237

8

Options

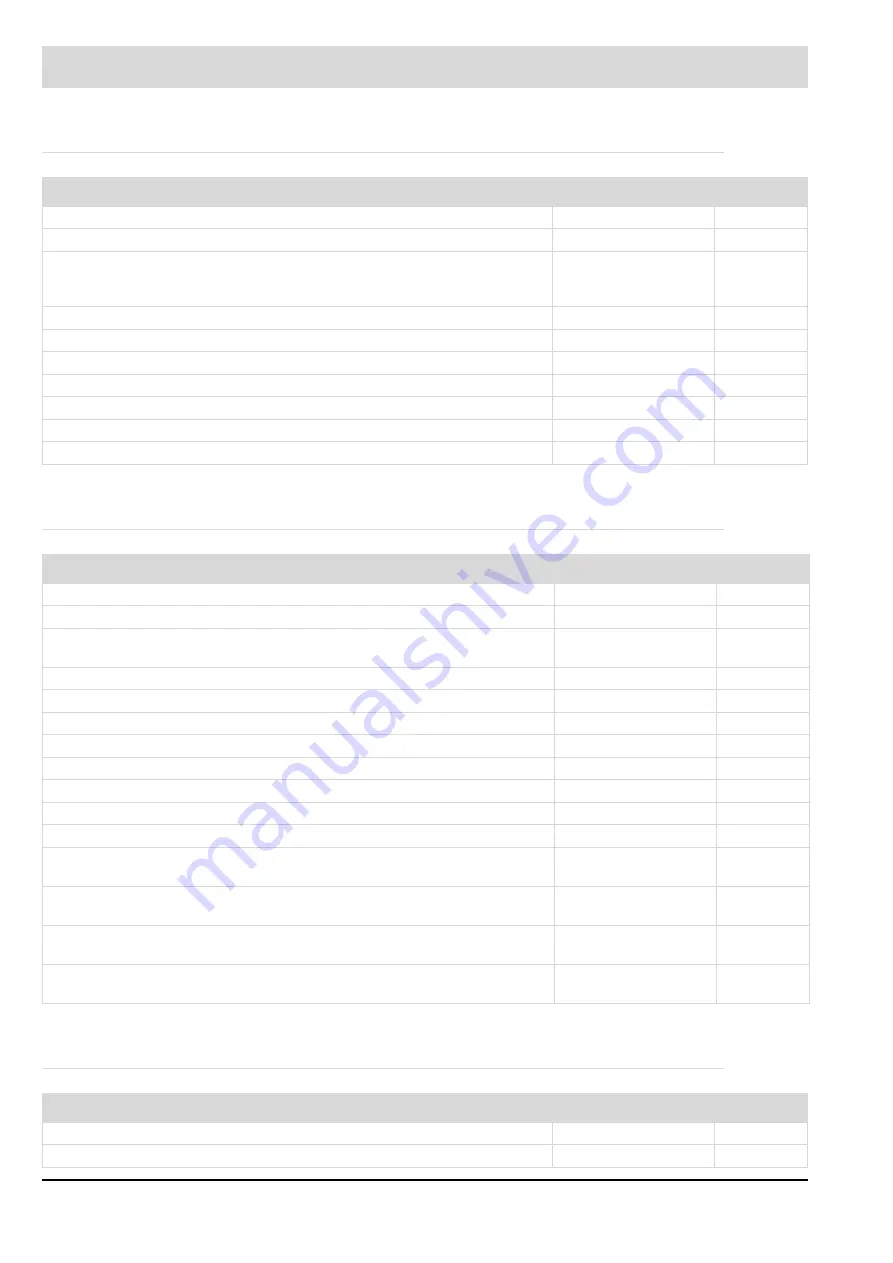

8.5.4.10 Bit Encoding: State of Actual Value of CO

Tab. 8-20 Bit encoding: State of CO actual value

8.5.4.11 Bit Encoding: Cause of Fault of CO Controller

Tab. 8-21 Bit encoding: Cause of faults of CO controller

8.5.4.12 Bit Encoding: State of Flue Gas Temperature and Efficiency

Status CO Actual Value

Bit Pattern

HEX Code

CO threshold has not been triggered.

