Lake Shore Model 642 Electromagnet Power Supply User’s Manual

3-8

Installation

3.6

POWER SUPPLY CONNECTOR

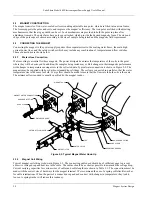

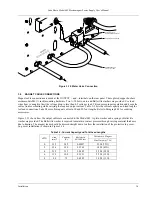

The Power Supply connector provides terminals for an optional water flow switch and an optional cooling water control

solenoid valve. The flow switch must have a normally closed contact rated at 5 V at 10 mA contact closure is required to

enable the Model 642 output. If a switch is not used, a jumper is required. 24 VAC at 1 A is provided to operate a water

control solenoid valve for the power supply cooling water. This output is controlled by the power supply, either

automatically via software, or manually through the Internal Water menu.

Water control is desirable to reduce water consumption when the water comes from a municipal facility. Turning the

water off when it is not required also reduces the probability of condensation within the power supply and connecting

tubing. If the cooling water comes from a facility chiller system, condensation is not usually a problem and a control

valve is not required. Figure 3-10 shows some typical Power Supply Connector wiring.

NO VALVE OR SWITCH

VALVE ONLY

SWITCH ONLY

VALVE AND SWITCH

Figure 3-10. Typical Power Supply Connector Wiring

3.7 COOLING

WATER

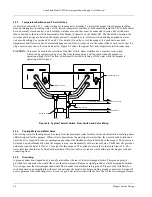

Two 10 mm (0.38 in) hose barbs are provided to connect to cooling water. The connection to the cooling water source

should be made with two 10mm (3/8 in) I.D. fiberglass reinforced hoses and two 20mm (25/32 in) adjustable hose

clamps. In addition, we recommend the installation of a sediment filter in the input line. A typical water hose connection

is shown in Figure 3-11.

The cooling water must be clean and free from sediment, salt and other contaminants, which might clog or erode the

water fittings. A minimum flow rate of 5.7 L (1.5 gal) per minute is required with a minimum pressure of 34 kPa (5 psi)

and a maximum pressure of 552kPa (80 psi). The temperature must be kept above 15

˚

C to avoid condensation and below

30

˚

C to ensure adequate system cooling. If water is drawn from a local municipal water source, the optional water valve

should be installed for economy and to prevent condensation (See 3.6 Power Supply Connector). If water is supplied by

a facility chiller, a valve can still be used but is not required.

CAUTION:

Dot use de-ionized water because it is corrosive to the water fittings inside the Model 642.

HOSE BARB FITTING

ON BACK PANEL OF 642

ADJUSTABLE HOSE CLAMP

REINFORCED HOSE

Figure 3-11. Typical Water Hose Connection

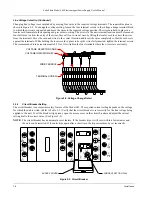

Figure 3-12 shows the connections required when a water valve is used. The optional solenoid water valve is supplied

mounted to a bracket which mounts to the rear of the Model 642 as shown in Figure 3-12. Hose connections are made as

shown in Figure 3-11.