19

19

INSTALLER MANUAL

•

the heating system has been filled and de-aerated appropriately

•

the ground circuit has been installed, filled and de-aerated

appropriately

4.3. Electrical installation and outdoor sensors

Only qualified electricians are permitted to carry out electrical work on the

heat pump according to general regulations.

Unit

Power supply Fuse size, slow, A

(*in case of part-power)

Vmi 6

400 V 3N~

3x10 (*16)

Vmi 9

400 V 3N~

3x16 (*20)

Vmi 11

400 V 3N~

3x16 (*20)

Vmi 11 1-phase

230 V 1N~

1x32

Vmi 14

400 V 3N~

3x16 (*20)

Vmi 14 1-phase

230 V 1N~

1x40

Vmi 17

400 V 3N~

3x16 (*20)

The Lämpöässä heat pump is connected to a 230 V or 400 V (50 Hz)

electrical network. The Lämpöässä heat pump has been fitted with an

integrated electrical switchboard which is permanently powered. The loca

-

tion of the protection switch for the motor and other tripping devices are in

the electrical switchboard that is inside the heat pump. A plastic-coated

wire is used as a supply line, which wire travels to the master switch in a

casing pipe. The electrical switchboard cover can be removed without

crown panel removal, by undoing four screws on top of the switchboard.

