iXinox 24 C

23

EN

cod. 3541N452EN - Rev. 03 - 03/2020

100% calibration

IMPORTANT: DURING THE AUTOMATIC CALIBRATION PROCEDURE AND CHECK OF THE CO

2

VALUE, THE

FRONT CASING OF THE BOILER MUST BE CLOSED AND THE INTAKE/FUME EXHAUST DUCTS COMPLETELY

ASSEMBLED.

100% calibration, manual

Calibration procedure

.

•Put the boiler (preferably) in heating mode or else in DHW mode. Press the

Reset

button (detail 6 - fig. 1) for 10 se-

conds.

•The display shows 100 and the text

”Co”

flashing; press the "H" button (ref. 4 fig. 1) to set and view 120.

•Then press the "DHW +" button (ref. 2 fig. 1) to set 123.

•Press the

Reset

button (ref. 6 fig. 1) once.

•The display shows

Ts

flashing; press the "h" button (ref. 4 fig. 1) once.

•The display shows

Sc

flashing; press the

reset

button once.

•The display shows

Sc

alternating with 01 flashing;

•Press the "h" button (ref. 4 fig. 1) until displaying

Sc

alternately with 15 flashing;

•Press the "DHW +" button and the display shows "00";

•Press the "DHW +" button and the display shows "01";

•Press the "h" button (ref. 4 fig. 1) and the 100% calibration mode will activate, displaying the message “CA ”

and “LI” alternating.

•After calibration, the display will show

Sc

alternating with 15 flashing.

•Press Reset (ref. 6 fig. 1) for 10 seconds to exit the

Sc

menu.

100% calibration, automatic

Automatic calibration can take place in some cases in the absence of a DHW or heating demand or after a reset due to

a fault and is indicated on the display by the flashing flame symbol.

Loading parameters with “BCC KEY”

The

“BCC KEY”

device allows the updating of combustion parameters for boiler type.

It is used in case of replacement of the PCB of some boiler models.

To use the

“BCC KEY”

, refer to the instructions contained in the

kit code 3980H730

.

TEST mode activation

Perform a heating or DHW demand.

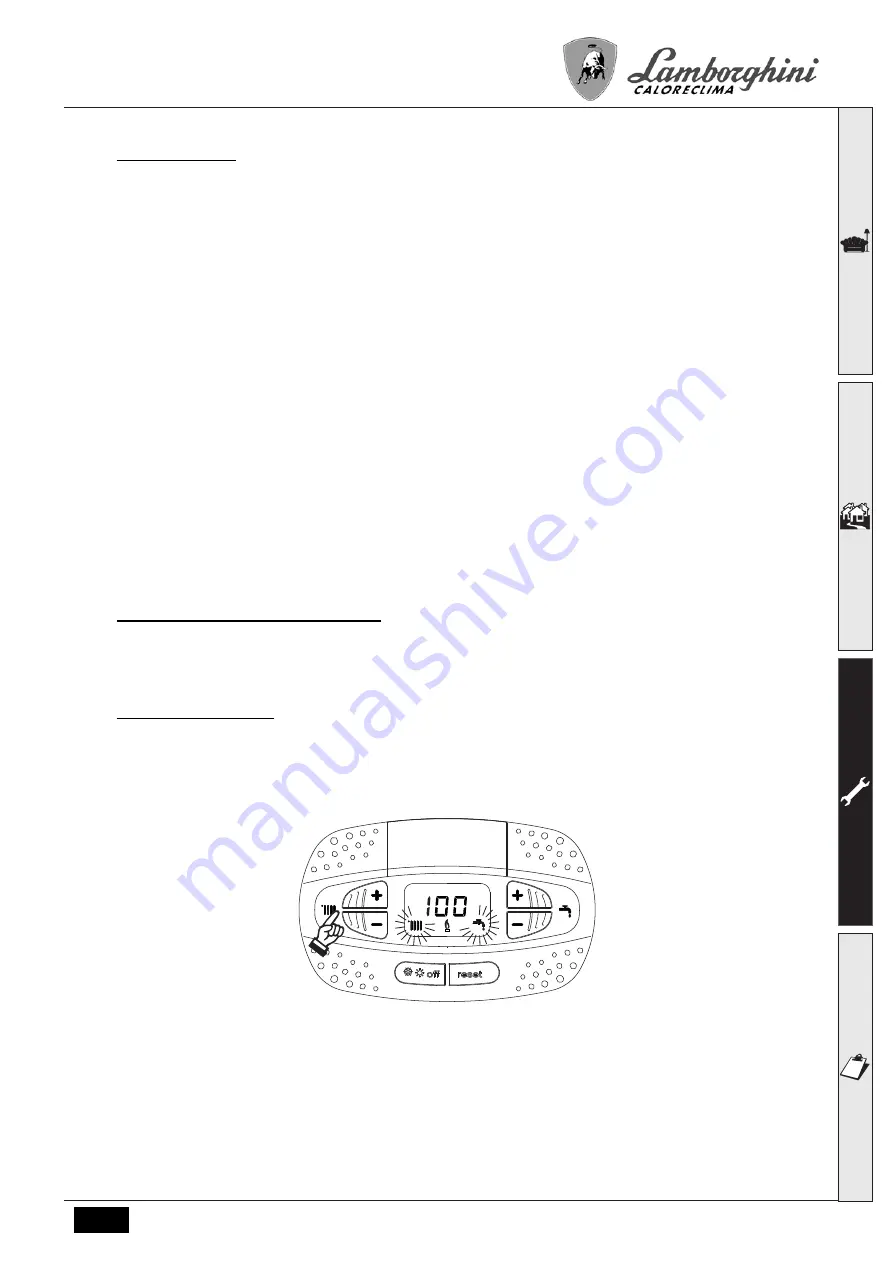

Press the heating buttons (detail 3 and 4 - fig. 1) together for 5 seconds to activate

TEST mode

. The boiler lights at the

maximum heating power set as described in the following section.

The heating and DHW symbols (fig. 32) flash on the display; the heating power will appear alongside.

fig. 32- TEST mode (heating power = 100%)

Press the heating buttons (details 3 and 4 - fig. 1) to increase or decrease the power (Minimum=0%, Maximum=100%).

By pressing the DHW

“-” button

(detail 1 - fig. 1), boiler output is immediately adjusted to minimum (0%).

Wait about 1 minute for stabilisation.

By pressing the DHW

“+” button

(detail 2 - fig. 1), boiler output is immediately adjusted to maximum (100%).

If the TEST mode is activated and enough hot water is drawn to activate the DHW mode, the boiler remains in TEST

mode but the 3-way valve goes to DHW.

To deactivate the TEST mode, press the heating buttons simultaneously (details 3 and 4 - fig. 1) for 5 seconds.