AXE 3 D

15

EN

cod. 3540Z230 - 01/2011 (Rev. 00)

4.3 Maintenance

Periodical check

To ensure correct operation of the unit over time, have qualified personnel carry out a

yearly check, providing for the following:

•

The control and safety devices must function correctly.

•

The fume exhaust circuit must be perfectly efficient.

•

Check there are no obstructions or dents in the fuel supply and return pipes.

•

Clean the filter of the fuel suction line.

•

Measure the correct fuel consumption

•

Clean the combustion head in the fuel outlet zone, on the swirl disc.

•

Leave the burner running at full rate for approximately ten minutes, then analyse

the combustion, checking:

-

All the elements specified in this manual are set correctly

-

Temperatures of the fumes at the flue

-

CO2 percentage content

•

The air-fume end piece and ducts must be free of obstructions and leaks

•

The burner and exchanger must be clean and free of deposits. For possible clean-

ing do not use chemical products or wire brushes.

•

The gas and water systems must be airtight.

•

The water pressure in the cold water system must be approx. 1 bar; otherwise, bring

it to that value.

•

The circulating pump must not be blocked.

•

The expansion tank must be filled.

•

Check the magnesium anode and replace it if necessary.

A

The boiler casing, control panel and aesthetic parts can be cleaned with a soft

and damp cloth, if necessary soaked in soapy water. Do not use any abrasive

detergents and solvents.

Boiler cleaning

1.

Disconnect the power supply to the boiler.

2.

Remove the front top and bottom panel.

3.

Open the door by undoing the knobs.

4.

Clean the inside of the boiler and the entire path of exhaust fumes, using a tube

brush or compressed air.

5.

Then close the door, securing it with the knob.

To clean the burner, refer to the Manufacturer's instructions.

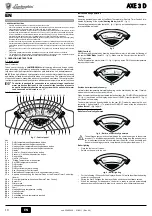

4.4 Troubleshooting

Diagnostics

The boiler is equipped with an advanced self-diagnosis system. In case of a boiler anom-

aly, the display will flash together with the fault symbol (detail 22 - fig. 1) indicating the

fault code.

There are faults that cause permanent shutdown (marked with the letter “

A

”): to restore

operation press the RESET button (detail 8 - fig. 1) for 1 second or RESET on the op-

tional remote timer control if installed; if the boiler fails to start, it is necessary to eliminate

the fault indicated by the operation LEDs.

Other faults (marked with the letter “

F

”) cause temporary shutdowns that are automati-

cally reset as soon as the value returns within the boiler's normal working range.