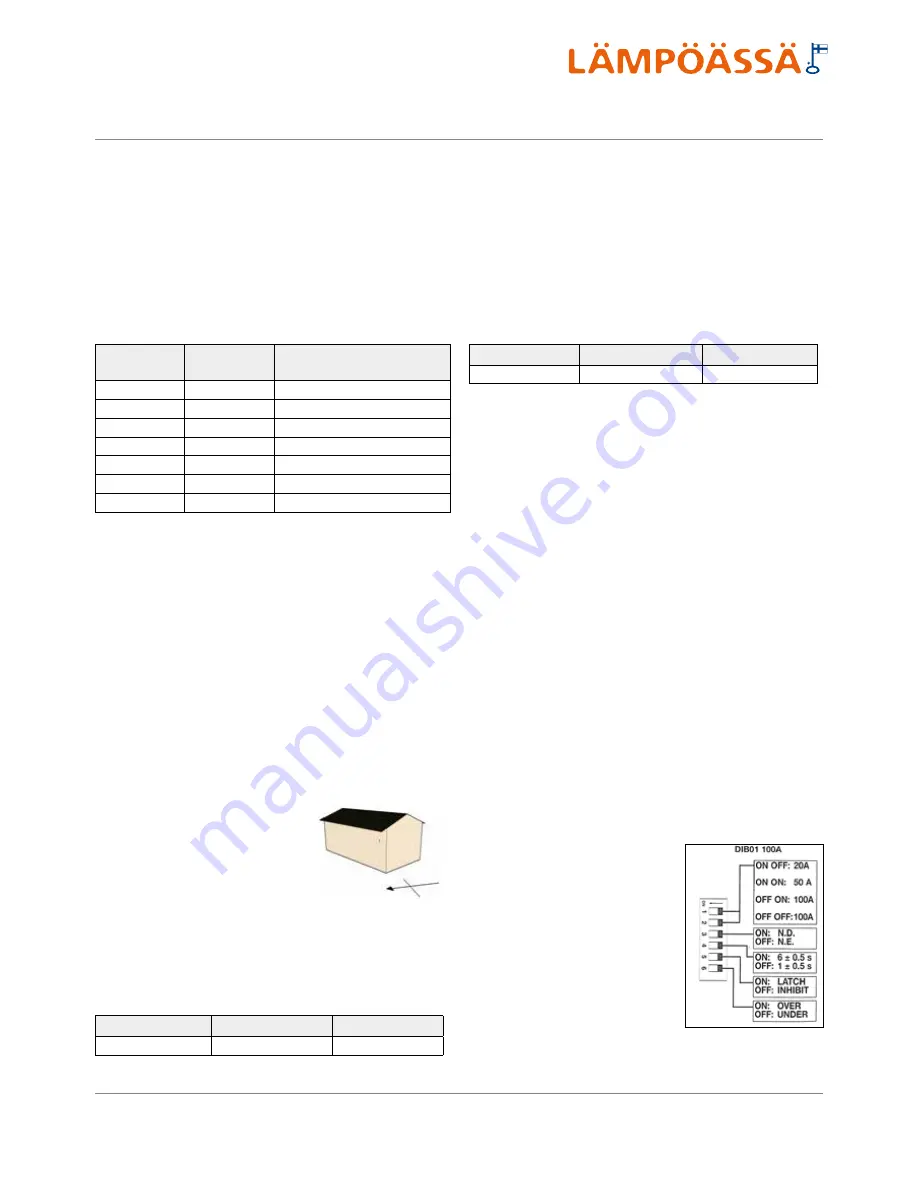

4.3.1. Outdoor sensor

In order for the outdoor sensor to recognise weather conditions as effec

-

tively as possible, it must be placed in the correct location. The outdoor

sensor should be placed on the north-west

-

ern or northern side of the building to avoid

the effects of the morning sun. If the sensor

cannot be placed as recommended, ensure

that this is protected from direct sun light.

The sensor is placed approximately 2/3 of the way up to the wall of the

building near the corner. A sensor should not be placed under a roof, in a

place protected from the wind or over a vent, doors or windows where the

temperature is not the normal outdoor temperature.

Device

Terminal block No. Conductor type

Outdoor sensor NTC

X1/10 ja X1/2

2 X 0,7 mm2

4.3.2. Room sensor (optional)

In order for the room sensor to detect average indoor temperatures as

reliably as possible, it must be placed in a central and open location, for

example a hallway between several rooms or the staircase. String a bipo

-

lar electrical line (at least 0.5 mm2) from the heat pump to the room

sensor. Position the room sensor approximately 2/3 of the way up the

wall. Connect the room sensor lead to the heat pump.

Device

Terminal block No.

Conductor type

Room sensor NTC

X1/14 ja X1/2

2 X 0,7 mm2

4.3.3. Current monitor

If the equipment has been installed in the part-power configuration, load

limiting relays must be installed to the building’s master electrical switch

-

board, if necessary. These relays are intended to reduce the power of the

ground source heat pump’s electric heating element by phases if the

phase current passing through the building’s master fuses approaches the

master fuse nominal current.

Load limiting relays are connected downstream of the master electrical

switchboard’s master fuse so that the entire building’s main current

passes through the relays. Contact data of load limiting relays are wired

by quadrupole cable from the master switchboard to the ground source

heat pump electrical switchboard, where they are connected to the control

circuit diagram. The load limiting relay circuit diagram has been annexed

to these instructions.

Current monitoring relay installations and connection

These settings are initial and may require changing. Relays must always

be adjusted in a case-specific manner.

•

Choose correct current range

•

Turn switch 2 to position ON (if

master fuse size is less than 50A)

•

Other switches 1, 3-6 to position

OFF.

•

Adjust hysteresis, current % and

delay using screws in the front part

(master fuses 25 A)

•

Hysteresis 21

•

Current 25 - 28 %

•

Delay 1s

•

The relay requires external voltage 24-240 V/AC.

Summary of Contents for VMI 6-17

Page 1: ...L MP SS Vmi 6 17 L MP SS 3 2016 INSTRUCTIONS FOR USE INSTALLATION AND MAINTENANCE...

Page 31: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 6 38 dB 00 dB 8 kW 8 kW 8 kW...

Page 32: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 6...

Page 35: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 9 41 dB 00 dB 10 kW 10 kW 10 kW...

Page 36: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 9...

Page 39: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 11 36 dB 00 dB 11 kW 11 kW 11 kW...

Page 40: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11...

Page 44: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11 1x230V...

Page 47: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 14 38 dB 00 dB 14 kW 14 kW 14 kW...

Page 48: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14...

Page 52: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14 1x230V...

Page 55: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 17 42 dB 00 dB 17 kW 17 kW 17 kW...

Page 56: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 17...

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......