AXE 3 D UNIT 32 R HR

12

EN

cod. 3541B310 - 10/2011 (Rev. 00)

Turning the boiler off

Press the

on/off

button (detail 9 - fig. 1) for 1 second.

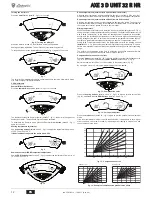

fig. 6 - Turning the boiler off

When the boiler is turned off, the electronic board is still powered.

Heating operation is disabled. The antifreeze system remains activated.

To relight the boiler, press the

on/off

button (detail 9 fig. 1) again for 1 second.

fig. 7

The boiler will be immediately ready to operate whenever domestic hot water is drawn

or in case of a room thermostat demand.

2.4 Adjustments

Summer/Winter Switchover

Press the

summer/winter

button (detail 6 - fig. 1) for 1 second.

fig. 8

The display activates the Summer symbol (detail 27 - fig. 1): the boiler will only deliver

domestic hot water. The antifreeze system remains activated.

To deactivate the Summer mode, press the Summer/Winter

button

(detail 6 - fig. 1)

again for 1 second.

Heating temperature adjustment

Use the

heating buttons

(details 3 and 4 - fig. 1) to adjust the temperature from a min.

of 30°C to a max. of 80°C.

It is advisable not to operate the boiler below 45°C

.

fig. 9

Domestic hot water (DHW) temperature adjustment

Use the

DHW buttons

(details 1 and 2 - fig. 1) to adjust the temperature from a min. of

10°C to a max. of 65°C.

fig. 10

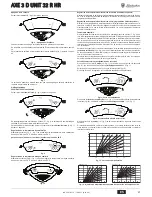

Room temperature adjustment (with optional room thermostat)

Using the room thermostat, set the temperature desired in the rooms. If the room ther-

mostat is not installed the boiler will keep the heating system at its setpoint temperature.

Room temperature adjustment (with optional remote timer control)

Using the remote timer control, set the temperature desired in the rooms. The boiler unit

will set the system water according to the required room temperature. For information on

the remote timer control, please refer to its user's manual.

Sliding temperature

When the optional external probe is installed, the control panel display (detail 5 - fig. 1)

shows the actual outside temperature read by the probe. The boiler control system works

with "Sliding Temperature". In this mode, the heating system temperature is controlled

according to the outside weather conditions in order to ensure high comfort and energy

saving throughout the year. In particular, as the outside temperature increases the sys-

tem delivery temperature decreases according to a specific "compensation curve".

With Sliding Temperature adjustment, the temperature set with the heating buttons

(details

3 and 4 - fig. 1) becomes the maximum system delivery temperature. It is advis-

able to set a maximum value to allow system adjustment throughout its useful operating

range.

The boiler must be adjusted at the time of installation by qualified personnel. Adjust-

ments can in any case be made by the user to improve comfort .

