37

●

After removing the packaging materials, check the content integrity and make sure that no damages have

occured during transportation. In case of doubt, do not use the burner and contact the supplier.

The packaging material (wooden cages, cartons, plastic bags, foam, clips, etc...) are

potential sources of pollution and danger, if left lying around; they should be collected up and disposed of

in the correct way (in a suitable place).

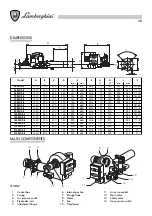

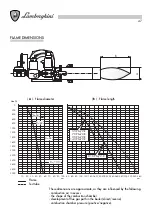

These are natural gas burners with a mix of gas/air to the combustion head and reduced capacity start-up.

The structure of the combustion head enables the use of all natural gases, mixes and liquids (consult technical

assistance for specific information). The gas/air mix makes it possible to obtain combustion with a low excess

of air, leading to a high combustion efficiency and low CO and NOx emissions, and consequently a low

environmental impact. They are suitable for pressurised and negative pressure furnaces, according to the

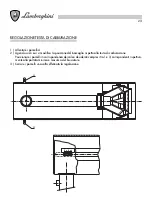

relative operating curves. With a long draught tube sliding on a flange, the burners make it possible to adapt

the length of the insertion to the requirements of the boiler. The gas train can be installed on the right or left (on

request). Complete access is easily achieved by means of the hinged opening between the casing and the

burner head, without removing the gas line connection. The burners operate automatically and have ionisation-

probe flame control.

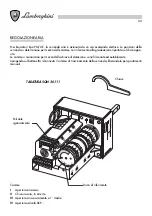

The

PM/2-E

series burners have a two-stage operation with start-up in two-interval , and closing of air on

stopping. The burners are available with different valve sizes according to the gas flow rate required and the

gas pressure (and boiler) available.

DESCRIPTION