22

100% GEOTHERMAL HEAT

22

MAINTENANCE MANUAL

Use the button in the bottom left corner to return to the home screen. Use the arrow button in the bottom right corner to return to previous screen.

For instructions screen, press the ‘i’ button in the top right corner. In case of operation faults, an alarm button is displayed on the top bar.

The system does

not produce enough

heat.

A sudden drop in outdoor

temperature may temporari

-

ly cause inadequate heating

power in new buildings,

because moisture contained

in the structure takes up a

lot of heat when it dries.

No action required.

During the first year, the

ground circuit may not

produce heat at full power

because the earth around

the ground circuit pipes has

not yet become more solid.

No action required.

In the Measurements

screen, the set value

and measured value

do not match.

Some active correction

function (for example, timer

or home/away) is adjusting

the original set value.

The active correction func

-

tion can be deactivated, if

required.

A spiking over-voltage caus

-

ed by a lightning strike has

caused a fault in the regu

-

lator (not under warranty),

causing the temperature to

drop from the actual values.

Replace the regulator (not

under warranty).

The regulator motor has

been set on manual and

the regulation does not take

place.

Return the heat distribution

circuit adjustment motor to

automatic mode.

In summer, when the

building indoor temperature

exceeds the value adjusted,

the supply water tempera

-

ture sensor indicates higher

readings as compared to the

adjustment curve, due to

rise in the heat distribution

circuit temperature.

No action required.

The compressor is

on all the time or for

long periods of time.

A lot of heat is needed, for

example the outdoor tem

-

perature is very low or the

structure is drying during

the first year’s use of the

building.

No action required.

Lack of refrigerant. Can be

detected from bubbles in

the liquid container even

after some minutes of use.

Contact a refrigeration supp

-

lier or maintenance

If these instructions do not help, please contact the equipment installer

or your local dealer. If necessary, contact the Lämpöässä maintenance

call centre at +358 40 841 8340.