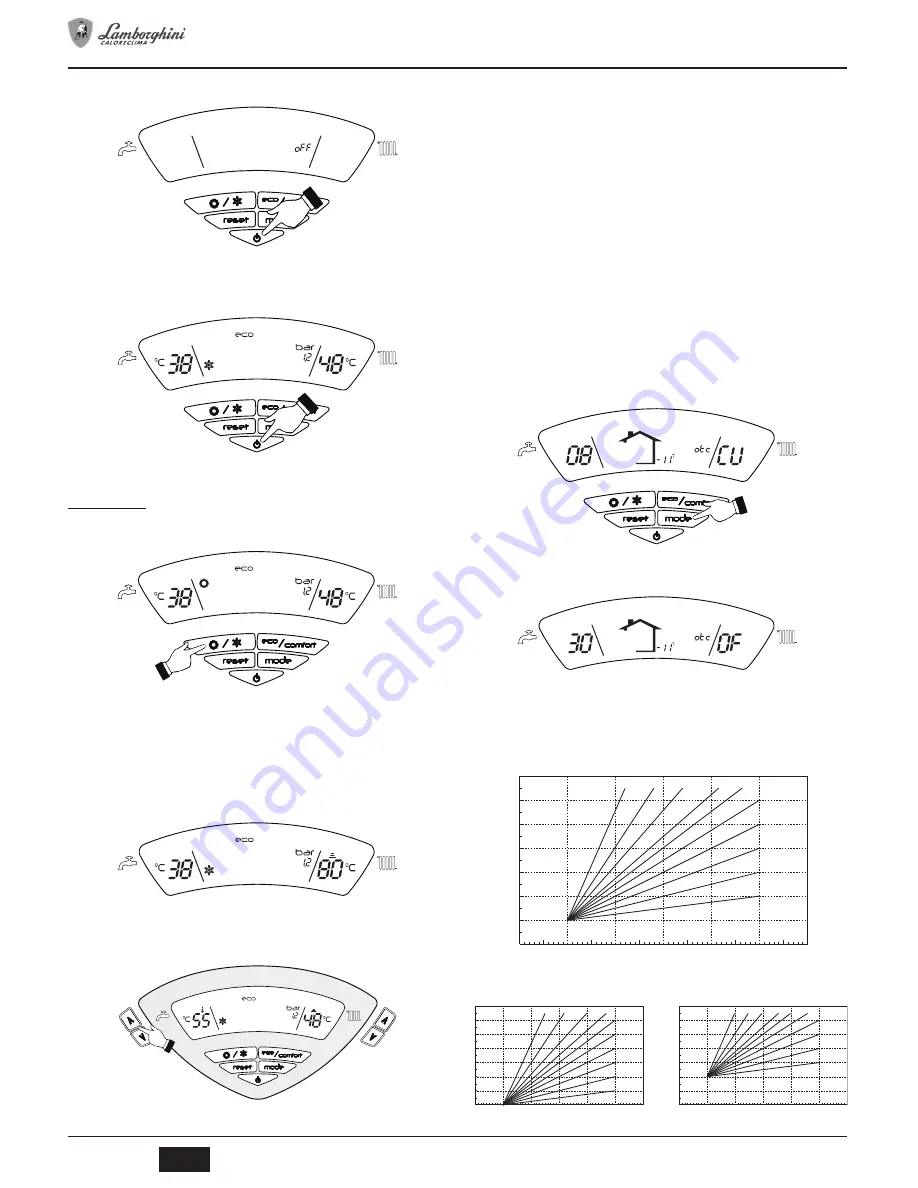

Compensation curve and curve offset

Press the

mode

button (detail 10 - fig. 1) once to display the actual compensation curve

(fig. 11) which can be modified with the

DHW buttons

(details 1 and 2 - fig. 1).

Adjust the required curve from 1 to 10 according to the characteristic (fig. 13).

By setting the curve to 0, sliding temperature adjustment is disabled.

fig. 11 - Compensation curve

Press the

heating buttons

(details 3 and 4 - fig. 1) to access parallel curve offset

(fig. 14), modifiable with the

DHW buttons

(details 1 and 2 - fig. 1).

fig. 12 - Curve parallel offset

Press the

mode

button (detail 10 - fig. 1) again to exit the parallel curve adjustment

mode.

If the room temperature is lower than the required value, it is advisable to set a higher

order curve and vice versa. Proceed by increasing or decreasing in steps of one and

check the result in the room.

fig. 13 - Compensation curves

fig. 14 - Example of compensation parallel curve offset

IIIIIIIIIIIII

IIIIII

I

IIII

IIIIIIIIII

IIIIII

IIII

IIIII

III III

IIIIIIIIIIIII

IIIIIIIIIIIIIIIIII

IIIIII

IIIIII

IIIII

IIII

I

IIIIIIIIIIIIIIIIII

IIIII

IIIIIII

IIIII

IIII

I

20

30

40

50

60

70

80

90

85

20

10

0

-10

-20

1

2

3

4

5

6

8

9

10

7

20

30

40

50

60

70

80

90

85

20

10

0

-10

-20

1

2

3

4

5

6

8

9

10

7

20

10

0

-10

-20

20

30

40

50

60

70

80

90

85

1

2

3

4

5

6

8

9

10

7

OFFSET = 20

OFFSET = 40

Summary of Contents for AXE 3 D UNIT 32 R HR

Page 31: ......