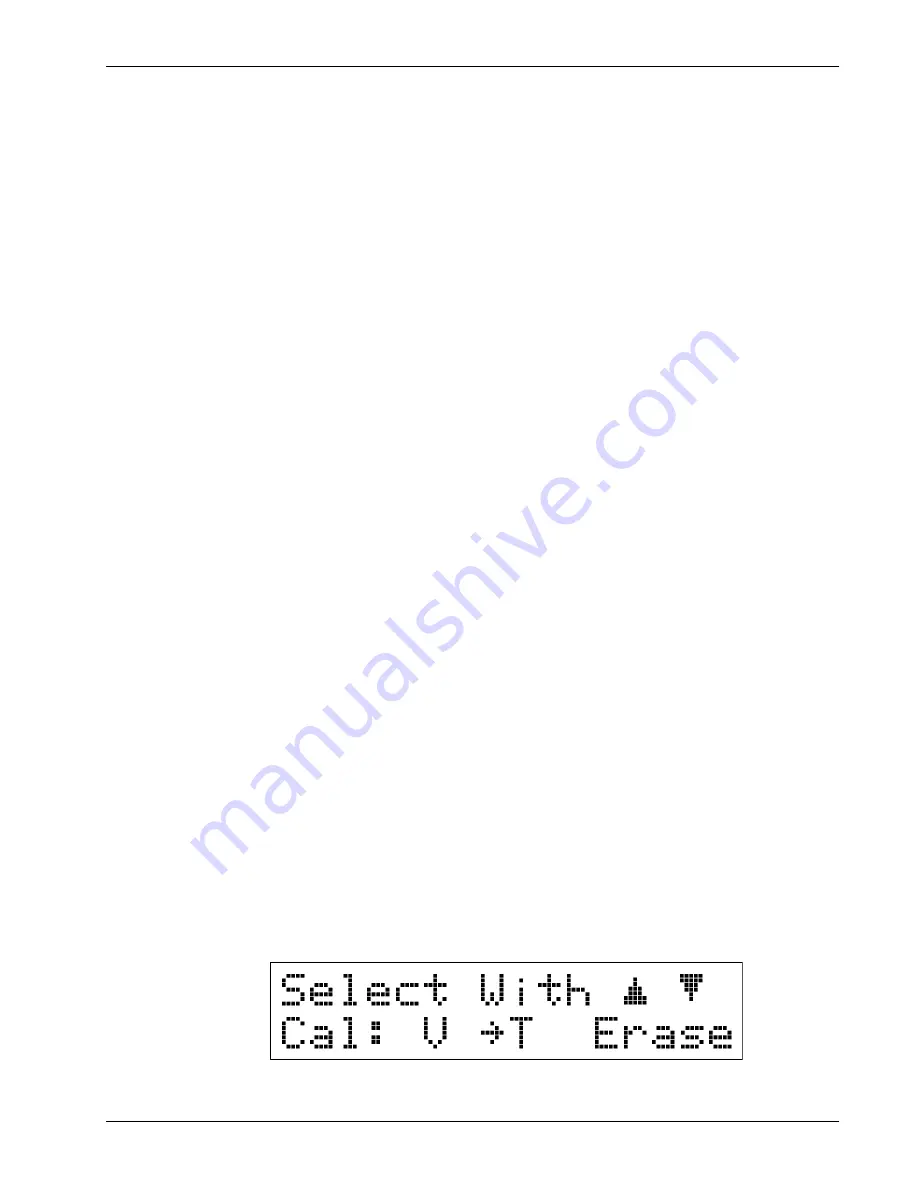

In this example, we will take our first SoftCal measurement around 4.2 K. Immerse the temperature

sensor in Liquid Helium and allow the controller temperature reading to stabilize. Press the

SoftCal

button. Use either the

s

,

t

, or

SoftCal

button to cycle the selector arrow (

→

) to T (Temperature).

You will see the following display.