PAGE 4

ADDITIONAL PROGRAMMING INFORMATION AVAILABLE FROM

LANCASTER WATER TREATMENT UPON REQUEST.

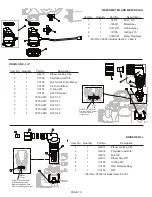

SET HARDNESS, DAYS OVERRIDE & REGENERATION TIME

STEP 1: Press

NEXT

and ▲ simultaneously for 3 seconds.

STEP 2:

Hardness:

Set the amount of hardness in grains of hardness

as calcium carbonate per gallon using the ▲ or ▼ buttons. The

default is 20. The available range is 1 to 150 in 1 grain increments.

STEP 3: Press

NEXT

. Regen day: This sets the maximum number of days

between regenerations. This days override feature can be shut off

by pressing the ▼ button until “OFF” appears. Set the maximum

number of days between by pressing ▲ or ▼. Range is 1– 28

days. If the OFF position is selected, the softener will regenerate

based solely on the gallons capacity.

STEP 4: Press

NEXT

. Regeneration time (hour): Set the hour of the day for

regeneration to occur by using ▲ or ▼ buttons. AM/ PM toggles

after 12. The default time is 2:00 am.

STEP 5: Press

NEXT

. Regeneration time (minutes): Set the minutes of the

day for regeneration by using ▲ or ▼ buttons. Press

NEXT

to exit

Displays/Settings. Current time of day will be displayed.

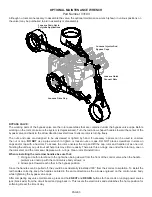

PLACING UNIT INTO SERVICE:

Make sure inlet and outlet valves are to their closed positions. If using optional

bypass, place in bypass position. Turn on main water supply. Open a cold water faucet. This will clear the lines of any debris

(solder, pipe dope, etc.) that may be in the line. Let water run at tap for a couple of minutes, or until clear. Turn off faucet.

Manually add 1½ gallons of water to the brine tank.

•

Press and hold the

REGEN

button for approximately 5 seconds until the motor starts.

•

Wait until display reads

BACKWASH

and numbers start counting down.

•

Momentarily press

REGEN

again. Wait until display reads

BRINE

and numbers start counting down.

•

Momentarily press

REGEN

again. Valve is now in the second

BACKWASH

position.

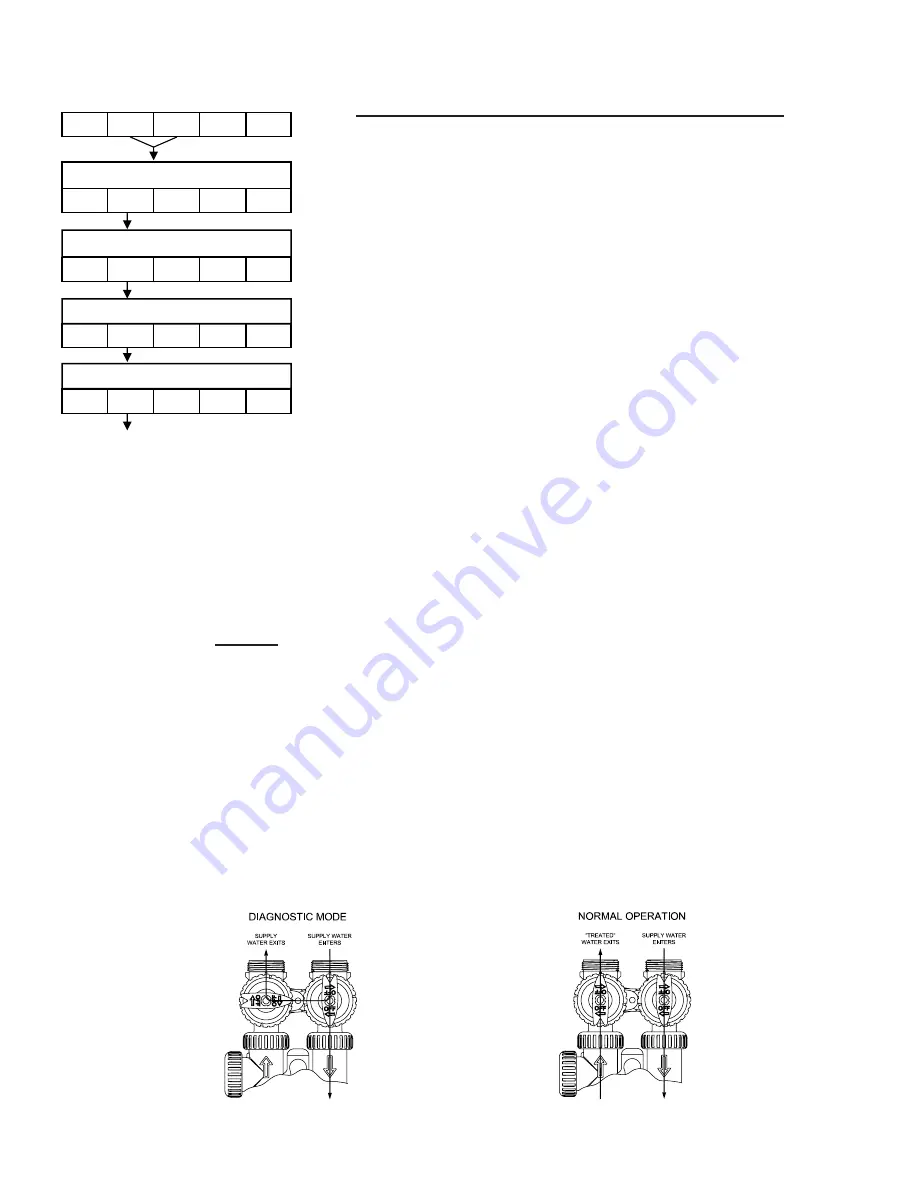

If using optional bypass

SLOWLY

turn bypass valve to

DIAGNOSTIC

position

(figure 2)

or slowly open inlet valve to allow

water to slowly enter the softener.