Table. 2 - Fault list

5. TECHNICAL DATA AND CHARACTERISTICS

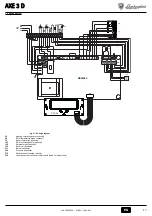

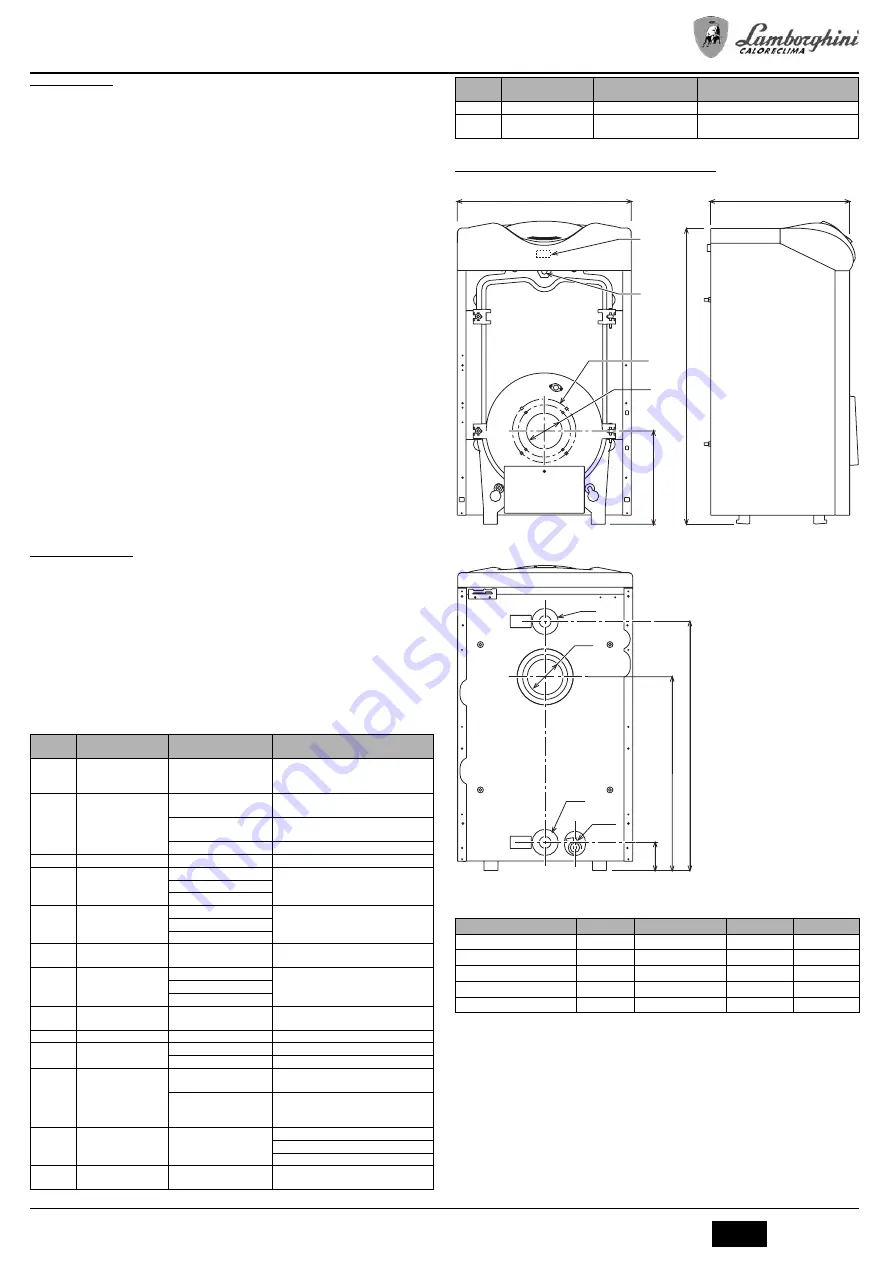

5.1 Dimensions, connections and main components

fig. 19 - Dimensions, connections and main components

10

System delivery 1" 1/2"

11

System return 1" 1/2"

246

Heating system pressure transducer

275

Heating system drain cock

278

Double sensor ( heating)

Fault

code

Fault

Possible cause

Cure

A01

Burner shutdown

(RESET ONLY OCCURS

ON THE BURNER)

Refer to the burner manual

A03

Overtemperature protec-

tion activation

Heating sensor damaged

Check the correct positioning and operation of

the heating sensor

No water circulation in the

system

Check the circulating pump

Air in the system

Vent the system

F07

Wiring fault

Connector X5 not connected Check the wiring

F10

Delivery sensor 1 fault

Sensor damaged

Check the wiring or replace the sensor

Wiring shorted

Wiring disconnected

F11

DHW sensor fault

Sensor damaged

Check the wiring or replace the sensor

Wiring shorted

Wiring disconnected

F13

Wiring fault

Connector X12 not con-

nected

Check the wiring

F14

Delivery sensor 2 fault

Sensor damaged

Check the wiring or replace the sensor

Wiring shorted

Wiring disconnected

F34

Supply voltage under

170V.

Electric mains trouble

Check the electrical system

F35

Mains frequency fault

Electric mains trouble

Check the electrical system

F37

Incorrect system water

pressure

Pressure too low

Fill the system

Sensor damaged

Check the sensor

F39

External probe fault

Probe damaged or wiring

shorted

Check the wiring or replace the sensor

Probe disconnected after

activating the sliding temper-

ature

Reconnect the external probe or disable the

sliding temperature

F40

Incorrect system water

pressure

Pressure too high

Check the system

Check the safety valve

Check the expansion tank

A41

Sensor positioning

Delivery sensor not inserted

in boiler shell

Check the correct positioning and operation of

the heating sensor

F42

Heating sensor fault

Sensor damaged

Replace the sensor

F47

System water pressure

sensor fault

Wiring disconnected

Check the wiring

A

Ø a4

Ø a5

Ø a6

AXE 3 D 32

400

120-130

105

150

AXE 3 D 45

500

120-130

105

150

AXE 3 D 59

600

120-130

105

150

AXE 3 D 74

700

120-130

105

150

AXE 3 D 90

830

120-130

125

170

Fault

code

Fault

Possible cause

Cure

268

500

850

A

553

65

71

1

a4

10

11

275

a5

a6

246

278