0000 0000 0000 0001

0x0001

CO threshold has been triggered or has been exceeded.

0000 0000 0000 0010

0x0002

Threshold signal cannot be detected by the transmitting device

0000 0000 0000 0011

0x0001 and

0x0002 are

not set

Underflow

0000 0010 0000 0000

0x0200

Overflow

0000 0100 0000 0000

0x0400

Maintenance mode

0000 1000 0000 0000

0x0800

Sending the replacement value.

0001 0000 0000 0000

0x1000

Warning of the measurement value

0010 0000 0000 0000

0x2000

Failure of the measurement value

0100 0000 0000 0000

0x4000

Invalid measurement value

1000 0000 0000 0000

0x8000

Cause of Fault

Bit Pattern

HEX Code

No valid threshold information available on LSB.

0000 0000 0000 0001

0x0001

The probe voltage is outside the monitoring range.

0000 0000 0000 0010

0x0002

The probe offset voltage is outside the monitoring range or the probe dynamics

cannot be detected.

0000 0000 0000 0100

0x0004

The cell’s inner resistance is outside the monitoring range.

0000 0000 0000 1000

0x0008

The cell temperature is outside the monitoring range.

0000 0000 0001 0000

0x0010

The dynamics of the probe voltage cannot be detected.

0000 0000 0010 0000

0x0020

The internal firing rate is outside the parameter set firing rate window.

0000 0000 0100 0000

0x0040

The watchdog processor deactivates the CO controller.

0000 0000 1000 0000

0x0080

The CO controller is deactivated by the LSB.

0000 0001 0000 0000

0x0100

The O

2

monitoring deactivates the CO controller.

0000 0010 0000 0000

0x0200

The effective CO probe voltage U

COe

is outside the monitoring range.

0000 0100 0000 0000

0x0400

The CO controller is deactivated temporarily because the CO threshold is active for

too long.

0000 1000 0000 0000

0x0800

The CO controller is shut-off permanently because the CO threshold signal was

active for too long.

0001 0000 0000 0000

0x1000

The CO controller is shut-off permanently because the CO threshold signal was

active for too long after ignition.

0010 0000 0000 0000

0x2000

The CO controller is shut-off permanently because the CO threshold signal was

active for too long after ignition.

0100 0000 0000 0000

0x4000

Status

Bit Pattern

HEX Code

Underflow

0000 0010 0000 0000

0x0200

Overflow

0000 0100 0000 0000

0x0400

Summary of Contents for BT300 BurnerTronic

Page 2: ......

Page 25: ...24 3 Product Description Fig 3 9 Temperature derating BT300 for operation 2000 m NHN...

Page 49: ...48 4 Design and Functions Fig 4 20 Oil with pilot burner BT300...

Page 50: ...49 4 Design and Functions Fig 4 21 Oil without pilot burner BT300...

Page 51: ...50 4 Design and Functions Fig 4 22 Gas with pilot burner and leakage test BT300...

Page 52: ...51 4 Design and Functions Fig 4 23 Gas without pilot burner and leakage test BT300...

Page 53: ...52 4 Design and Functions Fig 4 24 Oil without pilot burner BT335...

Page 54: ...53 4 Design and Functions Fig 4 25 Gas without pilot burner and leakage test BT335...

Page 59: ...58 4 Design and Functions Fig 4 28 Leakage test process diagram...

Page 98: ...97 6 Operating Control and Displays...

Page 99: ...98 6 Operating Control and Displays...

Page 103: ...102 6 Operating Control and Displays...

Page 105: ...104 6 Operating Control and Displays...

Page 106: ...105 6 Operating Control and Displays...

Page 107: ...106 6 Operating Control and Displays...

Page 109: ...108 6 Operating Control and Displays...

Page 126: ...125 6 Operating Control and Displays 6 3 4 2 Curve Table Fig 6 37 Curve table window...

Page 246: ...242 10 EU Declaration of Conformity 10 EU Declaration of Conformity...

Page 247: ...243 10 EU Declaration of Conformity...