When water is flowing steadily to drain without the presence of air, momentarily press

REGEN

again. Display will read

RINSE

.

Open the outlet valve of the softener, or if using optional bypass place to

NORMAL OPERATION MODE

(figure 3)

.

Allow control to finish the

RINSE

cycle. It will then advance to the

FILL

position. The brine tank will now automatically fill with

the proper volume of water for the first regeneration.

Allow the control to automatically advance to the

SOFTENING

position.

Load the brine tank with salt. Solar Salt is recommended.

SANITIZING

: Use 2 oz. of 5¼% household chlorine bleach for each cubic foot of resin. Pour bleach directly into the brine

well of the softener. Press and hold the REGEN button for 5 – 6 seconds until the motor starts running. Allow system to

complete the regeneration automatically. Check for other local and state codes which may also specify sanitation methods.

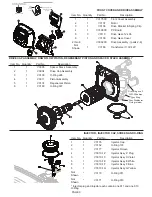

FIGURE 3

FIGURE 2

PLACING UNIT INTO SERVICE:

Make sure inlet and outlet valves are to their closed positions. If using optional

bypass, place in bypass position. Turn on main water supply. Open a cold water faucet. This will clear the lines of any debris

(solder, pipe dope, etc.) that may be in the line. Let water run at tap for a couple of minutes, or until clear. Turn off faucet.

Manually add 1½ gallons of water to the brine tank.

Press and hold the

REGEN

button for approximately 5 seconds until the motor starts.

Wait until display reads

BACKWASH

and numbers start counting down.

Momentarily press

REGEN

again. Wait until display reads

BRINE

and numbers start counting down.

Momentarily press

REGEN

again. Valve is now in the second

BACKWASH

position.

If using optional bypass

SLOWLY

turn bypass valve to

DIAGNOSTIC

position

(figure 2)

or slowly open inlet valve to allow

water to slowly enter the softener.

When water is flowing steadily to drain without the presence of air, momentarily press

REGEN

again. Display will read

RINSE

.

Open the outlet valve of the softener, or if using optional bypass place to

NORMAL OPERATION MODE (figure 3).

Allow control to finish the

RINSE

cycle. It will then advance to the

FILL

position. The brine tank will now automatically fill with

the proper volume of water for the first regeneration.

Allow the control to automatically advance to the

SOFTENING

position.

Load the brine tank with salt. Solar Salt is recommended.

SANITIZING:

Use 2 oz. of 5¼% household chlorine bleach for each cubic foot of resin. Pour bleach directly into the brine

well of the softener. Press and hold the

REGEN

button for 5 – 6 seconds until the motor starts running. Allow system to

complete the regeneration automatically. Check for other local and state codes which may also specify sanitation methods.

STEP 1: Press

NEXT

and ▲ simultaneously for 3 seconds.

STEP 2:

Hardness

: Set the amount of hardness in grains of hardness as

calcium carbonate per gallon using the ▲ or ▼ buttons. The default

is 20. The available range is 1 to 150 in 1 grain increments.

STEP 3: Press

NEXT

. Regen day: This sets the maximum number of days

between regenerations. This days override feature can be shut off

by pressing the ▼ button until “OFF” appears. Set the maximum

number of days between by pressing ▲ or ▼. Range is 1– 28 days.

If the OFF position is selected, the softener will regenerate based

soley on the gallons capacity.

STEP 4: Press

NEXT

. Regeneration time (hour): Set the hour of the day for

regeneration to occur by using ▲ or ▼ buttons. AM/ PM toggles

after 12. The default time is 2:00 am.

STEP 5: Press

NEXT

. Regeneration time (minutes): Set the minutes of the

day for regeneration by using ▲ or ▼ buttons. Press

NEXT

to exit

Displays/Settings. Current time of day will be dislpayed.

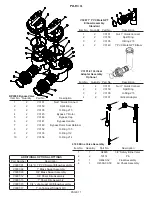

SET HARDNESS, DAYS OVERRIDE & REGENERATION TIME

FIGURE 3

FIGURE 2

SET

CLOCK

NEXT

▲

▼

REGEN

STEP 1

SET

CLOCK

NEXT

▲

▼

REGEN

STEP 4

2:00

AM

SET TIME

SET

CLOCK

NEXT

▲

▼

REGEN

STEP 5

STEP 3

14

SET

20

SET

STEP 2

HARDNESS

REGEN

2:00

AM

SET TIME

REGEN

SET

CLOCK

NEXT

▲

▼

REGEN

REGEN

DAY

SET

CLOCK

NEXT

▲

▼

REGEN

Page 4