12

2

General Safety Instructions

2.2.1.2 Basic Device

Check the following items prior to commissioning:

•

Valves must be assigned correctly to valve outputs on BT300.

•

Correct setting of time parameters.

•

Functioning of flame sensor

–

in case of flame blow-off during operation

–

parasitic light being present during pre-purge period

–

missing flame formation at the end of the safety-period

•

Whether an approved self-checking flame sensor is used as only these types allow con-

tinuous operation.

•

The function of all existing or required input messages such as:

–

air pressure

–

Gas pressure - min / oil pressure - min

–

Safety chain (e.g. STL)

•

Activated valve leakage control function for gas valves if required for application purposes.

–

If so, check/adjust the correct leakage rate determination.

2.2.2

Tasks fulfilled by "authority on the subject" during Approval Test

By specifying the assigned DIN registration number and product ID number the manufacturer

confirms that model BT300 burner control system is consistent with type-tested system.

The connection between actuators and actuator elements for fuel and combustion air and also

to any additional actuator elements used must be form-fit.

2.2.2.1 Checking for Correct Parameter Setting in System

While installing and commissioning the plant the person in charge of the plant/heating techni-

cian needs to document the following:

•

Parameter set values

•

Setting values (e.g. curve progressions)

•

Values describing fuel/air ratio control.

This data can be printed using LSB Remote Software or alternatively being kept as a hand-

written note.

Retain this documentation and have it checked by the ’authority on the subject’.

NOTICE

For BT300 parameter settings which deviate from application standards can be carried out in

access level 2. For this reason, check whether the parameter settings are consistent with the

corresponding application standards (e.g. EN 676, EN 267, etc.) or the respective plant has

to be approved separately.

Summary of Contents for BT300 BurnerTronic

Page 2: ......

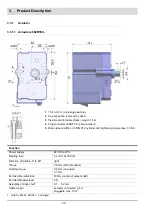

Page 25: ...24 3 Product Description Fig 3 9 Temperature derating BT300 for operation 2000 m NHN...

Page 49: ...48 4 Design and Functions Fig 4 20 Oil with pilot burner BT300...

Page 50: ...49 4 Design and Functions Fig 4 21 Oil without pilot burner BT300...

Page 51: ...50 4 Design and Functions Fig 4 22 Gas with pilot burner and leakage test BT300...

Page 52: ...51 4 Design and Functions Fig 4 23 Gas without pilot burner and leakage test BT300...

Page 53: ...52 4 Design and Functions Fig 4 24 Oil without pilot burner BT335...

Page 54: ...53 4 Design and Functions Fig 4 25 Gas without pilot burner and leakage test BT335...

Page 59: ...58 4 Design and Functions Fig 4 28 Leakage test process diagram...

Page 98: ...97 6 Operating Control and Displays...

Page 99: ...98 6 Operating Control and Displays...

Page 103: ...102 6 Operating Control and Displays...

Page 105: ...104 6 Operating Control and Displays...

Page 106: ...105 6 Operating Control and Displays...

Page 107: ...106 6 Operating Control and Displays...

Page 109: ...108 6 Operating Control and Displays...

Page 126: ...125 6 Operating Control and Displays 6 3 4 2 Curve Table Fig 6 37 Curve table window...

Page 246: ...242 10 EU Declaration of Conformity 10 EU Declaration of Conformity...

Page 247: ...243 10 EU Declaration of Conformity...