319

EN

cod. 3541V620 - Rev. 00 - 05/2021

ALHENA TECH H

3. Service and maintenance

B

All adjustments described in this chapter can only be

carried out by qualified personnel.

3.1 Adjustments

Gas conversion

The unit can work with

2

nd

or

3

rd

family gases, which is clearly indicated on the packaging and on

the data plate of the unit. If the unit has to be used with a gas other than the factory-set one, pro-

ceed as follows:

1. Disconnect the power supply and turn off the gas.

2. Remove the front panel (

see *** 'Opening the front panel' on page 326 ***

).

3. Apply the plate for LPG (contained in the document bag) near the technical data plate.

4. Refit the front panel and turn on the power to the boiler.

5.

Modify the parameter for the type of gas

:

• Access the

Main menu [MENU]

using the button

.

• Follow the path

installer menu [Service]

>enter the

Password 1234

(see fig. 17) >

param-

eters menu [TSP]

.

• Using the buttons

and

Heating,

select parameter

b03

and set the corresponding val-

ue with the buttons

and

DHW

:

0 =G20

1 =G30/G31

2 =G230

• To confirm, press the button

.

• Turn the power off for 10 seconds and then back on.

• Wait until the

Fh

mode has finished.

• Put the boiler in standby mode and activate the

calibration mode[AUTO SETUP]

(see ***

'IMPORTANT' on page 319 ***).

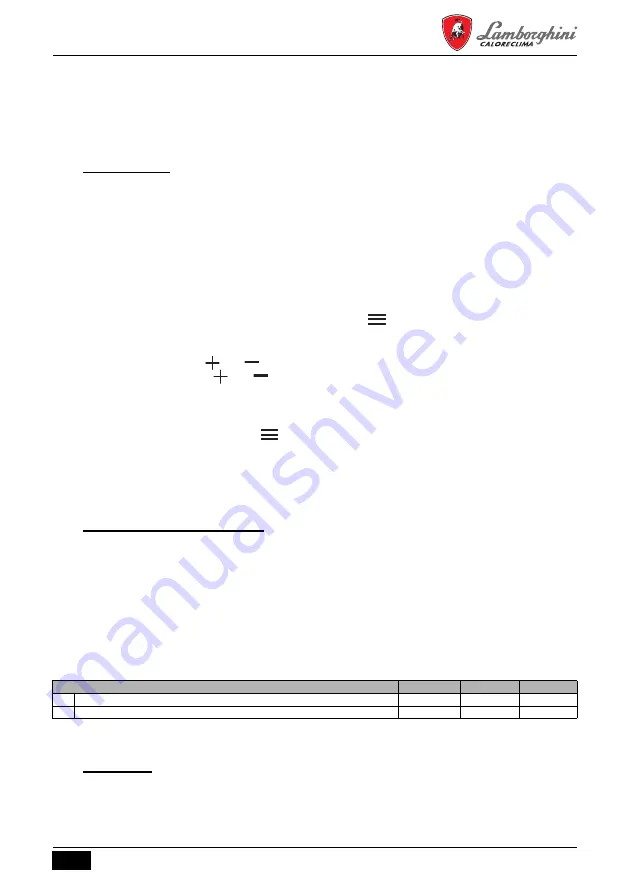

Checking the combustion values

MAKE SURE THE FRONT PANEL IS CLOSED AND THE INTAKE/FUME EXHAUST DUCTS

ARE COMPLETELY ASSEMBLED.

1. Put the boiler in heating mode for at least 2 minutes.

2. Activate the

Test [TEST]

mode (see *** 'Test mode [Test]' on page 321 ***).

3. Using a combustion analyzer connected to the arrangements located on the starting accesso-

ries above the boiler, with boiler operating at maximum and minimum power check that the CO

2

content in the fumes matches that indicated in the following table.

4. If the combustion values do not match, adjust the Offset values in the

Test mode

as described

in the following paragraph.

IMPORTANT

B

During the CALIBRATION PROCEDURE [AUTO SET-

UP], the TEST PROCEDURE [TEST] or during the CO

2

Case studies

G20

G30/G31

G230

A

New boiler (first ignition/conversion or electrode replacement)

7.5%-9.9%

9%-11.5%

9%-11.5%

B

Boiler with at least 500 hours of operation

9%+/-0.8

10%+/-0.8

10%+/-0.8

Summary of Contents for ALHENA TECH H

Page 45: ...45 IT cod 3541V620 Rev 00 05 2021 ALHENA TECH H fig 48 fig 49 fig 50 5 6 6...

Page 103: ...103 ES cod 3541V620 Rev 00 05 2021 ALHENA TECH H fig 48 fig 49 fig 50 5 6 6...

Page 160: ...160 RO cod 3541V620 Rev 00 05 2021 ALHENA TECH H fig 48 fig 49 fig 50 5 6 6...

Page 217: ...217 PL cod 3541V620 Rev 00 05 2021 ALHENA TECH H wygl d 48 wygl d 49 wygl d 50 5 6 6...

Page 231: ...B 231 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H...

Page 232: ...232 EL B CE IT ES RO PL GR cod 3541V620 Rev 00 05 2021 A ALHENA TECH H 8 8...

Page 238: ...238 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H FH Fh 2 10 0 FH 2 Stop...

Page 249: ...249 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H 3 27 27 b09 1 1 2bar 0 7bar F37 3...

Page 250: ...250 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H 2 2 1 2 2 B 2009 142 5 C 15 C A 2 3 B...

Page 253: ...253 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H 2 5 B B 3 mm 3A...

Page 254: ...254 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H B HAR H05 VV F 3x0 75 mm2 8 mm B 230 V...

Page 262: ...262 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H B 2 7 B 0 5 lt B 37...

Page 271: ...271 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H 1 1 41 2 41 B 1 42 42 OK NO 1 1...

Page 273: ...273 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H 1 43 2 43 3 44 4 5 45 43 44 45 1 2 3 4 5...

Page 274: ...274 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H A B 1 2 5 49 2 6 50 5 46 47 1...

Page 275: ...275 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H 48 49 50 5 6 6...

Page 276: ...276 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H 1 2 3 4 51 52 1 1 2 2 3 3 4...

Page 277: ...277 EL cod 3541V620 Rev 00 05 2021 ALHENA TECH H 1 2 venturi 3 53 54 A 1 2 55 2 1 1 1 2...

Page 330: ...330 EN cod 3541V620 Rev 00 05 2021 ALHENA TECH H fig 48 fig 49 fig 50 5 6 6...

Page 343: ......