INSTALLATION

HYDRAULIC CONNECTION

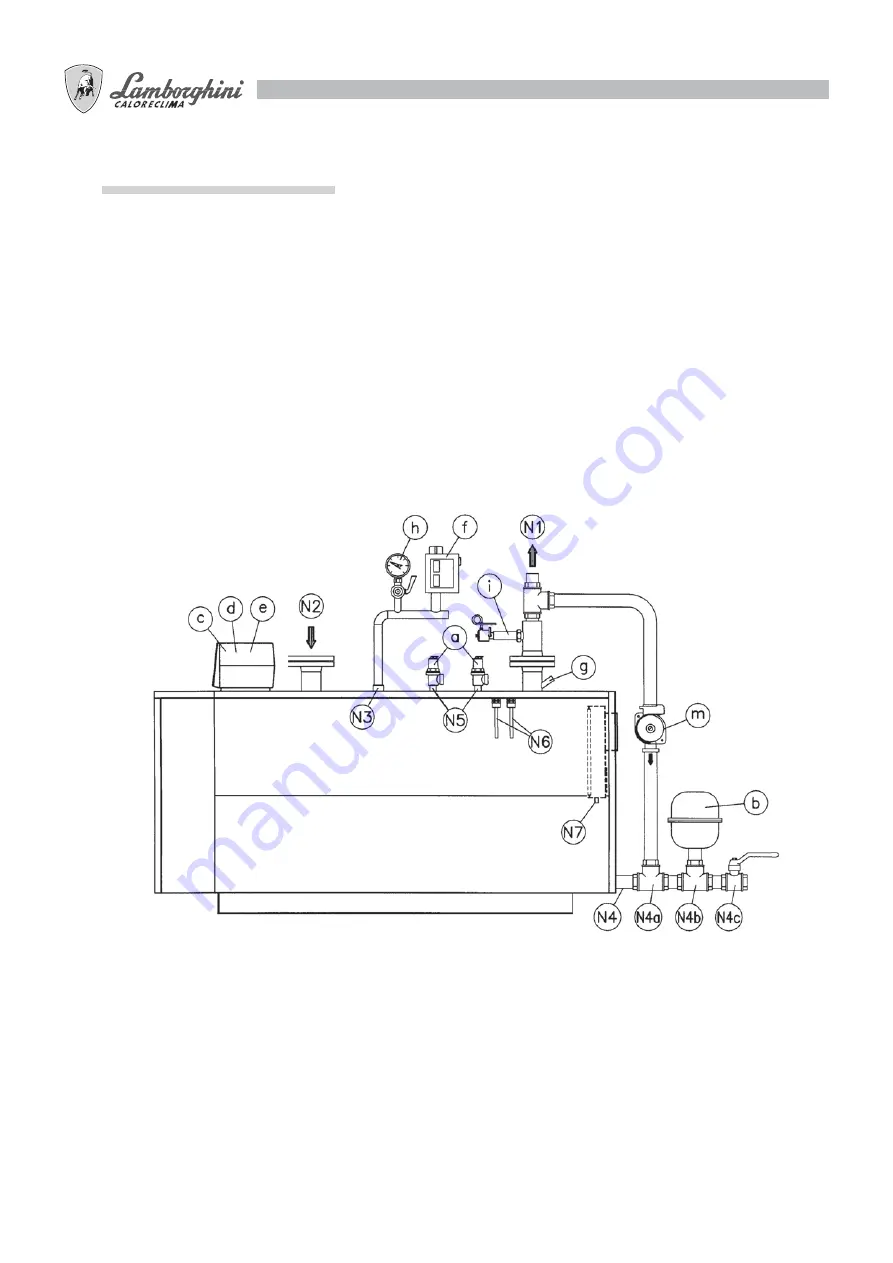

HOT WATER HEATING SYSTEM WITH CLOSED EXPANSION VESSEL

pressure 5 bar

Ensure that the hydraulic pressure measured after the reduction valve on the supply pipe does not exceed the operating

pressure specified on the rating plate of the component

(boiler, heater etc.).

- As the water contained in the heating system increases in pressure during operation, ensure that its maximum value does

not exceed the maximum hydraulic pressure specified on the component rating plate (5 bar).

- Ensure that the safety valve outlets of the boiler and hot water tank, if any, have been connected to an exhaust funnel in

order to prevent the valves from

flooding the room

if they open.

- Ensure that the pipes of the water and heating system

are not used as an earth connection

for the electrical system as

this can seriously and very rapidly damage the pipes, boiler, heater and radiators.

- Once the heating system has been filled, you are advised to close the supply cock and keep it closed so that

any leaks

from the system

will be identified by a drop in hydraulic pressure indicated on the system pressure gauge.

The generator must be provided with:

a

1 safety valve

2 safety valves if output is

(for MEGA PREX BT 580)

b

Expansion

vessel

c

Regulation

thermostats

d

1st safety thermostat

e

2nd safety thermostat

f

Cut-off pressure switch

g

Well for control thermometer

h

Pressure gauge with flange

for control pressure gauge

i

Heat discharge valve or fuel on-off valve

m

Recirculation

pump

N1

Flow

N2

Return

N3

Safety valve fitting (2 valves for MEGA PREX BT 580)

N4

Lower fitting:

N4a recirculation (anti-condensate pump)

N4b expansion vessel fitting

N4c

Filling/drain

N5

Instrument fitting

N6

Bulb wells (thermometer, pump consent thermostat,

regulation thermostat, safety thermostat)

N7

Condensation recollection fitting

- 20

-

Summary of Contents for MEGA PREX BT Series

Page 2: ...2 ITALIANO 3 ENGLISH 15 FRAN AISE 27 ESPA OL 39...

Page 51: ...51...