11

DAY MAINTENANCE

- Disconnect the machine with

pushbutton "A";

-

Lift the overflow pipe and let

the water

drain out of the

tank;

-

Wash thoroughly the tank and

the filters

housing to remove

all impurities;

-

Take the filters and clean it under

running

water;

-

Re-assemble the overflow pipe

and the

filters in their

housings;

-

Check and clean the washing and

the rinsing jets;

-

Clean the outer surface of the

machine by using a wet sponge;

don't use water jets because,

beside being dangerous they

could damage the electrical parts;

don't use abrasive detergents;

-

When the machine is to remain

idle for a

long time, drain all

the water from the

boiler

(the drain plug is located on

the

lower side of the boiler)

and from the

electropump.

Also leave the wash tank

open.

NEVER WASH THE EXTERNAL PART OF

THE MACHINE WITH A WATER JET

POSSIBLE TROUBLES - CAUSES - SOLUTIONS

PROBLEMS

CAUSES

SOLUTIONS

The machine doesn't catch

Main switch is switched off;

Turn ON the main switch;

The water doesn't go in

Water cock closed;

Open water cock;

The Overflow is not in its place;

Reassemble the Overflow in its

place;

Insufficient Washing

Wrong detergent or dosage

Use anti-foam detergent in the

insufficient;

right dosage and never with

cold water;

Low temperature in the tank;

Wait untill the water gets hot;

Dirt wash filter;

Clean filter;

Insufficient Rinsing

Rinsing nozzles blocked;

Unscrew and clean nozzles

under running water;

Hydraulic pressure lower than

Wait till the pressure is on or buy

1 bar - 100 kPa;

a booster pump;

CAUTION! FOR ANY OTHER TROUBLE, CALL SERVICE

Summary of Contents for PT1500M-ek

Page 1: ...POT WASHING MACHINES INSTRUCTIONS MANUAL PT850M ek PT1500M ek...

Page 6: ...INSTRUCTIONS FOR THE USER...

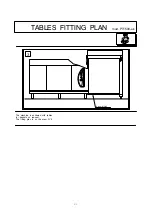

Page 14: ......

Page 15: ......

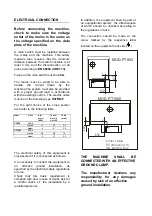

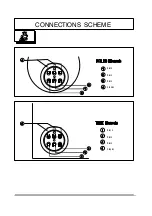

Page 22: ...CONNECTIONS SCHEME Black Black Black Black Staples Black Black Staples...

Page 27: ......