11

USER MANUAL

Use the button in the bottom left corner to return to the home screen. Use the arrow button in the bottom right corner to return to previous screen.

For instructions screen, press the ‘i’ button in the top right corner. In case of operation faults, an alarm button is displayed on the top bar.

water-related hazards. In general, the compressor is controlled according

to the minimum setting of the storage tank lower part.

In summer, when there is no need for heating (with the exception of

humid rooms), the compressor is seldom on and there is less superheat

-

ing for domestic hot water production. In such a case the storage tank

upper part and lower part temperatures are close to each other.

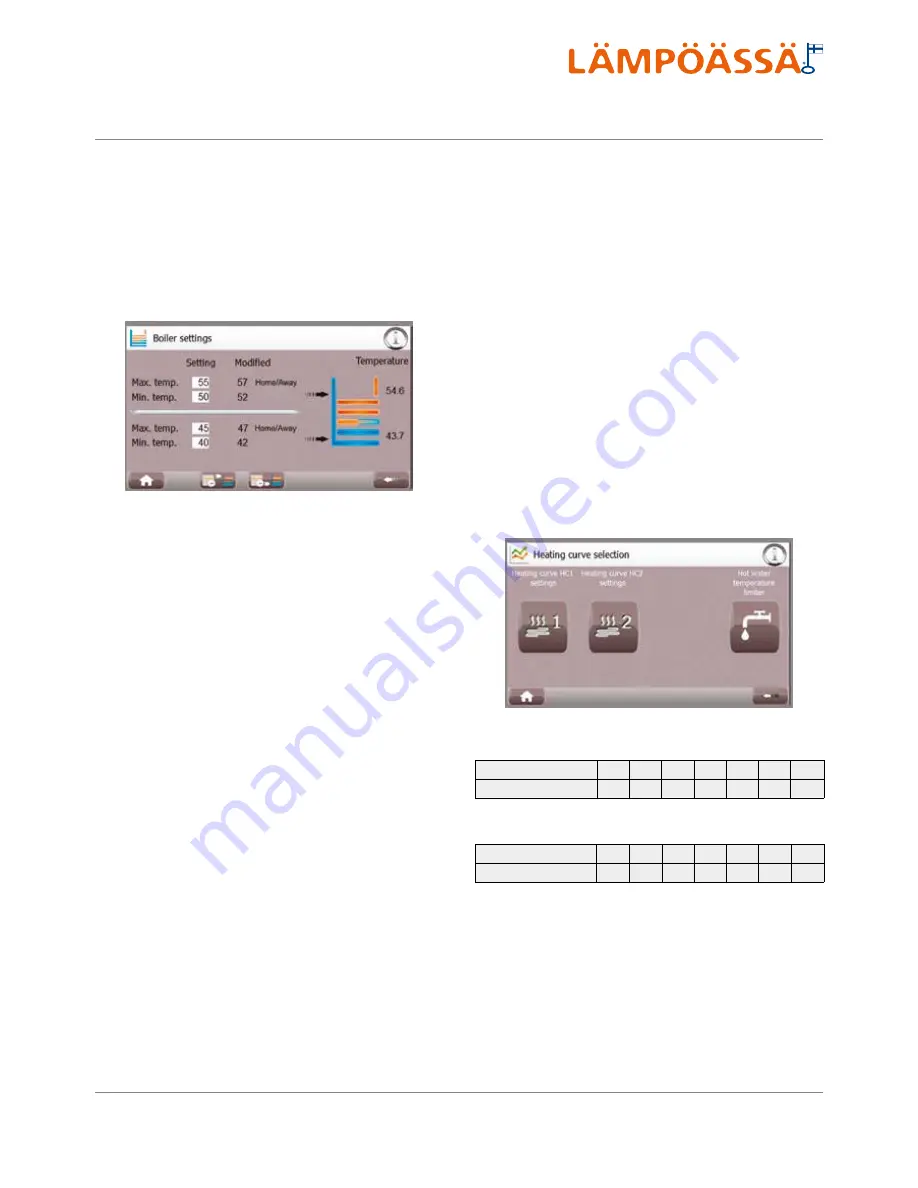

3.5.2. Adjustment curves

Heat distribution circuits (HD) are controlled by a seven-point adjust

-

ment curve. Depending on the connections, the control system controls

1-3 heat distribution circuits or 1-2 heat distribution circuits and domes

-

tic hot water temperature. In the Adjustment curves menu, the values of

all heat distribution circuits can be changed separately to meet the heat

-

ing water temperature (supply water) at a certain outdoor temperature.

Exemplary floor heating adjustment curve (factory setting) °C*

Outdoor temperature

-20

-13

-7

0

+7

+13

+20

Heating water temperature

+32

+31

+29

+27

+25

+23

+21

Exemplary radiator heating adjustment curve °C*

Outdoor temperature

-20

-13

-7

0

+7

+13

+20

Heating water tempe53

+48

+42 +36 +30 +25

+21

The factory-set adjustment curve is suitable for floor heating. The adjust

-

ment curve values should be specified during the first year; they could be

changed as follows, for example: If the indoor temperature feels too chilly

while the outdoor temperature is -10 °C, the supply water set value can

be increased a little at the outdoor temperature points -13 °C and -7 °C.

Monitor the influence of the adjustment on room temperature for at least

24 hours before making any further modifications in adjustment curve

set values. When using radiator heating temperature change is quicker.

* Conditions in Finland.

pumps and 60 °C (bottom section) / 85 °C (top section) in case of part-

power geothermal heat pumps.

The value Correction indicates the temperature as corrected by the Timer

function, Home/Away function, Domestic water boost function, or auto

-

matic heat distribution circuit correction.

The storage tank temperature is a decisive factor in compressor starting

and stopping. The minimum value programs compressor starting at the

storage tank’s target temperature. The maximum value programs com

-

