20

100% GEOTHERMAL HEAT

20

INSTALLER MANUAL

•

External supply is connected to terminals A1 and A2.

•

Terminals 15 and 16 are connected to geothermal heat pump and

interrupt the heating element’s supply with respect to the phase the

current value of which is exceeded.

•

Each phase must be lead through the relay using the dedicated hole

inside it: L1 for relay 1, L2 for relay 2, L3 for relay 3

No other connections with relay are necessary.

4.3.4. Electrician’s checklist

Check that

•

all phases going to the switchboard are in the correct phase

sequence

•

the master fuse is of sufficient size

•

the ground source heat pump’s fuse size is correct, type: slow (C

curve)

•

if necessary, current monitor has been installed to the building’s

master electrical switchboard (part-power models)

If the ground source heat pump is started for the first time without

pre-heating, compressor will be damaged. Fill the storage tank with

water and prevent the compressor from starting by pressing down the

red compressor motor circuit breaker. Switch on the ground source heat

pump’s power supply, the electric heating element begins to heat the

water contained in storage tank. A regulator alarm goes on and the text

“Compressor 1 circuit 1 some motor protection gone off. Check motor

protection F1, F2 or F3” appears on the display. Later another regulator

alarm goes on and the text “Resistor functioned in full power system”

appears. These alarms do not require taking any measures. Starting of

the compressor is allowed after six hours of pre-heating.

NOTE! A COMPRESSOR STARTED WITHOUT PRE-

HEATING IS NOT COVERED BY WARRANTY!

4.4. Commissioning

Before commissioning, check that:

•

the heating system has been connected, filled and de-aerated

appropriately

•

the ground circuit has been installed, filled and de-aerated

appropriately

•

electrical connections have been made appropriately and the

outdoor sensor (and optional room sensor) has been installed

•

after preventing the compressor from starting, water in the

storage tank has been heated by the electric heating element for

at least 6 hours

Possible problems during startup

Problem

Cause

Solution

Fuses always blow

when the compressor is

started.

You are using the wrong

type of fuse.

Check that the fuse

is automatic: C or D /

ceramic fuse: SLOW or

with a snail icon.

Temporary connections

at the site are causing an

overload of the fuses

Reduce load.

The heat collection

circuit pump does not

start.

The regulator may not be

getting any power.

Check the regulator fuse.

The regulator is not au

-

thorised to start the pump.

Check the measured/set

values.

The shut-off valves are in

the fill position.

Check that the de-

aeration and fill valves

are in the closed position

and that the intermedi

-

ate valve is open.

The heat collection

circuit’s water circulation

pump motor protection

switch has gone off.

Reset the motor protec

-

tion switch and check

the set values from

electrical diagram.

The compressor runs

for a little while and

the evaporator pressure

switch goes off.

There may still be air in

the heat collection circuit.

De-aerate the heat col

-

lection circuit.

There may be a leak in the

refrigerant circuit.

Contact the equipment

installer or dealer.

The fluid level in the

heat collection circuit fill

container drops suddenly

after startup.

There is a leak in the

system (the smell of ethyl

alcohol or glycol is strong),

there is a leak in the heat

collection circuit or there

is still air in the circuit.

Check the condition of

valves in the de-aeration

group, air valve and the

shaft seal on the ground

circuit pump, check the

condition of heat col

-

lection circuit extension

joints, or de-aerate.

Motor protection

switches go off when

starting.

The compressor or the

ground circuit pump is

short-circuited or one

of the phases is not

activated.

Check electrical connec

-

tions.

The fuses in the master

switchboard of the build

-

ing have blown or are

faulty.

Check and replace fuses

as required.

The maintenance menu section Manual control allows manual control of

compressors, pumps and valves. This facilitates troubleshooting process

and may be of help in case of starting problems.

Summary of Contents for VMI 6-17

Page 1: ...L MP SS Vmi 6 17 L MP SS 3 2016 INSTRUCTIONS FOR USE INSTALLATION AND MAINTENANCE...

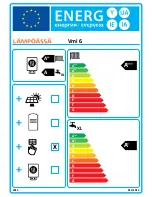

Page 31: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 6 38 dB 00 dB 8 kW 8 kW 8 kW...

Page 32: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 6...

Page 35: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 9 41 dB 00 dB 10 kW 10 kW 10 kW...

Page 36: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 9...

Page 39: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 11 36 dB 00 dB 11 kW 11 kW 11 kW...

Page 40: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11...

Page 44: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11 1x230V...

Page 47: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 14 38 dB 00 dB 14 kW 14 kW 14 kW...

Page 48: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14...

Page 52: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14 1x230V...

Page 55: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 17 42 dB 00 dB 17 kW 17 kW 17 kW...

Page 56: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 17...

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......