54

INSTALLER SETTINGS

The tasks in this section must only be carried out by qualified personnel.

Carrying out these procedures wrongly may damage the control unit and boiler or cause them to malfunction.

●

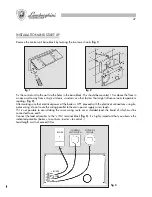

CONNECTING UP TO THE OUTDOOR TEMPERATURE SENSOR.

The control unit can also be fitted with a sensor that monitors outdoor temperature.

The outdoor temperature reading utilised by the control unit may be supplied in one of two different ways:

-

when the outdoor temperature sensor is connected to the boiler the temperature reading is sent from

the boiler to the control unit.

-

when the outdoor temperature sensor is connected directly to the control unit the reading is acquired

and processed by the control unit directly.

If both are present the local sensor is ignored and the outdoor sensor connected to the boiler base is

utilised.

This situation is highlighted by the appearance of error message

E67

.

To connect the outdoor sensor to the control unit use the S.EXT connection on the terminal block.

With the outdoor sensor connected, pressing the

key shows the outdoor temperature and heating

water temperature.

●

ENABLING REMOTE OPERATION

The control unit has an input (

TEL

+

and

-

) which allows connection of an optional control unit for distance

operation.

Operating mode:

-

TEL

input open

The control unit operates as described in the handbook.

-

TEL

input closed

The control unit switches to remote mode, that is:

heating and hot water functions enabled, automatic temperature regulation according to timer programme

with on-display information while upper display shows the

TEL

message in place of room temperature.

This mode persists until the user disables it by acting on the remote mode switch (

TEL

input open). Standard

operating mode is then restored.

●

CLOCK SPEED CORRECTION

Allows you to improve clock precision by increasing speed (should it run slow) or decreasing speed

(should it run fast).

The entire correction procedure must be done with the control unit powered and connected to the boiler.

Clock correction:

Press key

R

and keep it pressed.

Press the

H/Day

key

Release the

R

key and wait for the display to show the “

Hour

” confirmation message.

The next two stages must be done within 5 seconds otherwise the procedure will be aborted (a change of

one unit alters clock speed by 30 seconds a year).

Release the

H/day

key.

Press the

+

key to increase clock speed (an increase of one unit speeds up the clock by 30 seconds a year).

Press the

–

key to reduce clock speed (a decrease of one unit slows down the clock by 30 seconds a year).

Wait 5 seconds after the last modification to exit this function and recommence normal operation.

83

Para programarla presione el botón

; en la pantalla aparecerá la temperatura actualmente

programada.

Manteniendo presionado el botón

, presione los b y - para programar la temperatura

deseada.

Soltando el botón

la programación será memorizada.

●

TEMPERATURA AMBIENTE REDUCIDA

La programación de esta temperatura se realiza con la función “calefacción” o “circ. sanitario/calefacción”

activada.

Para programarla presione el botón

; en la pantalla aparecerá la temperatura actualmente

programada.

Manteniendo presionado el botón

, presione los botones

+

y

-

para programar la temperatura

deseada.

Soltando el botón

la programación será memorizada.

VISUALIZACIÓN DE LOS PARÁMETROS Y ESTADO DE LA CALDERA

Presionando varias veces el botón se pueden visualizar, en la secuencia abajo indicada, los parámetros

principales de la caldera.

Parámetros visualizados:

-

Temperatura efectiva del agua de calefacción (símbolo

intermitente)

-

Temperatura efectiva del agua caliente sanitaria (símbolo

intermitente)

-

Temperatura ambiente programada en base al nivel actual (símbolo

intermitente)

-

Temperatura externa (símbolo

intermitente)

Si no hay una sonda externa la pantalla indica “

—:—

“

-

Presión del agua en la instalación (símbolo

intermitente)

Si no hay un presostato para el agua la pantalla indica “

—:—

“

El símbolo encendido indica que está funcionando el “circ. sanitario” o la “calefacción”.

Summary of Contents for thin 24 MCS W TOP U/IT

Page 3: ......

Page 5: ......

Page 7: ......

Page 9: ......

Page 11: ......

Page 13: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 23: ......

Page 25: ......

Page 27: ......

Page 29: ......

Page 31: ......

Page 33: ......

Page 35: ......

Page 37: ......

Page 39: ......

Page 41: ......

Page 43: ......

Page 45: ......

Page 47: ......