pressor stopping at the storage tank’s target temperature.

The storage tank is heated by the compressor. If the target temperature

cannot be reached in a certain time (1...24 h), it is presumed that there

is something wrong with the compressor and the compressor is turned

off. In such cases, the storage tank is heated by the electric heating ele

-

ment. The default set value for this function is 12 h. If the electric heat

-

ing element is switched on, the following warning is displayed on the

control panel display: Storage tank temperature not achieved in set time.

Electric heating element has been switched on. For more information on

programming the time, see menu Set values. NOTE! Electric heating is

used only as back-up!

Maximum annual ground source heat pump efficiency can be achieved if

the storage tank temperature is kept at an optimal level. The ground rule

is that the storage tank set values must be kept at the lowest possible

level, since it allows the best annual efficiency.

In winter, when the need for heating is larger, the set value for the storage

tank bottom section should be programmed in relation to the supply

water temperature. The temperature of the storage tank upper part

increases after a long period of use and the threshold value for the com

-

pressor to run is 90 °C. This is due to the superheating properties of the

storage tank structure. Because of this, the domestic hot water tempera

-

ture limiting function (option) can be used in order to avoid potential hot

Summary of Contents for VMI 6-17

Page 1: ...L MP SS Vmi 6 17 L MP SS 3 2016 INSTRUCTIONS FOR USE INSTALLATION AND MAINTENANCE...

Page 31: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 6 38 dB 00 dB 8 kW 8 kW 8 kW...

Page 32: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 6...

Page 35: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 9 41 dB 00 dB 10 kW 10 kW 10 kW...

Page 36: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 9...

Page 39: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 11 36 dB 00 dB 11 kW 11 kW 11 kW...

Page 40: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11...

Page 44: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11 1x230V...

Page 47: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 14 38 dB 00 dB 14 kW 14 kW 14 kW...

Page 48: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14...

Page 52: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14 1x230V...

Page 55: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 17 42 dB 00 dB 17 kW 17 kW 17 kW...

Page 56: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 17...

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......