VI.

MAINTENANCE

1.

A STS System START-UP FORM is included in this manual Record all

readings (inlet and outlet pressures, motor amperage draw and

liquid flow rate) during start-up as reference point (see note 3). Please

complete the required information and return this form to your local

representative as soon as possible. You may want to keep a copy for your

records.

2.

Record and compare these readings whenever periodic check-up and

maintenance is required. These records would be helpful in troubleshooting

the system when a problem occurs during the operational life of the system.

A.

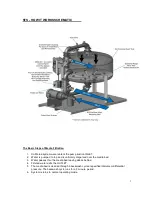

SUCTION STRAINER BASKET:

The suction strainer basket is sized to allow a maximum pressure

drop of 2 psi at the specified flow rate. It will protect the pump,

separator, flow control valves and other equipment from becoming

plugged by dirt and debris 1/4” in size and greater. The strainer

basket is easy to clean. Isolate the strainer by closing the isolation

valves installed before the pump and after the separator outlet. These

are not provided as a standard option by Lakos, but are available if a

valve kit is ordered. Loosen the nuts or threaded stud and remove the

lid. Remove the basket and clean. Inspect the ‘O’ ring or gasket and,

if damaged, replace. Replace the lid and tighten the nuts.

B.

PUMP AND MOTOR

Make sure that there are no leaks in the pump housing. If leaks occur

at the back of the volute casing, you may have a damaged the seal

(pump seals are not covered under warranty) and/or loose bolts.

Replace and/or tighten as necessary.

Whenever maintenance or repair is needed for the pump, SHUT-OFF

and LOCK-OUT power into the panel feeding the pump; close the

suction and discharge valves, open drain plug/valve, making sure no

air or hydraulic pressure is in the system before unhooking the pump.

Refer to Pump Manual.

Outside air is very important to cool the motor. The TEFC motor has a

fan in the back. Ensure that the fan is rotating when motor is

energized. Zerk fittings were installed in the front and back of the

pump shaft/bearing housing. A small amount of grease might be

needed periodically to replenish the old grease in the housing.

Whenever new grease is injected, the old grease will ooze out on the

11