48

Once the connections have been made power up the boiler and, after the “

CON

” signal, check that the legend

“

OFF

” appears on the main display and that the time 00:00 on the lower display and the day indicator both

appear

.

If the legend “

CON

” persists this indicates improper connection of the control unit to the boiler.

NOTE:

In the event of a power failure the control unit will memorise the data for up to 24 hours.

SETTING THE TIME/DAY OF THE WEEK

You can set the clock time and the day of the week in any mode.

To begin setting press the

H/Day

key once.

The minute figures will then start flashing.

Press the

+

and

–

keys to set the minutes and then press

H/Day

again to confirm.

The hour figures on the display will now flash.

Press the

+

and

–

keys to set the hour and then press

H/day

again to confirm.

Once you have completed setting the clock time the day indicator

will begin flashing.

The

indicators signal the sequence of days from Monday to Sunday (1 = Monday, 2 = Tuesday etc.)

Press the

+

and

–

keys to select the desired day then press

P

to memorise the settings.

MODES

The control unit runs the boiler by enabling or disabling each individual mode according to requirements.

Press the

key repeatedly and the following modes will be enabled in sequence: OFF, Hot water, Hot

water/Heating and Heating.

●

OFF MODE (“OFF” APPEARS ON THE DISPLAY)

This mode allows you to disable the Hot water and Heating functions, yet keeps the boiler safety functions

operative.

In this mode any request for hot water and any request to switch on the heating circuit will be ignored.

●

“HOT WATER” MODE (

SYMBOL DISPLAYED)

This function enables the boiler for production of hot water.

When this function is enabled it is possible to adjust the hot water to the desired temperature.

In this mode, any request to switch on the heating circuit will be ignored.

89

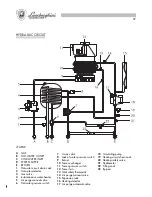

ENCENDIDO

LLENADO DE LA INSTALACIÓN

Abrir lentamente el grifo de alimentación (

1

) hasta llevar la presión de la

instalación, indicada por el hidrómetro (

2

) al valor 1,5, a continuación volver

a cerrarlo. Verificar que la válvula de tres vías (

3

) esté en posición manual,

que la válvula de seguridad automática (

4

) situada en el circulador tenga el

capuchón aflojado y funcione normalmente, a continuación mediante una

válvula manual (

5

) situada en el calentador, hacer salir el eventual aire. Antes

del encendido, asegurarse de que la presión del agua en la instalación no

haya descendido por debajo del valor inicial de carga. Para un mejor

funcionamiento de la caldera mantener siempre la presión de la instalación

en valores no inferiores a 1,5 bar.

ENCENDIDO

Abrir el grifo del gas. Activar el interruptor general de alimentación eléctrica

situada en la pared. Seleccionar en el mando remoto la función deseada

(verano/invierno/apagado) visualizando la función con los específicos

indicadores.

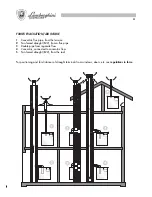

INSTALACIÓN

Tiene que realizarla el personal técnico cualificado.

La instalación deberá ser conforme a las disposiciones de ley concernientes la evacuación de los productos de

la combustión según las NORMAS VIGENTES. Es obligatorio que la evacuación de los gases combustibles se

efectúe con tubo de diámetro no inferior al predispuesto en la caldera y que se empalme a un conducto de

humos, adecuado a la potencialidad de la instalación.

Les recordamos también algunos de los principales requisitos de unión entre los aparatos y los conductos de

humos:

a

) ser fácilmente desmontables;

b

) ser herméticos y de material adecuado para resistir a los productos de la combustión y a sus eventuales

condensaciones;

c

) no tener dispositivos de regulación (registros). Si tales dispositivos existieran ya, deberán ser eliminados;

d

) No debe sobresalir el interior del conducto de humos, hay que pararse antes de la cara interna de éste.

CONEXIÓN GAS

Efectúen la conexión del gas según la normativa vigente.

Hay que unir la caldera a la instalación con un tubo metálico rígido, o con tubo flexible de acero inoxidable

de pared continua y de tipo homologado. Los tubos flexibles metálicos ondulados hay que utilizarlos de

manera que su longitud, en condiciones de máxima extensión, no sea mayor de 2000 mm. Las calderas están

reguladas y probadas para funcionar con GAS NATURAL y GAS LÍQUIDO de la categoría II 2H3+, a una

presión nominal respectivamente de 20 mbar,28/30 mbar y 37 mbar.

PUESTA EN FUNCIONAMIENTO DE LA INSTALACIÓN

●

Procedan a la purga de aire.

●

Controlen que no haya escapes de gas (usen una solución

jabonosa o un producto equivalente).

Summary of Contents for thin 24 MCS W TOP U/IT

Page 3: ......

Page 5: ......

Page 7: ......

Page 9: ......

Page 11: ......

Page 13: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 23: ......

Page 25: ......

Page 27: ......

Page 29: ......

Page 31: ......

Page 33: ......

Page 35: ......

Page 37: ......

Page 39: ......

Page 41: ......

Page 43: ......

Page 45: ......

Page 47: ......