O & M Manual – Insulated Case ATS Rev: October 2020

Publication Number:

MN0100700E

Version: V10.01.20

Page 50

5.

Operating Mechanism

5.1.

General Information

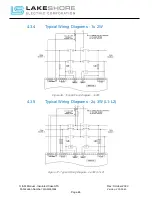

The operating mechanism pictured in Figure 39 - Gear Motor Assembly (page 51), is used in

single motor operated, and dual motor operated transfer switches. The motor (4) is a universal

type, reversible motor and is shipped as a complete component including the gearbox and motor

control board. The gearbox is a sealed unit, which should never require maintenance or attention.

Because of the wide range of molded case switches used on Lake Shore Electric Transfer

Switches, if motor replacement is necessary, please specify the serial number and model number

of the transfer switch.

5.2.

Operation

When a signal to transfer is received from the LSE8600 Controller, the motor is energized, and

the gear box turns the drive drum (8) which sets up a friction pull between itself and the drive shoe

lining (13). This friction pull is enough to pull the drive arms (2) over to the new position, actuating

the switch toggle. As soon as the drive arms have reached their new position, the auxiliary switch

changes position signaling the controller to cut off the motor, while at the same time, setting up

the circuit for the next transfer in the opposite direction. Because of the built-in features of the

friction drive, it is possible to manually operate the switch by moving the manual handle (1) without

engaging any clutches or devices.

5.3.

Required Maintenance

Please refer to the Appendix A, Appendix B and Appendix C for required maintenance on the

operating mechanism necessary to maintain your exclusive one-year Lake Shore Electric

Corporation warranty.

5.4.

Motor Assembly

To assemble the operating mechanism, first place the drive drum keys (11) on each side of the

shaft, which extends from the gearbox. Next, slide the two drive drums (8) on the shafts. Insert

one drive shoe pivot (10) into one drive arm (2) from the bottom, followed by the drive shoe (12)

and the drive shoe lining (13). Be sure that the lining fits snugly into the drive shoe and that the

concave cup end of the drive shoe pivot (10) engages the nipple on the drive shoe. Hold the entire

assembly together and slip it onto one shaft, pushing it all the way to the drive drum. Now the

spring (9) and adjustment screw (3) may be assembled into the drive arm (2) from the top. Repeat

this procedure for the other drive arm assembly if present.