EN

59

cod. 3541S870 - Rev. 03 - 07/2020

JEREZ ECO

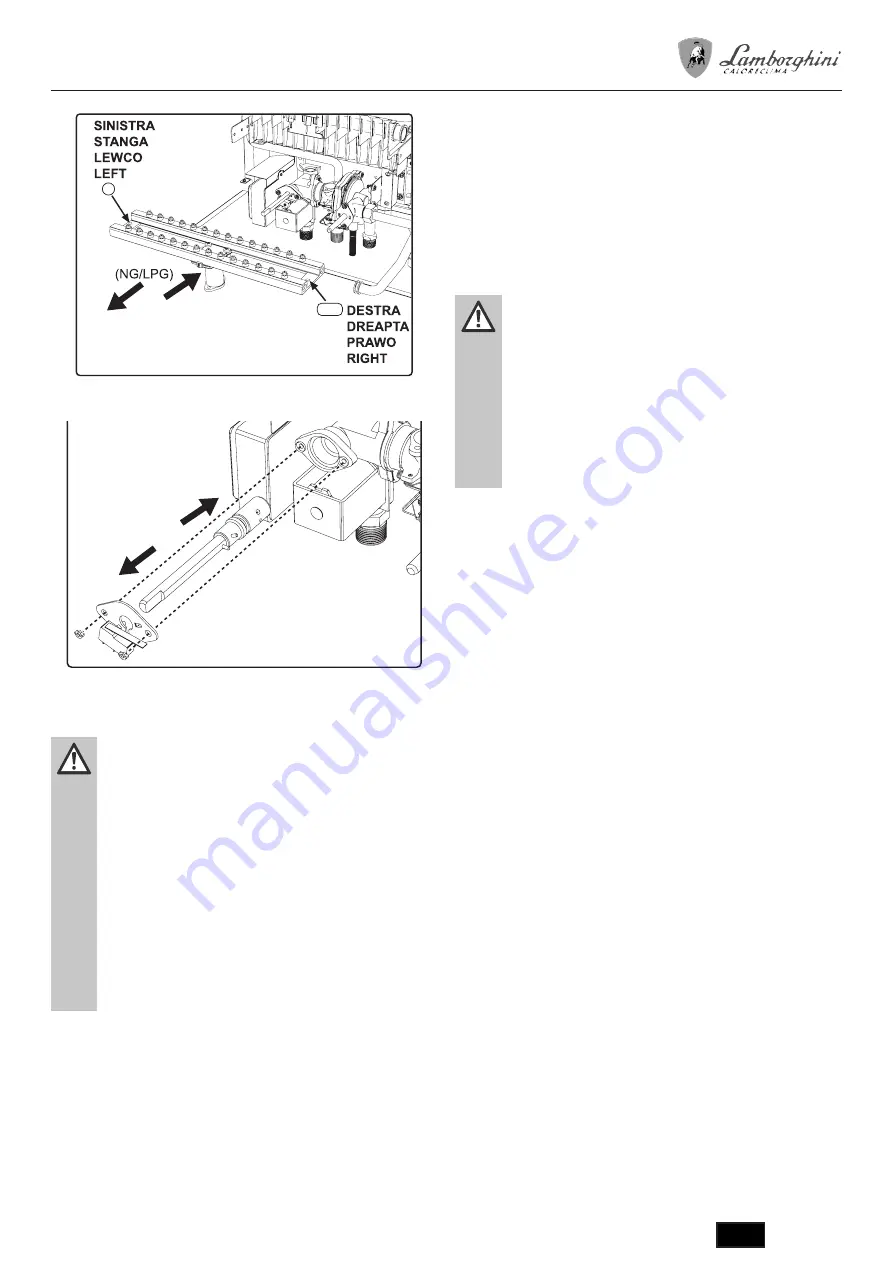

fig. 14 -

fig. 15 -

3.2 COMMISSIONING

Commissioning of the heater

must be performed by a trained,

specialized technician.

Checks that must be performed

during the first ignition, after

maintenance operations that

require unplugging the unit,

and after any operations on the

unit's safety devices or compo-

nents.

3.2.1 Before igniting the heater

•

Carefully verify the tightness of the gas installation

using a soap and water solution to check for leaks in

the connections.

•

Fill the hydraulic system and make sure no air is pre-

sent in the unit or system.

•

Check that there are no water leaks in the system or

unit.

•

Make sure the grounding and connection to the electri-

cal network are adequate.

•

Check that the gas pressure is correct.

• Make sure there are no flammable liquids or materials

near the heater.

•

To avoid damaging the connections, do not place the

heater on the floor with the connections facing down.

If the above instructions are not

observed there may be risk of

suffocation or poisoning due to

gas or fumes escaping; danger

of fire or explosion. Also, the

-

re may be risk of flooding the

room.

3.2.2 Checks during operation

• Light the unit.

• Make sure the fuel and water systems are tight.

• Check the efficiency of the air and flue gas ducts while

the heater is operating.

• Make sure the gas valve modulates correctly.

• Verify that the heater ignites easily. Turn it on and off

several times to make sure.

• Check that the fuel consumption is as indicated.

3.3 MAINTENANCE

3.3.1 Periodic checks

In order for the unit to operate correctly, an authorized

technician must perform an annual inspection, checking

that:

•

The control and safety devices (gas valve, etc.) opera-

te correctly.

• The exhaust vent is perfectly efficient.

• The air and flue gas ducts and terminal are free of ob

-

stacles and leaks.

•

The burner and exchanger are free of dirt and deposits.

Do not use chemicals or steel brushes to clean them.

•

The electrode is free of deposits and properly positio-

ned.