15

o

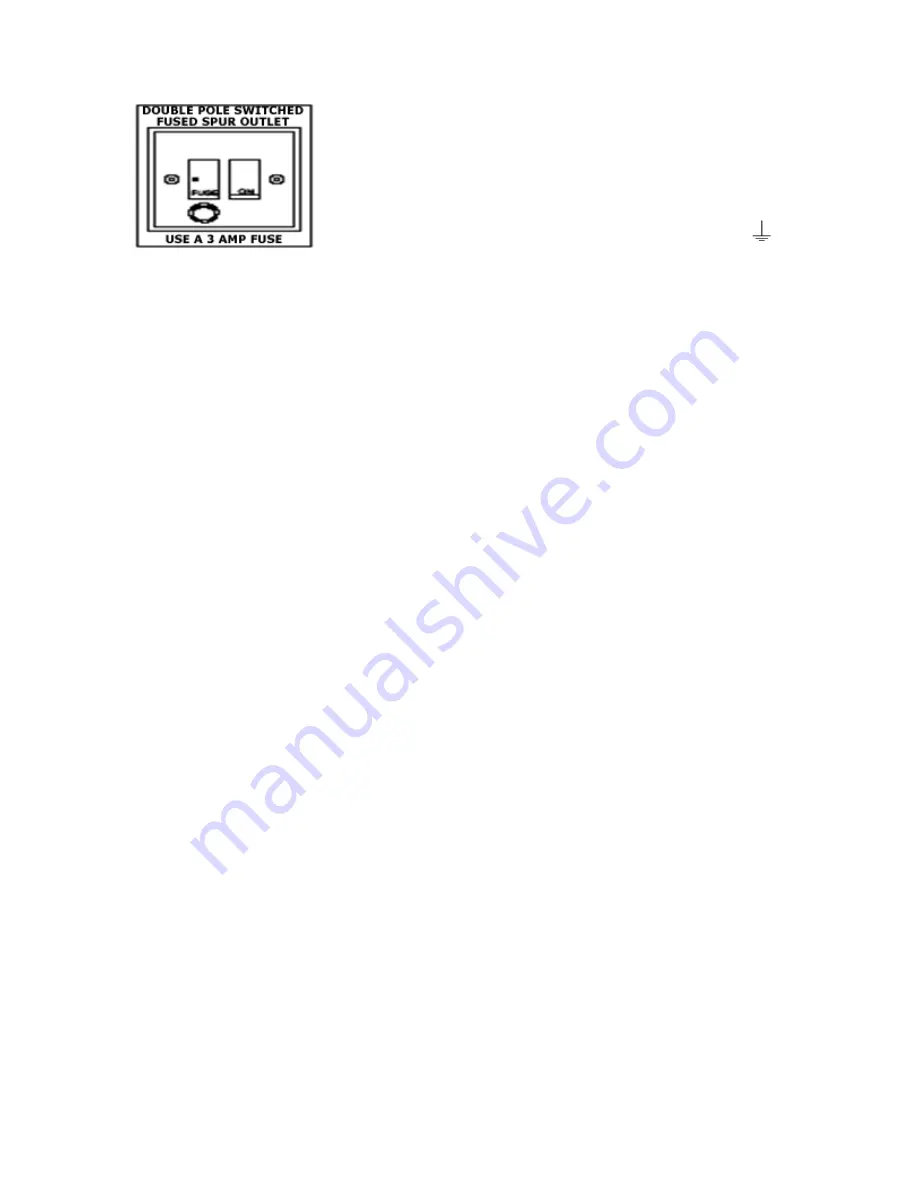

As the colours of the wires in the appliance’s mains lead may not

correspond with the coloured markings identifying the terminals

in your spur box, please proceed as follows:

o

The

blue wire

must be connected to the

terminal marked “N” (neutral), or

black

.

o

The

brown wire

must be connected to the

terminal marked “L” (live), or

red

.

o

The

green/yellow

wire

must

be

connected to the terminal marked “ “

(earth) or

green

.

Before beginning installation

o

Check that the product purchased is of a suitable size for the

chosen installation area. In addition check whether there is an

electrical socket available that will be accessible once the

extractor is mounted. If the product is going to be used in

extraction mode, then there should also be space to connect a

ducting hose to the outside.

o

Carry out all necessary masonry work prior to the fitting of the

extractor.

o

Ensure that all electrical connections are carried out by a suitably

qualified person.

o

Before commencing installation of the extractor the grease filters

should be removed.

o

Check inside the product and insure that there is no transit

packaging or any other materials, such as packets of screws,

guarantees etc. These should be removed and kept for future

use.

o

If possible, disconnect and move freestanding or slot-in cookers

from their position, to provide easier access to the rear wall and

ceiling. If this is not possible, then a thick, protective covering

should be placed over the worktop, hob top or cooker. This will

help to protect these surfaces from damage and debris.

o

Select a flat surface for assembling the extractor. Cover that

surface with a protective covering and place all parts and fittings

on to it.

o

Rawl plugs are provided to secure the extractor to most types of

walls and ceilings. However a qualified technician must verify the

suitability of the materials, in accordance with the type of wall

Summary of Contents for HJA2480

Page 24: ...24 Your Guarantee...

Page 25: ...25...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28...