13

2

General Safety Instructions

2.2.2.2 Checking the Fuel/Air Ratio Control System

Save setting values (curve parameters) for actuator elements, fuel and combustion air through

the complete range of burner firing rate in sufficient number.

Select setting values of fuel and combustion air considering combustion chamber pressure,

fuel pressure, temperature and pressure of the combustion air in order to guarantee proper

operation with adequate excess air through the entire range of burner firing rate.

The burner/boiler manufacturer has to document this by measuring reference values of the

combustion process.

2.2.2.3 Checking Burner Sequencer Part

Check the following:

•

Correct setting of time parameters (especially safety and pre-purge periods).

•

Whether an ionisation or approved self-checking flame sensor is used as only these types

allow continuous operation.

•

Functioning of flame sensor

–

in case of flame blow-off during operation

–

parasitic light being present during pre-purge period

–

missing flame formation at the end of the safety-period

•

Check the performance of all available and/or essential incoming signals, such as:

–

Air pressure switch

–

Gas pressure - min./oil pressure - min.

–

Safety interlock chain (e.g. STB)

•

Activated leakage control function for gas valves if required for application purposes.

–

If necessary, ensure a correct leakage quantification.

Summary of Contents for BT300 BurnerTronic

Page 2: ......

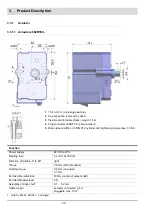

Page 25: ...24 3 Product Description Fig 3 9 Temperature derating BT300 for operation 2000 m NHN...

Page 49: ...48 4 Design and Functions Fig 4 20 Oil with pilot burner BT300...

Page 50: ...49 4 Design and Functions Fig 4 21 Oil without pilot burner BT300...

Page 51: ...50 4 Design and Functions Fig 4 22 Gas with pilot burner and leakage test BT300...

Page 52: ...51 4 Design and Functions Fig 4 23 Gas without pilot burner and leakage test BT300...

Page 53: ...52 4 Design and Functions Fig 4 24 Oil without pilot burner BT335...

Page 54: ...53 4 Design and Functions Fig 4 25 Gas without pilot burner and leakage test BT335...

Page 59: ...58 4 Design and Functions Fig 4 28 Leakage test process diagram...

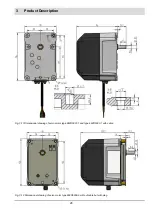

Page 98: ...97 6 Operating Control and Displays...

Page 99: ...98 6 Operating Control and Displays...

Page 103: ...102 6 Operating Control and Displays...

Page 105: ...104 6 Operating Control and Displays...

Page 106: ...105 6 Operating Control and Displays...

Page 107: ...106 6 Operating Control and Displays...

Page 109: ...108 6 Operating Control and Displays...

Page 126: ...125 6 Operating Control and Displays 6 3 4 2 Curve Table Fig 6 37 Curve table window...

Page 246: ...242 10 EU Declaration of Conformity 10 EU Declaration of Conformity...

Page 247: ...243 10 EU Declaration of Conformity...