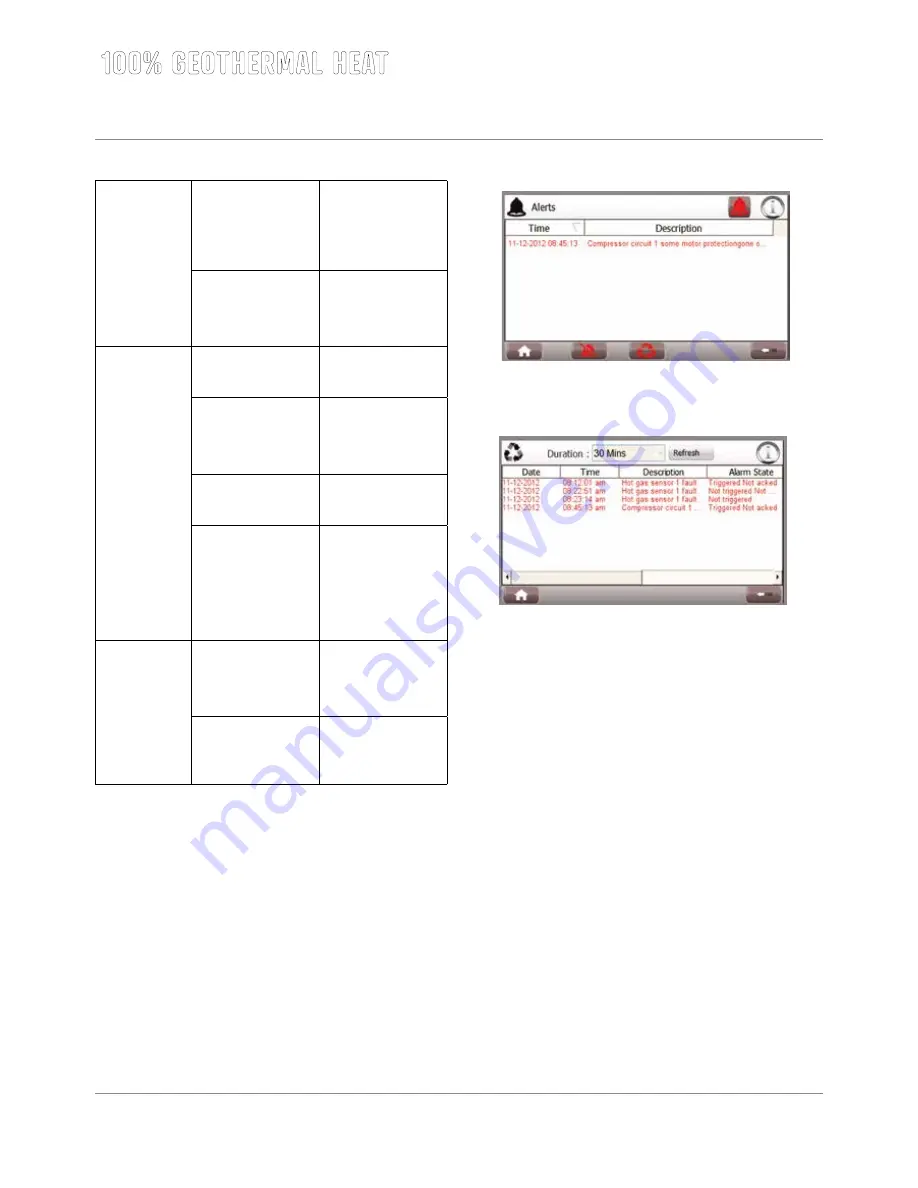

5.3. Alarms

There are two ways to examine the alarms with ÄssäControl.

•

You can see the active alarms if you press the alarm bell on front

page. You can check out the alarms by pressing the check out

alarms -button. You can go to alarm history from active alarms page

by pressing the button at the bottom of the page.

•

You can see earlier alarms by pressing the alarm history -button at

the menu functions.

The software automatically stores the newest 100 fault messages. This

menu allows resetting the fault log data stored. Possible alarms in Vmi

ground source heat pump:

•

Compressor 1 circuit 1 some motor protection gone off. Check

motor protection F1, F2 or F3.

•

Compressor 1 internal heat protection gone off. Wait 45 min.

•

Low pressure pressostat of circuit 1 functioned. Accept presostat.

•

High pressure pressostat of circuit 1 functioned. Accept presostat.

•

Incorrect phase order. Change feed phase order.

•

Temperature did not rise in pre set time. Resistance enabled.

•

Not started information from compressor 1.

•

Disturbance alarm from soft starter AK1 or AK4.

•

Outside temperatur sensor fault.

•

Hot gas sensor 1 fault.

•

Low boiler sensor fault.

•

Top boiler sensor fault.

•

Heating circuit 1 sensor fault.

•

Heating circuit 2 sensor fault.

•

Heating circuit 3 sensor fault.

•

Hot water temperature sensor fault

•

Room temperature sensor fault.

•

Alarm of liquid circuit

•

External alarm

•

Resistor functioned in full power system

Summary of Contents for VMI 6-17

Page 1: ...L MP SS Vmi 6 17 L MP SS 3 2016 INSTRUCTIONS FOR USE INSTALLATION AND MAINTENANCE...

Page 31: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 6 38 dB 00 dB 8 kW 8 kW 8 kW...

Page 32: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 6...

Page 35: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 9 41 dB 00 dB 10 kW 10 kW 10 kW...

Page 36: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 9...

Page 39: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 11 36 dB 00 dB 11 kW 11 kW 11 kW...

Page 40: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11...

Page 44: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 11 1x230V...

Page 47: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 14 38 dB 00 dB 14 kW 14 kW 14 kW...

Page 48: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14...

Page 52: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 14 1x230V...

Page 55: ...XL 2015 811 2013 A A A B C D E F G A A A B C D E F G Vmi 17 42 dB 00 dB 17 kW 17 kW 17 kW...

Page 56: ...A A A A A A A A B C D E F G A A A A B C D E F G XL 2015 811 2013 XL X Vmi 17...

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......