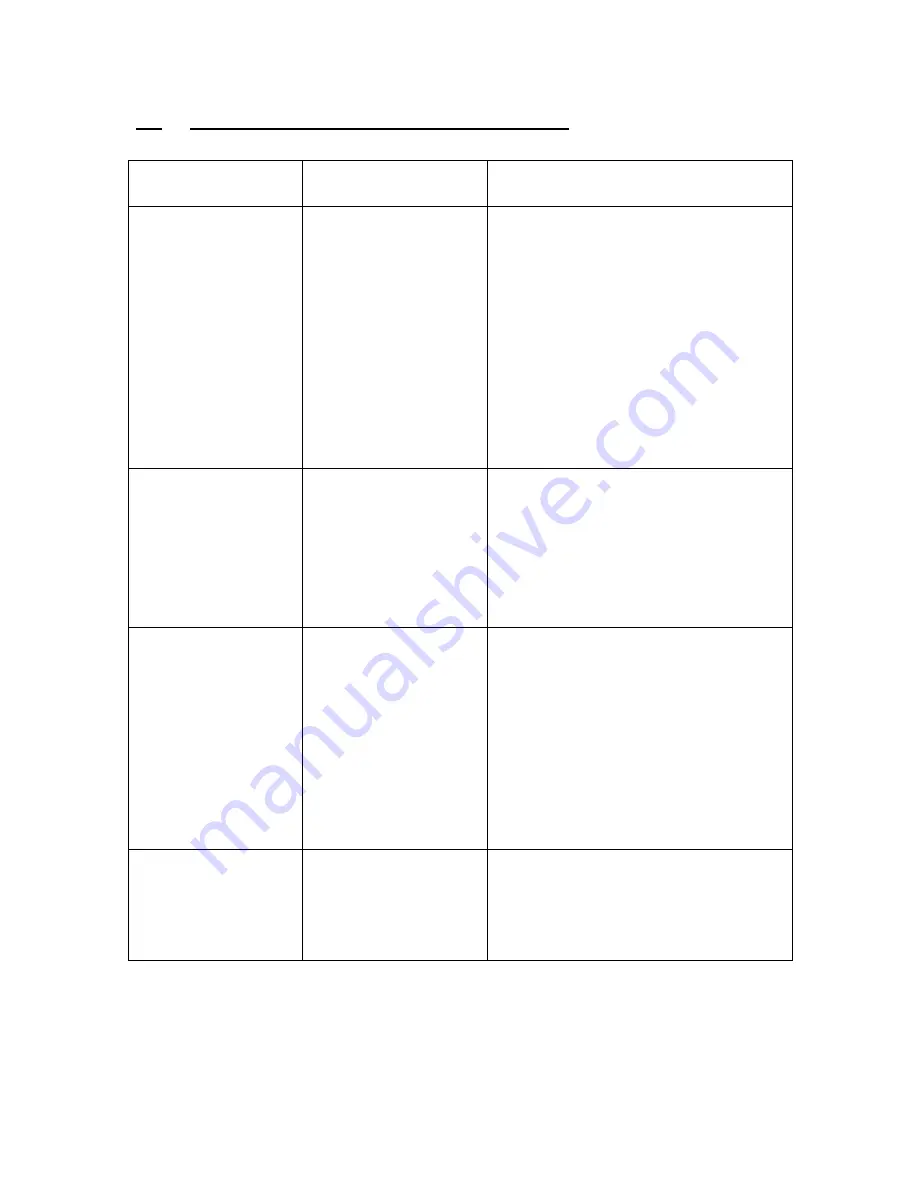

VII. TROUBLE SHOOTING PROCEDURES (con’t)

PROBLEM

POSSIBLE

CAUSES

SOLUTIONS

Pump will not prime

(standard, not self-

priming)

Suction line is not

flooded with water.

Debris in basket

strainer.

Air leaks.

Pump rotating wrong

direction.

1. Check and clean out pump suction pre-

strainer as required.

2. Check and clean pump pre-strainer as

required.

3. Check and tighten all connections as

required.

4. Check pump rotation against motor

rotation arrow and rewire if necessary

for proper rotation.

Pump motor runs hot

Motor located in

direct sunlight.

Poor ventilation.

Low voltage

1. Cover motor with some type of sun

shade if possible.

2. All motors require air movement for

cooling. Make sure that motor has a

fresh source of air for cooling.

3. Check voltage with meter.

System “Trips” out when

running and shuts down

Overload setting is

too low.

Supply voltage is

incorrect.

System flow is too

high.

Loose Wire.

1. Check overload setting in control panel.

Overload setting should be just above

full load amp value on motor nameplate.

2. Check incoming supply voltage with

STS system power requirements

located on control panel door (outside

and inside).

3. Install valve on system discharge

to control flow.

4. Check all wires for loose connections.

Unit stays in backwash

or valves do not operate

correctly

Incorrect timer

settings.

Wire may be loose or

wired incorrectly.

1. Refer to Section IV Paragraph 12 for

factory settings.

2. Contact factory while onsite if possible

for further troubleshooting review.

16