Lake Shore Model 331 Temperature Controller User’s Manual

2.4.2 Heater

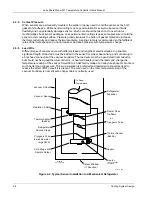

Location

For best temperature measurement accuracy the heater should be located so that heat flow between

the cooling power and heater is minimized. For best control the heater should be in close thermal

contact with the cooling power. Geometry of the load can make one or both of these difficult to

achieve. That is why there are several heater shapes and sizes.

2.4.3 Heater

Types

Resistive wire like nichrome is the most flexible type of heater available. The wire can be purchased

with electrical insulation and has a predictable resistance per given length. This type of heater wire

can be wrapped around a cooling load to give balanced, even heating of the area. Similar to sensor

lead wire, the entire length of the heater wire should be in good thermal contact with the load to allow

for thermal transfer. Heat sinking also protects the wire from over heating and burning out.

Resistive heater wire is also wound into cartridge heaters. Cartridge heaters are more convenient but

are bulky and more difficult to place on small loads. A typical cartridge is 1/4 inch in diameter and

1 inch long. The cartridge should be snugly held in a hole in the load or clamped to a flat surface.

Heat sinking for good thermal contact is again important.

Foil heaters are thin layers of resistive material adhered to, or screened on to, electrically insulating

sheets. There are a variety of shapes and sizes. The proper size heater can evenly heat a flat surface

or around a round load. The entire active area should be in good thermal contact with the load, not

only for maximum heating effect, but to keep spots in the heater from over heating and burning out.

2.4.4 Heater

Wiring

When wiring inside a vacuum shroud, we recommend using 30 AWG copper wire for heater leads.

Too much heat can leak in when larger wire is used. Heat sinking, similar to that used for the sensor

leads, should be included so that any heat leaking in does not warm the load when the heater is not

running. The lead wires should be twisted to minimize noise coupling between the heater and other

leads in the system. When wiring outside the vacuum shroud, larger gage copper cable can be used,

and twisting is still recommended.

2.5

CONSIDERATION FOR GOOD CONTROL

Most of the techniques discussed above to improve cryogenic temperature accuracy apply to control

as well. There is an obvious exception in sensor location. A compromise is suggested below in

Paragraph 2.5.3 – Two Sensor Approach.

2.5.1 Thermal

Conductivity

Good thermal conductivity is important in any part of a cryogenic system that is intended to be at the

same temperature. Most systems begin with materials that have good conductivity themselves, but as

sensors, heaters, sample holders, etc., are added to an ever more crowded space, the junctions

between parts are often overlooked. In order for control to work well, junctions between the elements

of the control loop must be in close thermal contact and have good thermal conductivity. Gasket

materials should always be used along with reasonable pressure.

2.5.2 Thermal

Lag

Poor thermal conductivity causes thermal gradients that reduce accuracy and also cause thermal lag

that make it difficult for controllers to do their job. Thermal lag is the time it takes for a change in

heating or cooling power to propagate through the load and get to the feedback sensor. Because the

feedback sensor is the only thing that lets the controller know what is happening in the system, slow

information to the sensor slows the response time. For example, if the temperature at the load drops

slightly below the setpoint, the controller gradually increases heating power. If the feedback

information is slow, the controller puts too much heat into the system before it is told to reduce heat.

The excess heat causes a temperature overshoot, which degrades control stability. The best way to

improve thermal lag is to pay close attention to thermal conductivity both in the parts used and their

junctions.

2-8

Cooling System Design