O & M Manual – Insulated Case ATS Rev: October 2020

Publication Number:

MN0100700E

Version: V10.01.20

Page 10

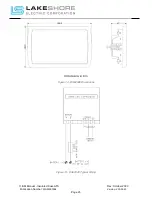

2.2.

Dual Motor Operator

The Dual Motor Automatic Transfer Switch (ATS) operates in much the same way as described

in section 2.1 Single Motor Operator with the exception that each molded case unit has its own

motor operator. This allows the load to be disconnected from both the S1 and S2 power sources,

offering the load a "Neutral / Off" position. When the LSE8600 sends the signal to transfer, one

motor operator disconnects its source, which transfers the switch to the open position temporarily.

Then, the LSE8600 sends the signal to the opposite motor operator, connecting the load to its

source.

All phases of the preferred power source, S1 (typical: Utility), are continuously monitored by the

voltage sensing inputs of the LSE8600 Controller. These undervoltage settings are preset to 90%

pick-up and 80% drop-out of the nominal voltage. If different settings are required, please contact

Lake Shore Electric for assistance in changing these settings. In the event of a drop in any phase

of the preferred voltage below the dropout set point, the LSE8600 Controller will follow these

steps:

1.

The S1 light on the LSE8600 controller will turn off and the display will indicate a warning

under the "Alarm" screen menu.

2.

The "S2 Start Delay" will time for the Factory Default setting of 3 seconds. This would be

the standard "Engine Generator Start Delay" time to avoid nuisance transfers.

3.

Then the "S1 Return Delay" will time for the Factory Default setting of 3 seconds. This

would be the standard "Time Delay to Emergency" to avoid premature loading of the

generator.

4.

The "NS" molded case unit will then be opened to remove the load from S1 source power.

5.

The "Non-Sync Transfer Timer" will time for the Factory Default setting of 0 seconds.

However, there is a prebuilt in timer of 3 seconds that cannot be changed below that setting

for this controller. However, the delay may be increased by changing the Factory Default

from 0 seconds to the desired time delay.

6.

The "ES" molded case unit will then be closed to connect the load to S2 source power.

NOTE: If overvoltage sensing is used, factory default settings would be 120% drop-out and 115%

pick-up of nominal voltage.

The Dual Motor ATS is used EXCLUSIVELY FOR SERVICE ENTRANCE (SE) RATED

TRANSFER SWITCHES because the dual motor design allows for the necessary condition of

having both switches in the "OFF" position so that the load is isolated and disconnected from both

sources.

The Dual Motor ATS is also used EXCLUSIVELY FOR CLOSED TRANSITION TRANSFER (CTT)

SWITCHES because the dual motor design allows for the necessary condition of having both

switches in the "ON" position so that the load is momentarily connected to both sources when

they are synchronized providing a "make before break" transfer.

(Refer to Individual Unit Wiring Diagrams Included with the Transfer Switch.)