46

UK

OPERATION WITH DIFFERENT TYPES OF GAS

MAINTENANCE

M

Skilled staff has to perform yearly the following operations:

- Check the valve inside tightness.

- Filter cleaning.

- Fan and head cleaning.

- Check the position of the ignition electrode tips as well as the control electrode.

- Calibrate the air and gas pressure switches.

- Check the combustion by means of CO2-CO-FUMES TEMPERATURE bearings.

- Check all the gaskets and seal tightness.

Close the fuel aspiration gate and, depending on the type, proceed with thorough clea-

ning of the filtration component. To check whether the air gate fan is clean or to check

the combustion head proceed as follows:

- Remove the cover (1) by loosening the screw (2).

- Loosen the lower screws (3) completely.

- Parzially loosen the upper screws (4) too.

- Release by raising the component support plate (5) and hook it in its seat as illustrated

in figure

Doing the above provides the conditions needed to check whether the internal burner

parts are clean and, where necessary, to replace the motor-fan unit. When re-assembling

make sure that you observe the gap illustrated in figure.

WARNING: in the event of a dangerous situation cut power by turning the main switch

to OFF and stop fuel flow via the relative gate.

M

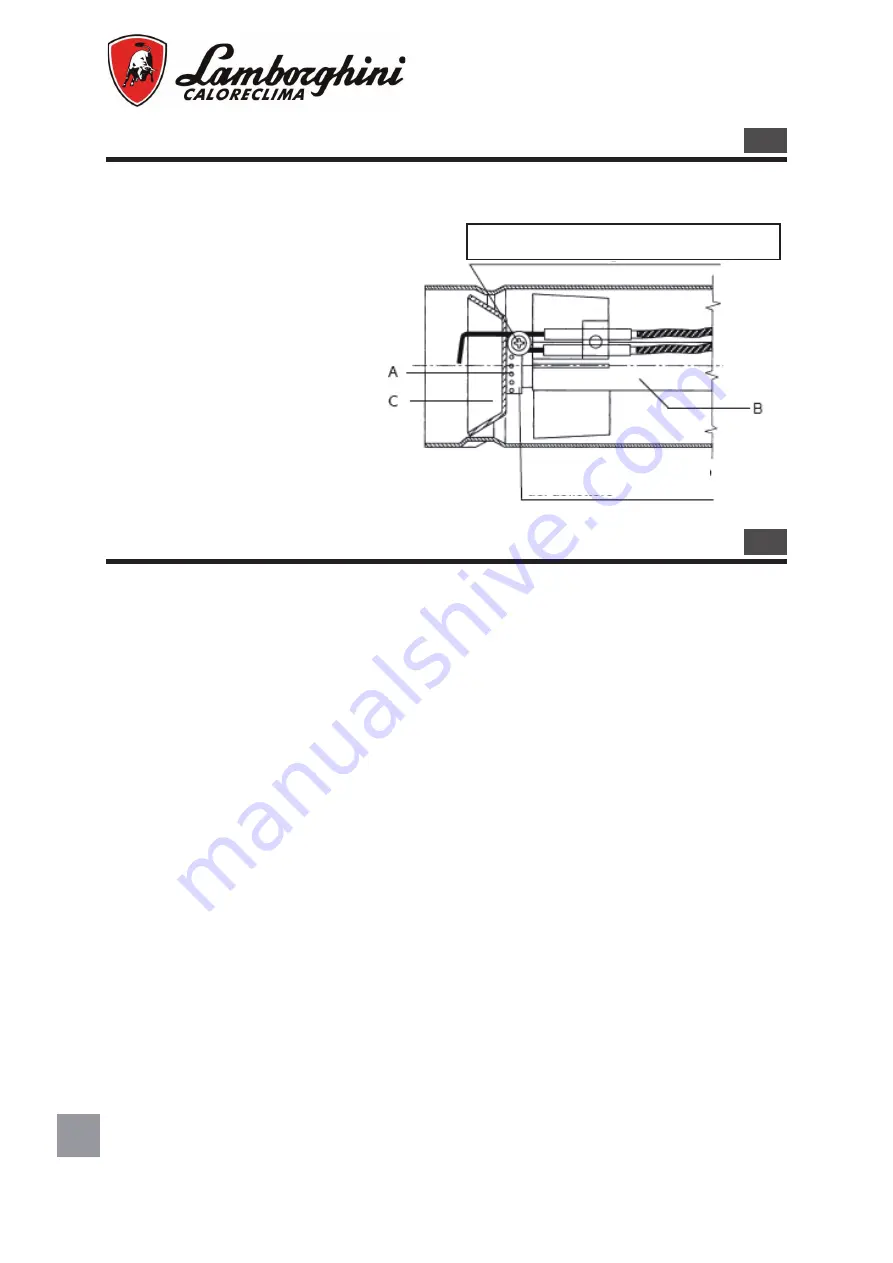

CONVERSION FROM NATURAL GAS TO B/P

A specific burner is not previewed.

Should you wish to convert the

burner from natural gas to other

types of gas, bear in mind that it

is necessary to move the ring nut

A situated on the supply pipe B to-

wards the diffuser C, so as to clo-

se the gas outlet holes in models

EM 3 ST/EM 6 N ST .

Bring the ring nut into contact

with the diffuser

The ring nut locking screw must be in the

electrodes area