83-507-013 Rev. A

39

+S

+

-

-S

-LS

+LS

POWER

SUPPLY

+S

+

+

-

-

-S

-LS

+LS

POWER

SUPPLY

LOAD

+S

+

-

-S

-LS

+LS

POWER

SUPPLY

+S

+

+

-

-

-S

-LS

+LS

POWER

SUPPLY

LOAD

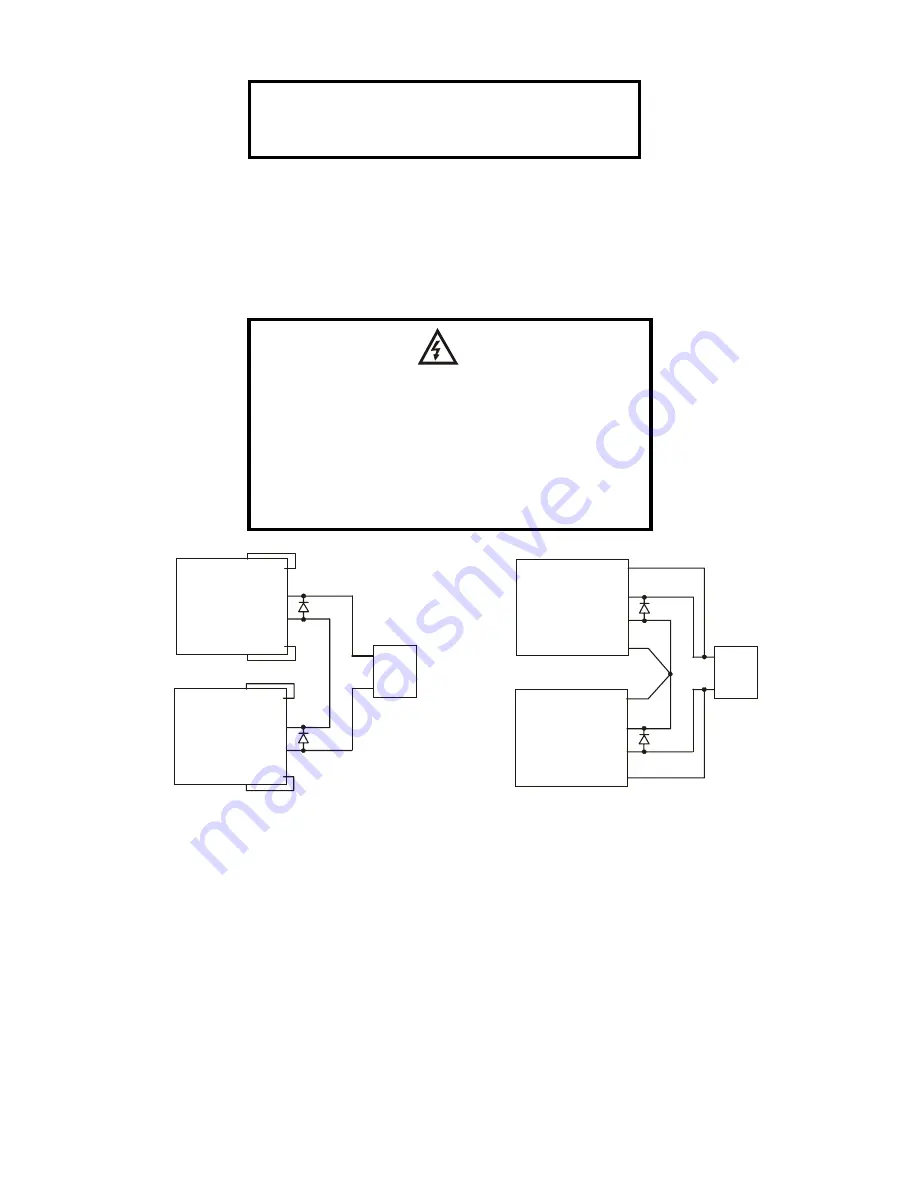

Fig.5-1: Series connection, local sensing

Fig.5-2: Series connection, remote sensing

(*)

(*)

(*)

(*)

(*) Diodes are

user supplied.

5.14.1 Series connection for increased output voltage

In this mode, two units are connected so that their outputs are summed. Set the Current of each power

supply to the maximum that the load can handle without damage. It is recommended that diodes be con-

nected in parallel with each unit output to prevent reverse voltage during start up sequence or in case

one unit shuts down. Each diode should be rated to at least the power supply rated Output Voltage and

Output Current. Refer to Fig.5-1 and 5-2 for series operation with local and remote sensing.

Remote

programming in series operation for increased output voltage:

1. Programming by external voltage:

The analog programming circuits of this power supply are

referenced to the negative output potential. Therefore, the

circuits used to control each series connected unit must be

separated and floated from each other.

2.Using the SO function and PS_OK signal: The Shut-Off and PS_OK circuits are referenced to the iso-

lated interface common, IF_COM (J1-2,3). The IF_COM

terminals of different units can be connected to obtain a

single control circuit for the power supplies connected in

series.

CAUTION

Do not connected power supplies from different

manufacturers in series or in parallel.

WARNING

When power supplies are connected in series, and

the load or one of the output terminals is grounded,

no point may be at a greater potential of +/-60VDC

from ground for models up to 60VDC Rated Output

and +/-600VDC from ground for models >60VDC

Rated Output. When using RS232/RS485 or IEEE,

refer to the OUTPUT TERMINALS GROUNDING

warning in Section 3.9.11.