LAKOS Waterworks PWC Series Separators

4

Separator Operation

continued…

Separator Model and Flow Chart

Model

*

Flow Range

Inlet/Outlet

ANSI Flange

Size

Collection

Chamber

Capacity

Weight Empty

Weight with

Water

US gpm

m³/hr

gal

liters

lbs

kg

lbs

kg

PWC-1040-L 225-525

51-119

4 inch

0.8

3.1

547

248

889

403

PWC-1040-V 225-525

51-119

4 inch

1.6

5.9

495

224

815

370

PWC-1050-L 305-800

69-181

6 inch

0.7

2.5

775

351 1394

632

PWC-1050-V 305-800

69-181

6 inch

3.0

11.2

752

341 1370

621

PWC-1060-L 480-1275 109-289

6 inch

1.3

4.8 1108

502 2304

1045

PWC-1060-V 480-1275 109-289

6 inch

6.2

24.3 1103

500 2297

1042

PWC-1080-L 820-2050 186-465

8 inch

2.1

8.1 1694

768 3858

1750

PWC-1080-V 820-2050 186-465

8 inch

7.8

29.4 1689

766 3757

1704

Separator Model and Flow Chart

* Suffix “L” refers to low profile; suffix “V” refers to vertical profile. IMPORTANT: Separator must operate within flow range

for optimum performance

4 inch

6 inch

6 inch

8 inch

PWC-1040-L

PWC-1040-V

PWC-1050-L

PWC-1050-V

PWC-1060-L

PWC-1060-V

PWC-1080-L

PWC-1080-V

0.8

1.6

0.7

3.0

1.3

6.4

2.1

7.8

3.1

5.9

2.5

11.2

4.8

24.3

8.1

29.4

547

495

775

752

1108

1103

1694

1689

889

815

1394

1370

2304

2297

3858

3757

248

224

351

341

502

500

768

766

403

370

632

621

1045

1042

1750

1704

240-540

370-820

550-1200

940-2060

55-123

84-186

125-273

213-468

Models ending with "L" are low profile; "V" are vertical profile

Flow range is critical to separator performance. Do not oversize separator or use pipe size for model selection

See page 6 for higher flow rates and variable flow systems

1-1/2"

1-1/2"

1-1/2"

1-1/2"

Flow Range**

U.S. gpm

m

3

/hr

gal

liters

lbs.

kg

kg

lbs

Model*

Weight

Empty

Weight

with Water

Collection

Chamber Capacity

Inlet/Outlet

ANSI

Flange

Purge

Size

Male N.P.T.

