17

17

INSTALLER MANUAL

10. When de-aeration has been completed turn the motor protection

switch QM1 off and also manual control function off.

11. Open shut-off valve (1) at the back of the group of fill valves.

12. Close both ball valves (3) and (4).

13. Remove the fill hoses.

14. Fasten the expansion vessel back in its place in the foremost ball

valve (3) in the group of fill valves.

15. Remove the safety valve on the expansion vessel.

16. Fill ¾ of the expansion vessel with water/ethanol or water/glycol

mixture.

17. Fasten the safety valve to the expansion vessel.

18. Open the foremost shut-off valve (3) in the group of fill valves.

19. Remove and clean the net strainer (5) on the mud separator,

repeat this several times, if necessary. The red-handled valves (1)

and (2), as well as the valve under the fill container (3) must be

closed in order to prevent fluids from running out.

Filling and de-aeration have now been completed.

4.2.3. Heating and domestic

hot water connections

Remove the crown panel from the

geothermal heat pump’s upper part

for the duration of installation works

by undoing the two screws shown in

the picture. Pull the crown panel directly forward and lift it off the heat

pump. Make the heat distribution and domestic water connections as

shown in the picture below.

1

2

3

4

5 6

7

8

10

9

11

12

13

1. Lämmönjako 1, meno

Heating flow 1

22 mm

2. Lämmönjako 1, paluu Heating return 1

22 mm

3. Lämmönjako 2, meno

Heating flow 2

22 mm

4. Lämmönjako 2, paluu Heating return 2

22 mm

5. Kylmä vesi

Cold water

22 mm

6. Lämmin vesi

DHW flow

22 mm

7. Paisunta

Expansion

¾”

8. Maapiiri, meno

Collector circuit, flow

1”

9. Maapiiri, paluu

Collector circuit, return

1”

10. Jäähdytys, meno

Cooling, flow

1”

11. Jäähdytys, paluu

Cooling, return

1”

12. Aurinkoyhde, meno

Solar connection, flow

¾”

13. Aurinkoyhde, paluu

Solar connection, return ¾”

14. Kv-kierto

Hot water circulation

½”

Varaajan täytön yhteydessä varaajassa olevan ilman on päästävä vapaasti

poistumaan. Huom! Ei ilmaventtiilin tai varoventtiilin kautta.

While filling the storage tank outgoing air has to be freely deflated.

NB! Not via air valve or safety valve.

14

Heating connection

Heat distribution circuit surface sensors located on top of the storage tank

must be installed to the distance of approx. 0.5 m from the three-way or

four-way valve. Circuit HD1 is always the main heating circuit (rooms, for

example); it is used for higher temperature (radiator heating, for example). In

case of compressor malfunction, the electric heating element heats the cir

-

cuit HD1 more efficiently. Circuit HD2 is used in radiator-heated buildings for

the possible floor heating share or for other purposes (e.g., humid rooms).

Speed controlling of the heat circulation pumps

Grundfos UPM3 AUTO heat circulation pump which is used in a HD cir

-

cuit can be set in three different controlling modes: proportional pressure

mode, constant pressure mode, constant curve mode.

Factory setting is

proportional pressure mode 3.

In radiator network constant pressure

mode 1 or 2 can be used if sound of the flow water is disturbingly high.

Proportional pressure mode

LED1

green

LED2

yellow

LED3

yellow

LED4

yellow

LED5

yellow

Proportional pressure mode 1

Proportional pressure mode 2

Proportional pressure mode 3

Auto

Adapt

Constant pressure mode

LED1

green

LED2

yellow

LED3

yellow

LED4

yellow

LED5

yellow

Constant pressure mode 1

Constant pressure mode 2

Constant pressure mode 3

Auto

Adapt

Constant curve mode

LED1

green

LED2

yellow

LED3

yellow

LED4

yellow

LED5

yellow

Constant curve mode 1

Constant curve mode 2

Constant curve mode 3

Constant curve mode 4

Summary of Contents for VMI 6-17

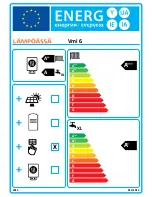

Page 1: ...L MP SS Vmi 6 17 L MP SS 3 2016 INSTRUCTIONS FOR USE INSTALLATION AND MAINTENANCE...

Page 31: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 6 38 dB 00 dB 8 kW 8 kW 8 kW...

Page 32: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 6...

Page 35: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 9 41 dB 00 dB 10 kW 10 kW 10 kW...

Page 36: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 9...

Page 39: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 11 36 dB 00 dB 11 kW 11 kW 11 kW...

Page 40: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11...

Page 44: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11 1x230V...

Page 47: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 14 38 dB 00 dB 14 kW 14 kW 14 kW...

Page 48: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14...

Page 52: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14 1x230V...

Page 55: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 17 42 dB 00 dB 17 kW 17 kW 17 kW...

Page 56: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 17...

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......