Taura 24 MCS W TOP

22

1.3 Turning on and off

Ignition

• Open the gas valve ahead of the boiler.

• Supply the unit with electricity.

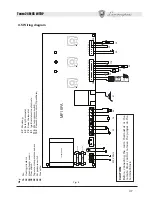

Turn the selector 3 onto

(winter) or onto

(summer)

• Turn the heating and hot water knob onto the required temperatures.

• The boiler is ready to function automatically whenever hot water is drawn or the room thermostat calls for heat-

ing.

If after the ignition cycle the burners fail to ignite and the red LED comes on, turn the selector onto RESET

for 1 second and then back onto

or onto

. The controller will repeat the ignition cycle in the next 30

seconds. If the burners fail to ignite even after the third attempt, refer to chap. 3.1.

In case of an electrical power failure while the boiler is working, the burners will go out and re-ignite auto-

matically when power is restored.

Turning off

Turn the selector onto 0.

When the boiler is turned off, the electronic card is still powered.

Hot water and heating operation are disabled, all the LEDs are off; but the antifreeze function stays on

The antifreeze system will not work if the electricity and/or gas supply to the unit are cut off.

To avoid damage caused by freezing during long shutdowns in winter, it is advisable to drain all water from

the boiler, the tap water and the system water; or drain off just the tap water and add a suitable antifreeze

to the heating system, as prescribed in chap. 2.3.

1.4 Adjustments

Water system pressure adjustment

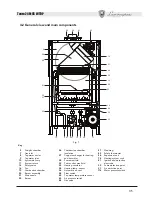

The filling pressure with the system cold, read on the boiler water gauge, must be about 1.0 - 1.5 bar. If the system

pressure falls to values below the minimum, bring it back to the initial value by operating the filling cock (see fig. 7

part 74). At the end of the operation always close the filling cock.

2. INSTALLATION

2.1 General Instructions

BOILER INSTALLATION MUST ONLY BE PERFORMED BY QUALIFIED PERSONNEL, IN ACCORDANCE WITH ALL

THE INSTRUCTIONS GIVEN IN THIS TECHNICAL MANUAL, THE PROVISIONS OF CURRENT LAW, THE PRESCRIP-

TIONS OF NATIONAL AND LOCAL STANDARDS AND THE RULES OF PROPER WORKMANSHIP.

2.2 Place of installation

The unit’s combustion circuit is sealed off from the installation room and therefore the unit can be installed in any

kind of room. However, the installation room must be sufficiently well ventilated to prevent any dangerous condi-

tions from forming in the event of even slight gas leakage. This safety standard is required by the EEC Directive no.

90/396 for all gas units, including those with a so-called sealed chamber.

Therefore the place of installation must be free of dust, flammable materials or objects or corrosive gases. The room

must be dry and not subject to freezing.

The boiler is fitted to be installed on a wall and is equipped as standard with a set of brackets. The LEJ LINE plumbing

kits also include a paper template to mark the drilling points on the wall if these kits are used. Secure the bracket to

the wall and hook on the boiler. The wall fixing must ensure a stable and effective support for the generator.