*

**

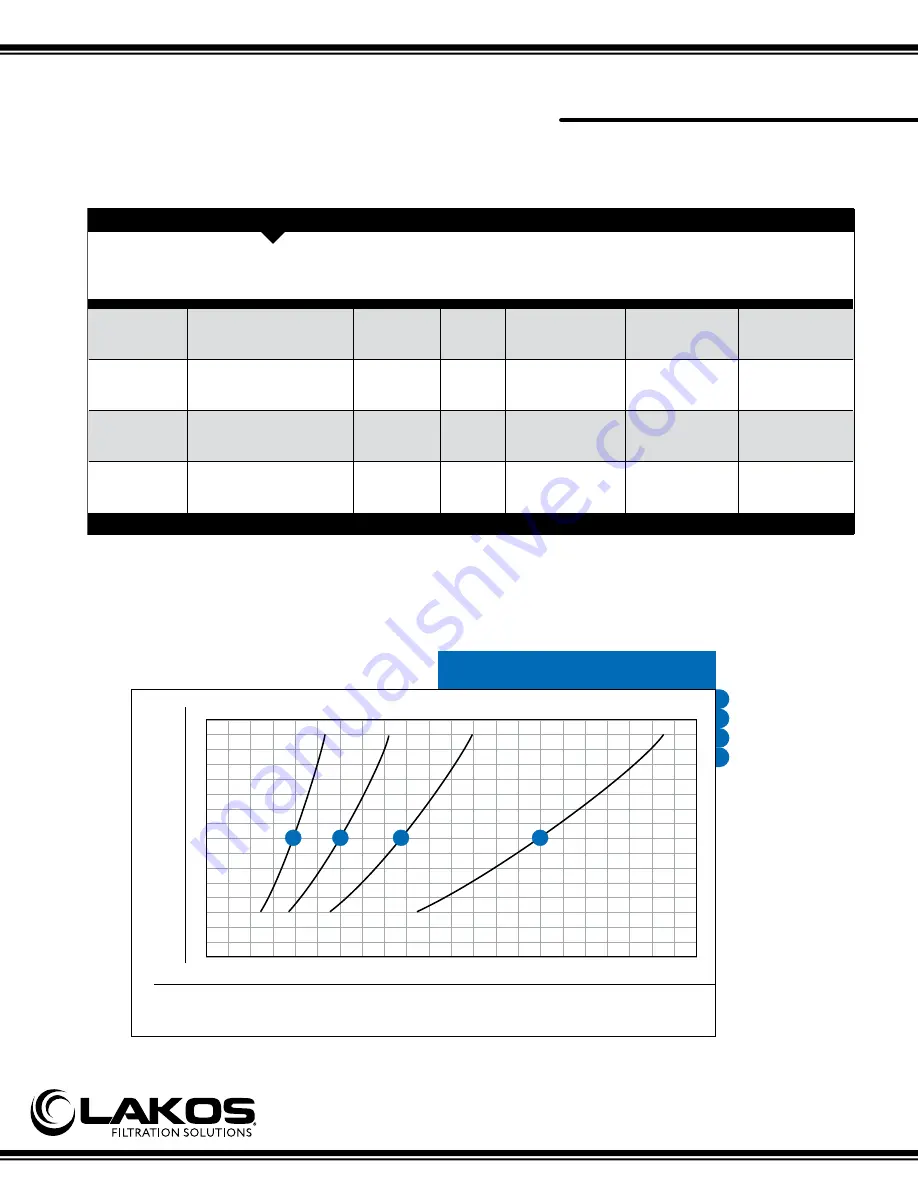

Flow vs. Pressure Loss

PWC-1040

PWC-1050

PWC-1060

PWC-1080

A

B

C

D

Pressure Loss

Flow Rate

Flow range is critical for model selection. Do not use flange size.

psi

bar

(gpm)

(m

3

/hr)

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1.10

1.03

0.97

0.90

0.83

0.76

0.69

0.62

0.55

0.48

0.41

0.34

0.28

0.21

0.14

0.07

0

0

100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200

0 23 45 68 91 114 136 159 182 204 227 250 273 295 318 341 363 386 409 432 454 477 500

A

B

C

D

4 inch

6 inch

6 inch

8 inch

PWC-1040-L

PWC-1040-V

PWC-1050-L

PWC-1050-V

PWC-1060-L

PWC-1060-V

PWC-1080-L

PWC-1080-V

0.8

1.6

0.7

3.0

1.3

6.4

2.1

7.8

3.1

5.9

2.5

11.2

4.8

24.3

8.1

29.4

547

495

775

752

1108

1103

1694

1689

889

815

1394

1370

2304

2297

3858

3757

248

224

351

341

502

500

768

766

403

370

632

621

1045

1042

1750

1704

240-540

370-820

550-1200

940-2060

55-123

84-186

125-273

213-468

Models ending with "L" are low profile; "V" are vertical profile

Flow range is critical to separator performance. Do not oversize separator or use pipe size for model selection

See page 6 for higher flow rates and variable flow systems

1-1/2"

1-1/2"

1-1/2"

1-1/2"

Flow Range**

U.S. gpm

m

3

/hr

gal

liters

lbs.

kg

kg

lbs

Model*

Weight

Empty

Weight

with Water

Collection

Chamber Capacity

Inlet/Outlet

ANSI

Flange

Purge

Size

Male N.P.T.

*

**

Flow vs. Pressure Loss

PWC-1040

PWC-1050

PWC-1060

PWC-1080

A

B

C

D

Pressure Loss

Flow Rate

Flow range is critical for model selection. Do not use flange size.

psi

bar

(gpm)

(m

3

/hr)

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1.10

1.03

0.97

0.90

0.83

0.76

0.69

0.62

0.55

0.48

0.41

0.34

0.28

0.21

0.14

0.07

0

0

100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200

0 23 45 68 91 114 136 159 182 204 227 250 273 295 318 341 363 386 409 432 454 477 500

A

B

C

D

LAKOS Waterworks PWC Series Separators

4

Separator Operation

continued…

Separator Model and Flow Chart

Model

*

Flow Range

Inlet/Outlet

ANSI Flange

Size

Collection

Chamber

Capacity

Weight Empty

Weight with

Water

US gpm

m³/hr

gal

liters

lbs

kg

lbs

kg

PWC-1040-L 225-525

51-119

4 inch

0.8

3.1

547

248

889

403

PWC-1040-V 225-525

51-119

4 inch

1.6

5.9

495

224

815

370

PWC-1050-L 305-800

69-181

6 inch

0.7

2.5

775

351 1394

632

PWC-1050-V 305-800

69-181

6 inch

3.0

11.2

752

341 1370

621

PWC-1060-L 480-1275 109-289

6 inch

1.3

4.8 1108

502 2304

1045

PWC-1060-V 480-1275 109-289

6 inch

6.2

24.3 1103

500 2297

1042

PWC-1080-L 820-2050 186-465

8 inch

2.1

8.1 1694

768 3858

1750

PWC-1080-V 820-2050 186-465

8 inch

7.8

29.4 1689

766 3757

1704

Separator Model and Flow Chart

* Suffix “L” refers to low profile; suffix “V” refers to vertical profile. IMPORTANT: Separator must operate within flow range

for optimum performance