18

100% GEOTHERMAL HEAT

18

INSTALLER MANUAL

The storage tank is to be filled with special care through the group of fill

valves included in the system so that the storage tank pressure never

exceeds 1.5 bar. While filling the storage tank, the air inside it must be

allowed to escape freely and not through air valve or safety valve, for

example. Suomen Lämpöpumpputekniikka Oy cannot be held respon

-

sible for any expenses resulting from storage tank breakage in situations

where the tank has not been filled with water pursuant to the above

instructions.

NOTE! Maximum storage tank pressure is 1.5 bar!

The pipes in the heating network are connected to the ground source heat

pump using either textile hoses (network of radiators) or using a fixed

piping network (floor heating). These connections prevent sound from

passing into the network. All heating connections (for example, a heating

radiator for an air conditioner or a heated towel rail) must be made to the

heat distribution circuits, not domestic hot water. When the network pip

-

ing is in place, filling may commence.

Storage tank and heating system filling and de-aeration

There must be a de-aeration valve in the same branch with the group of

fill valves. The expansion vessel may be in the same branch as well. The

pipes in the network are filled with water. Note! If renovating, ensure that

the heat distribution piping has been properly rinsed before connecting the

geothermal heat pump.

Filling and de-aerating a heating system fitted with a pressure gauge:

•

Open the fill valve on the heating network.

•

Fill the network with water.

•

De-aerate the storage tank and network until all the air has been

removed and leave the pressure at 1-1.2 bar (max. 1.5 bar).

•

Maximum pressures:

•

Heating network storage tank – 1.5 bar

•

Domestic hot water circuit – 9 bar

Domestic hot water connections and circulation of water

If there is no domestic hot water circulation at the site, make connections

pursuant to HVAC diagrams annexed to these instructions. Domestic

water is connected to the ground source heat pump pursuant to the pic

-

ture in Section 4.2.3. The same picture is provided on top of the unit. The

mixing valve is fitted to the hot water pipe in order to prevent burns. The

overflow pipe is joined to the floor drain as instructed or to an overflow

funnel if the distance to the floor drain is more than two metres. The

overflow funnel must be directed down towards the floor drain. The back

-

pressure valve is fitted to the cold water joint on the input side. See the

annexed HVAC connections diagram.

If DHW circulation is installed to the system should circulation pump to

be installed to the DHW return pipe. DHW coil in the model Vmi has two

seperate sections. When there is no water consumption temperature level

of the circulation is maintained by circulating water only in the upper tank

coil. This avoids mixing of the temperature levels inside a tank. In a nor

-

mal circumstances coils are connected to copper coil which is located on

a roof of the heat pump. When installing DHW circulation ½” plug –

visible in the picture below – will be removed and all connections are

implemented according the HVAC scheme.

If there is domestic hot water circulation at the site, install the water cir

-

culation pump to the domestic water line returning to the heat pump. In

case of the Vmi series, the domestic hot water coil has been divided into

two parts. If there is no domestic water consumption, the coil temperature

level is maintained by circulating water only in the upper storage tank coil.

This way, blending of storage tank temperature stratifications is avoided.

Under normal circumstances, the coils are connected using a copper

elbow located on top of the heat pump. The elbow is cut and connections

made according to the annexed HVAC diagram.

If the ground source heat pump is located far from the building heated or

if heat losses are exceptionally high, for the purposes of optimal ground

source heat pump operation, we recommend installation of a small addi

-

tional heat source (e.g., ÄssäStream heating convector or approx. 20-30 l

electric water heater).

NOTE! External radiators or dryers may not be connected to domestic hot

water circulation!

4.2.4. HVAC checklist

Check that

•

the joints are tight and there are no leaking valves

•

the expansion vessel on the heating system and fill side is

properly installed

•

the overflow pipe on the safety valve and the pressure gauge on

the heating system have been properly installed

Summary of Contents for VMI 6-17

Page 1: ...L MP SS Vmi 6 17 L MP SS 3 2016 INSTRUCTIONS FOR USE INSTALLATION AND MAINTENANCE...

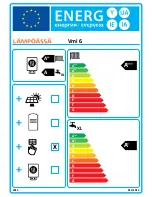

Page 31: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 6 38 dB 00 dB 8 kW 8 kW 8 kW...

Page 32: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 6...

Page 35: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 9 41 dB 00 dB 10 kW 10 kW 10 kW...

Page 36: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 9...

Page 39: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 11 36 dB 00 dB 11 kW 11 kW 11 kW...

Page 40: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11...

Page 44: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11 1x230V...

Page 47: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 14 38 dB 00 dB 14 kW 14 kW 14 kW...

Page 48: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14...

Page 52: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14 1x230V...

Page 55: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 17 42 dB 00 dB 17 kW 17 kW 17 kW...

Page 56: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 17...

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......