O & M Manual – Insulated Case ATS Rev: October 2020

Publication Number:

MN0100700E

Version: V10.01.20

Page 8

1.

Construction

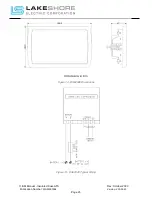

The Transfer Switches covered in this manual use molded case switches and/or circuit breakers

to accomplish the transfer of two separate power sources to a single load.

These molded case circuit breaker(s) and/or switch/switches, (molded case units), are interlocked

via electrical and mechanical control systems.

The LSE8600 Controller combined with the auxiliary contact switch located in the molded case

unit encompasses the electrical interlock system.

The physical "Plunger Style" interlock installed between the two molded case units

encompasses the mechanical interlock system. The interlock is located on the rear of the

base plate and is a fulcrum and lever device, which positively prevents both molded case

switches or circuit breakers from being in the ON position simultaneously.

The two control systems provide a redundant interlocking scheme which provides a "Fail-Safe"

design. Note: This mechanical interlock is not provided on units equipped with the Closed

Transition Option.

The gear motors are operated at 120Vac, supplied by the unit. The gear reduction unit is

permanently lubricated so that it requires no maintenance.

All styles of transfer switches are provided with an insulated operating handle to enable personnel

to manually operate the transfer switch in the event of an emergency. The handle is permanently

mounted and readily accessible and allows the operator to manually operate the transfer switch

under load.

All interface relays are of the enclosed industrial type to ensure long life and minimum

maintenance. They are rated for continuous duty to eliminate overheating of coils.

The LSE8600 controller will provide adequate control of the Automatic Transfer Switch (ATS).

These controllers offer programmable timers. Including the plant exerciser, and these values are

stored in non-volatile memory.