Printed 07-2001

-5-

Form No. M1-0002

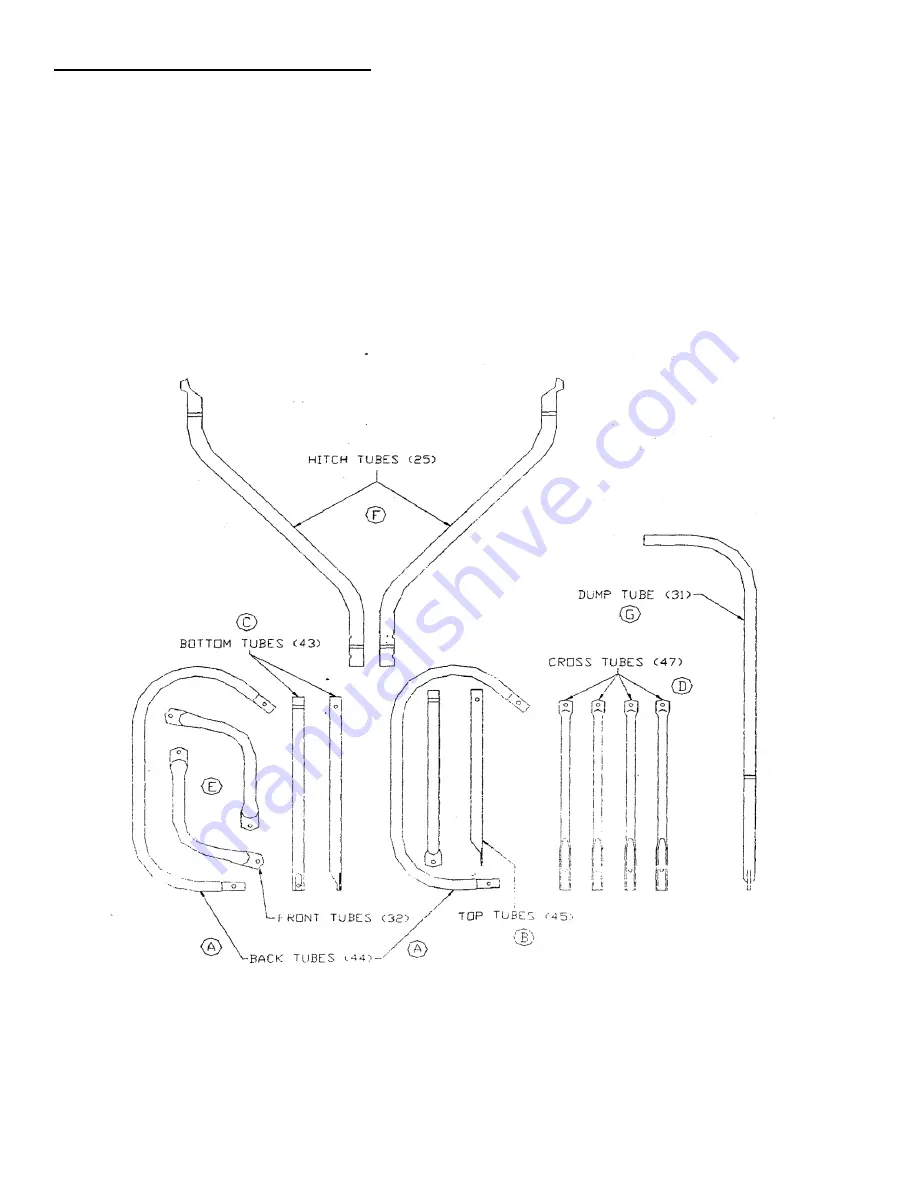

TUBING IDENTIFICATION: (NOT TO SCALE)

A. Hamper Back Tubes (44): Curved on both ends with the greater curve being the top.

B. Hamper Top Tubes (45): Shorter than Bottom Tube (43), flattened and rounded on one end.

C. Hamper Bottom Tube (43): Longer than Top Tube (45), channeled on one end.

D. Hamper Cross Tube (47): Smaller diameter than all other tubing, flattened and rounded on one end and concave on

the other end.

E. Hamper Front Tube (32): Shortest tube, flattened and rounded on each end.

F. HITCH TUBES (25).

G. DUMP HANDLE (31).