26

DRAWBACK

POSSIBLE CAUSES AND REMEDIES

If the drawback is not due to any of the

causes listed here above, proceed as follows:

In the case of electrical heating machines

1) check that the coil of remote switch MT3

is not broken.

2) check that the safety thermostat MT4 did

not trigger.

3) check all elements of boiler heater R1.

In the case of steam heating machines

1) check that the steam inlet gate is open

and is present at a pressure not less than

0,5 bar (50 kPa).

2) check that the condensed steam

drainage filter is not clogged.

3) check that the steam solenoid valve EV7

operates correctly.

4) check that the inlet steam filter is not

clogged to such an extent as to prevent the

normal flow rate.

5) check that the condensed steam outlet

pipe can freely drain by drop.

6) check that the pipe coil is not scaled to

such an extent as to limit heat exchange

thereof.

The manufacturer declines any responsibility for any printing errors contained in this booklet.

The manufacturer also reserves the right to make any modifications to its products that don't

affect the basic characteristics thereof.

Summary of Contents for PT1500M-ek

Page 1: ...POT WASHING MACHINES INSTRUCTIONS MANUAL PT850M ek PT1500M ek...

Page 6: ...INSTRUCTIONS FOR THE USER...

Page 14: ......

Page 15: ......

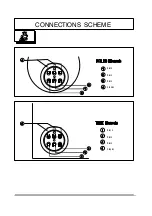

Page 22: ...CONNECTIONS SCHEME Black Black Black Black Staples Black Black Staples...

Page 27: ......