23

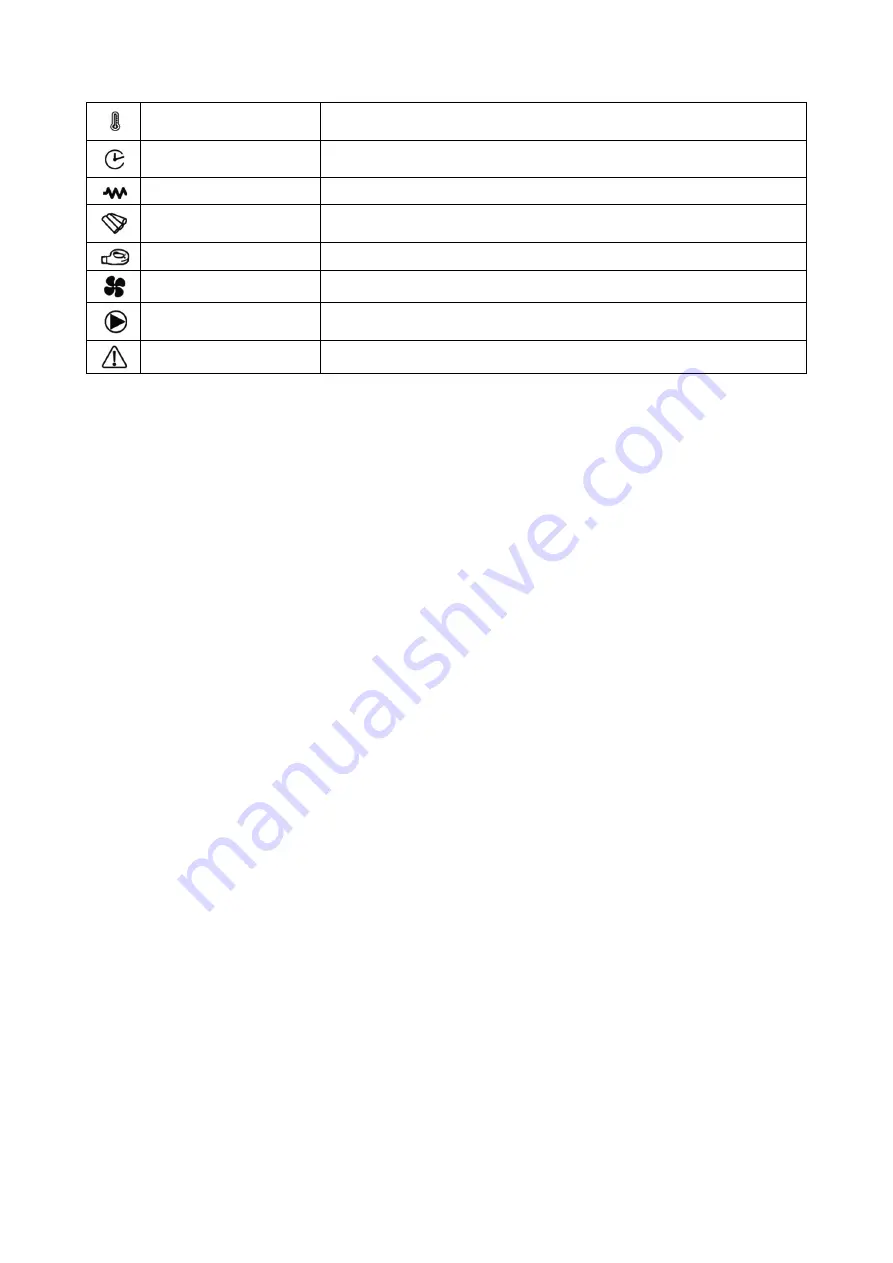

Below is a list of meanings of LEDs found on control panels:

Room thermostat LED

The LED is on when it is connected to an external room thermostat and it is

closed.

Chrono LED

The LED switches on when the programmable thermostat is activated;

meaning, if user parameter 03-01-01 enables chrono, it is different from off.

Glow plug LED

The LED switches on when the glow plug is powered.

Feed screw on LED

The LED switches on in the time intervals in which the pellet feed screw is in

operation.

Smoke fan LED

The LED switches on when the smoke fan is on.

Exchanger LED

The LED switches on when the fan is in operation (air version)

Pump on LED

The LED switches on when the pump/circulator is in operation (only with

Hydro and boiler models)

Alarms LED

The LED switches on when there is an alarm activated on the stove.

6.2 First ignition

Before igniting the stove, you MUST have a qualified technician perform "FIRST START-UP" and calibration.

For this purpose, we advise you to contact personnel part of our network of authorised service centres.

The company assumes no responsibility for malfunctions due to improper installation, failure to

install, incorrect first ignition, or improper use.

Make sure that electrical and plumbing connections have been performed properly. Also check that the

hydraulic system (on heating stoves and boilers) has a sufficient expansion tank for maximum safety. Please

note that expansion is calculated considering 10% of the whole volume contained in the system. Any damage

to the system or to equipment will not be considered under warranty. The presence of the tank fitted on the

unit does not guarantee adequate protection against sustained thermal expansion of the system water.

Fill up the system through a refill valve (to be provided externally to the stove). During recovery, it is advisable

not to exceed a maximum pressure of 1 bar. Pressure can be read directly on the pressure gauge (item 7

par. 5.5).

The water loading phase should be simultaneous to air exhaust.

Before lighting the stove, also check that the brazier is pushed back towards the rear wall of the

combustion chamber.

The first few times you light the stove, it may give off odours due to the evaporation of paint or grease. Simply

ventilate the room to make the odour go away, avoiding prolonged exposure as vapours can be harmful to

people or animals. Do not allow children to stay in the room during this first phase.

When the tank is loaded for the first time, the feed screw must fill up for a given period. During this time, pellets

will not be distributed within the combustion chamber. To overcome this difficulty, use the command "initial

load" in menu 7 of the control panel (see further details to follow).

6.3 Ignition and normal operation

Before igniting the stove:

•

Check that the furnace door is locked.

•

Make sure that the pellet tank is full or contains such enough so that the stove will function for the desired

amount of time.

•

Make sure that the brazier is clean, free of ashes, combustion residue or unburned pellets (if necessary,

remove the brazier and thoroughly clean it, then replace it with care in its housing). In the event or start-

up with the programmable thermostat, make sure that the brazier is in the indicated conditions after last

use.

When the stove is connected to the electrical system but not in work mode, the display will show the message

"OFF".

6.3.1 Stove start-up

To start up the stove, hold and press the start button (4) for 2 seconds

If you start the stove during the final cleaning phase, the display may show the message "WAIT COOLING."

In this case, wait for a minute before retrying ignition.