Lake Shore Model 331 Temperature Controller User’s Manual

2.3.5 Contact

Pressure

When sensors are permanently mounted, the solder or epoxy used to hold the sensor act as both

gasket and adhesive. Permanent mounting is not a good solution for everyone because it limits

flexibility and can potentially damage sensors. Much care should be taken not to over heat or

mechanically stress sensor packages. Less permanent mountings require some pressure to hold the

sensor to its mounting surface. Pressure greatly improves the action of gasket material to increase

thermal conductivity and reduce thermal gradients. A spring clamp is recommended so that different

rates of thermal expansion do not increase or decrease pressure with temperature change.

2.3.6 Lead

Wire

Different types of sensors come with different types and lengths of electrical leads. In general a

significant length of lead wire must be added to the sensor for proper heat sinking and connecting to

a bulk head connector at the vacuum boundary. The lead wire must be a good electrical conductor,

but should not be a good

thermal

conductor, or heat will transfer down the leads and change the

temperature reading of the sensor. Small 30 to 40 AWG wire made of an alloy like phosphor bronze is

much better than copper wire. Thin wire insulation is preferred and twisted wire should be used to

reduce the effect of RF noise if it is present. The wire used on the room temperature side of the

vacuum boundary is not critical so copper cable is normally used.

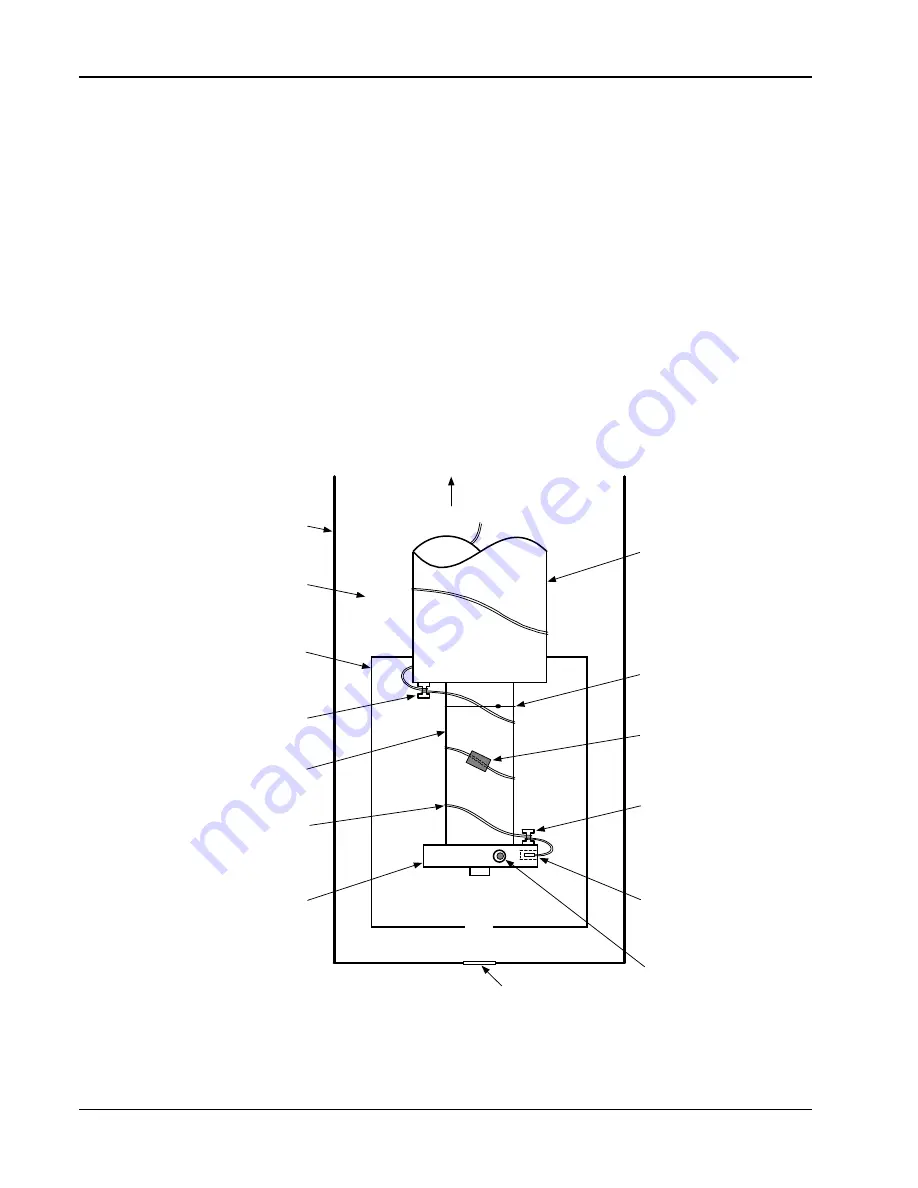

Drawing

Not To Scale

To Room

Temperature

Refrigerator

Expander

Refrigerator

Second

Stage

Dental

Floss

Tie-Down

Thermal

Anchor

(Bobbin)

Thermal

Anchor

(Bobbin)

Radiation Shield

Sensor

Cold Stage and

Sample Holder

Optical Window

(If Required)

Cryogenic Tape

Cryogenic Wire

(small

diameter,

large AWG)

-or-

Vacuum Shroud

Vacuum Space

Heater

(wiring not shown

for clarity)

P-331-2-2.bmp

Figure 2-2. Typical Sensor Installation In A Mechanical Refrigerator

2-6

Cooling System Design